Method for treating indium-containing high-arsenic soot in wet method

A technology of wet treatment and high-arsenic soot, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of high energy consumption of arsenic open circuit, high production cost, and serious smoke emission, so as to avoid potential safety hazards , Reduce production costs, low processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

