Glass, and preparation method and application thereof

A glass, weight percentage technology, used in glass manufacturing equipment, glass forming, glass tempering and other directions, can solve the problems of lack of ductility, strength not meeting expectations, ultra-thin glass scratches, etc., and achieve comprehensive performance improvement. , High breaking strength and mechanical strength, hardness and scratch resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

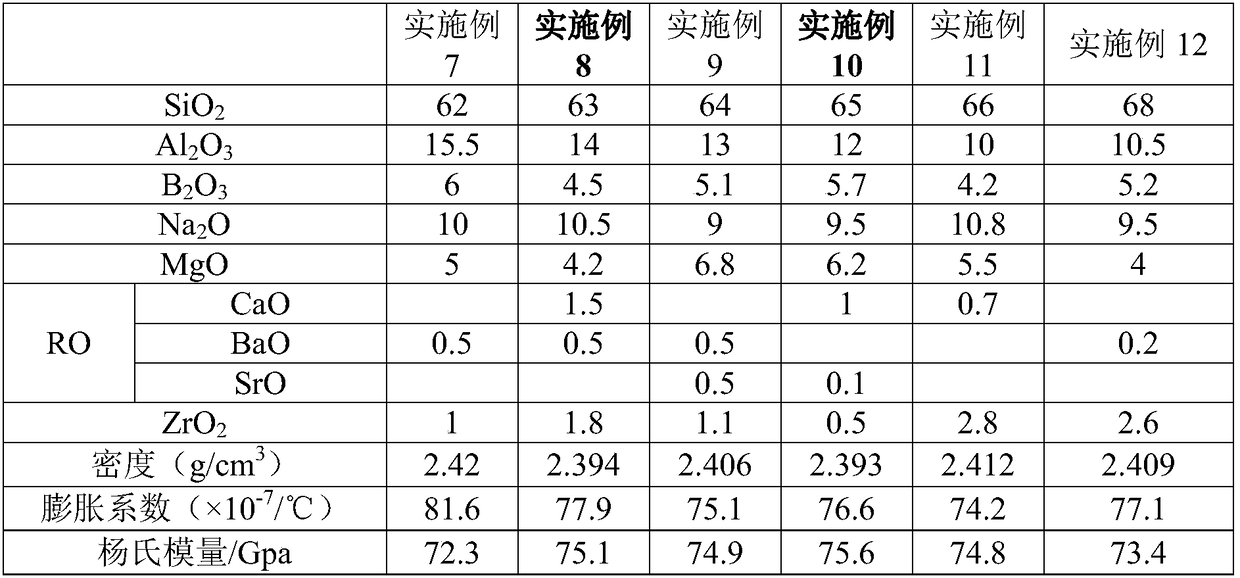

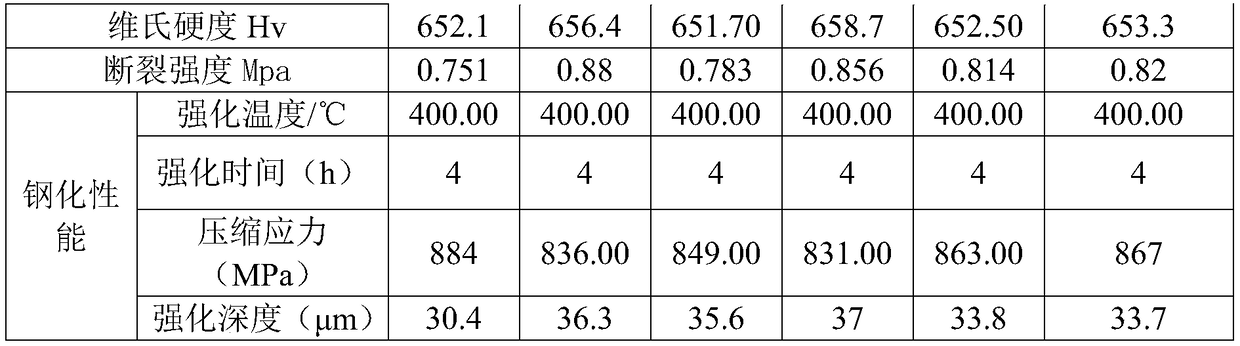

Examples

preparation example Construction

[0029] The method for preparing glass described in the present disclosure may also include processing and performance testing after chemical strengthening. The processing may include slicing and / or polishing. After the glass is annealed and chemically strengthened, it may be processed and processed after the temperature drops to room temperature. Performance Testing.

[0030]According to the second aspect of the present disclosure, the chemical strengthening conditions include: the temperature may be 400-450° C., and the time may be 2-8 hours.

[0031] According to the second aspect of the present disclosure, the melting conditions include: the temperature may be 1450-1630° C., and the time may be 8-12 hours. Preferably, the melting can be carried out in a platinum-rhodium crucible, which conforms to the above-mentioned composition of the glass in the present disclosure, and the melting during the preparation process is carried out in a platinum-rhodium crucible, which is bene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com