A heat treatment method for additively manufacturing single crystal nickel-based superalloys

A technology of nickel-based superalloy and heat treatment method, which is applied in the direction of additive processing, etc., can solve the problems of coarse dendrite, reduced component segregation, slow cooling rate of as-cast superalloy, and achieves simple heat treatment method, improved alloy structure, The effect of optimizing alloy properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (a) Put the additively manufactured single crystal nickel-based superalloy to be processed into a heat treatment furnace for solution heat treatment, raise the temperature to 1270° C., take it out after holding it for 0.5 hours, and use air to cool it for the first time, and cool it to room temperature;

[0039] (b) Place the additively manufactured single-crystal nickel-based superalloy after the first cooling into a heat treatment furnace for an aging heat treatment, raise the temperature to 1080° C., and perform a second cooling after holding the temperature for 6 hours, and cool it to room temperature;

[0040] (c) placing the additively manufactured single crystal nickel-based superalloy after the second cooling into a heat treatment furnace for a second aging heat treatment, raising the temperature to 870°C, and cooling for the third time after keeping the temperature for 20 hours, and cooling to room temperature;

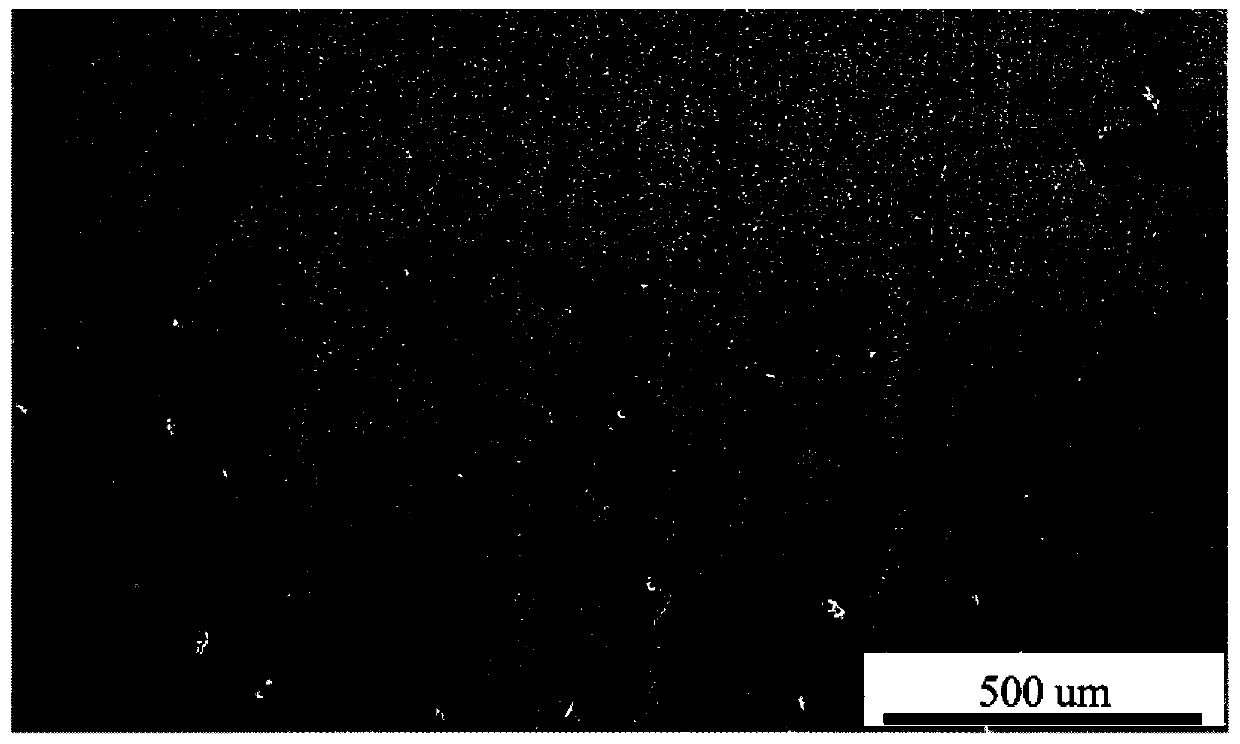

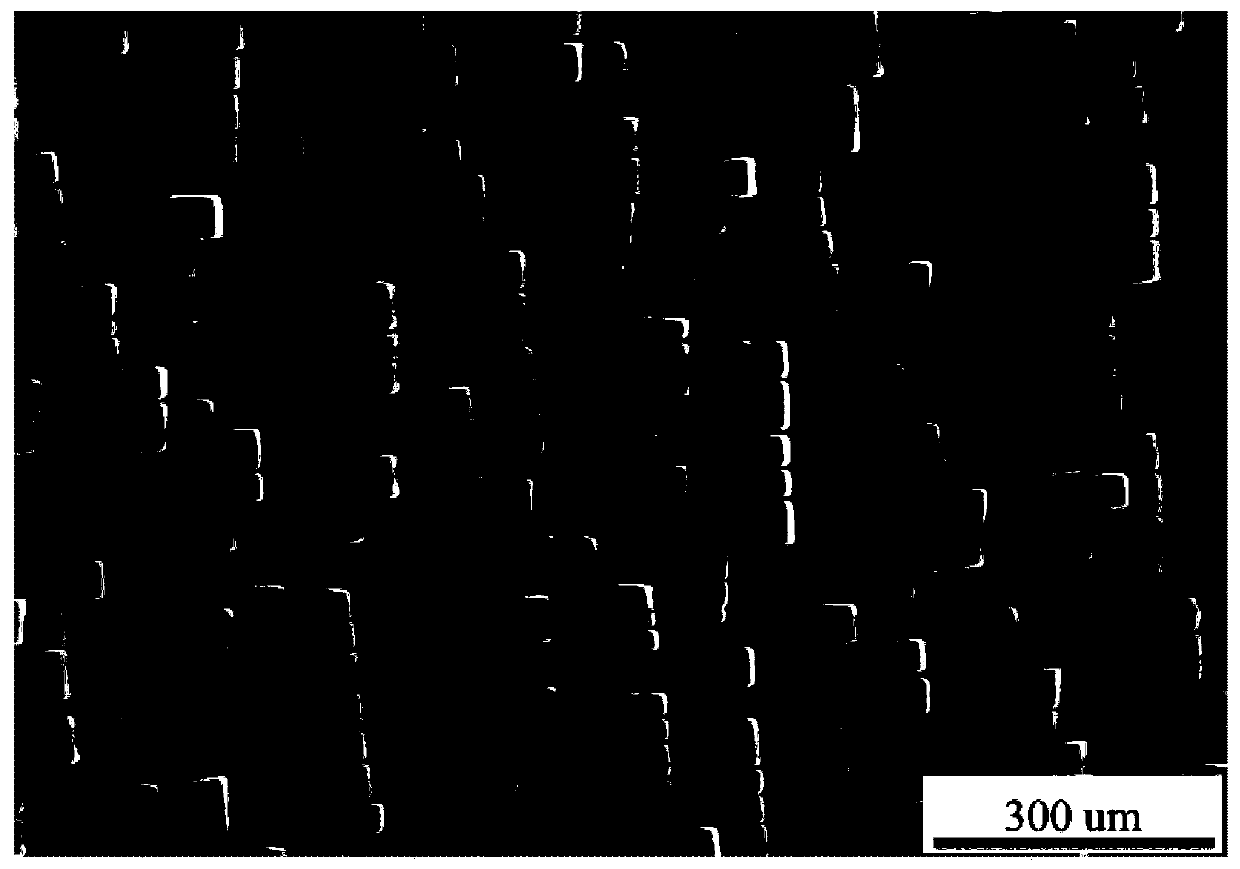

[0041] (d) Slicing the processed additively manuf...

Embodiment 2

[0043] (a) Put the additively manufactured single crystal nickel-based superalloy to be processed into a heat treatment furnace for solution heat treatment, raise the temperature to 1280°C, keep it warm for 1.2 hours, use air for the first cooling, and cool to room temperature;

[0044] (b) Place the additively manufactured single-crystal nickel-based superalloy after the first cooling into a heat treatment furnace for an aging heat treatment, raise the temperature to 1070°C, keep it for 8 hours, and then cool it for the second time to room temperature;

[0045] (c) Place the additively manufactured single-crystal nickel-based superalloy after the second cooling into a heat treatment furnace for a second aging heat treatment, raise the temperature to 840° C., keep it warm for 15 hours, then perform a third cooling, and cool to room temperature;

[0046] (d) Slice samples of the additively manufactured single-crystal nickel-based superalloy after heat treatment, and send it to a...

Embodiment 3

[0050] (a) Clean up the additively manufactured single crystal nickel-based superalloy to be processed, place it in a heat treatment furnace for solution heat treatment, raise the temperature to 1305° C., keep it warm for 3 hours, use air for the first cooling, and cool to room temperature;

[0051] (b) Place the additively manufactured single-crystal nickel-based superalloy after the first cooling into a heat treatment furnace for an aging heat treatment, raise the temperature to 1080° C., and perform a second cooling after holding the temperature for 6 hours, and cool it to room temperature;

[0052] (c) placing the additively manufactured single crystal nickel-based superalloy after the second cooling into a heat treatment furnace for a second aging heat treatment, raising the temperature to 870°C, and cooling for the third time after keeping the temperature for 20 hours, and cooling to room temperature;

[0053] (d) Slice samples of the treated additively manufactured singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com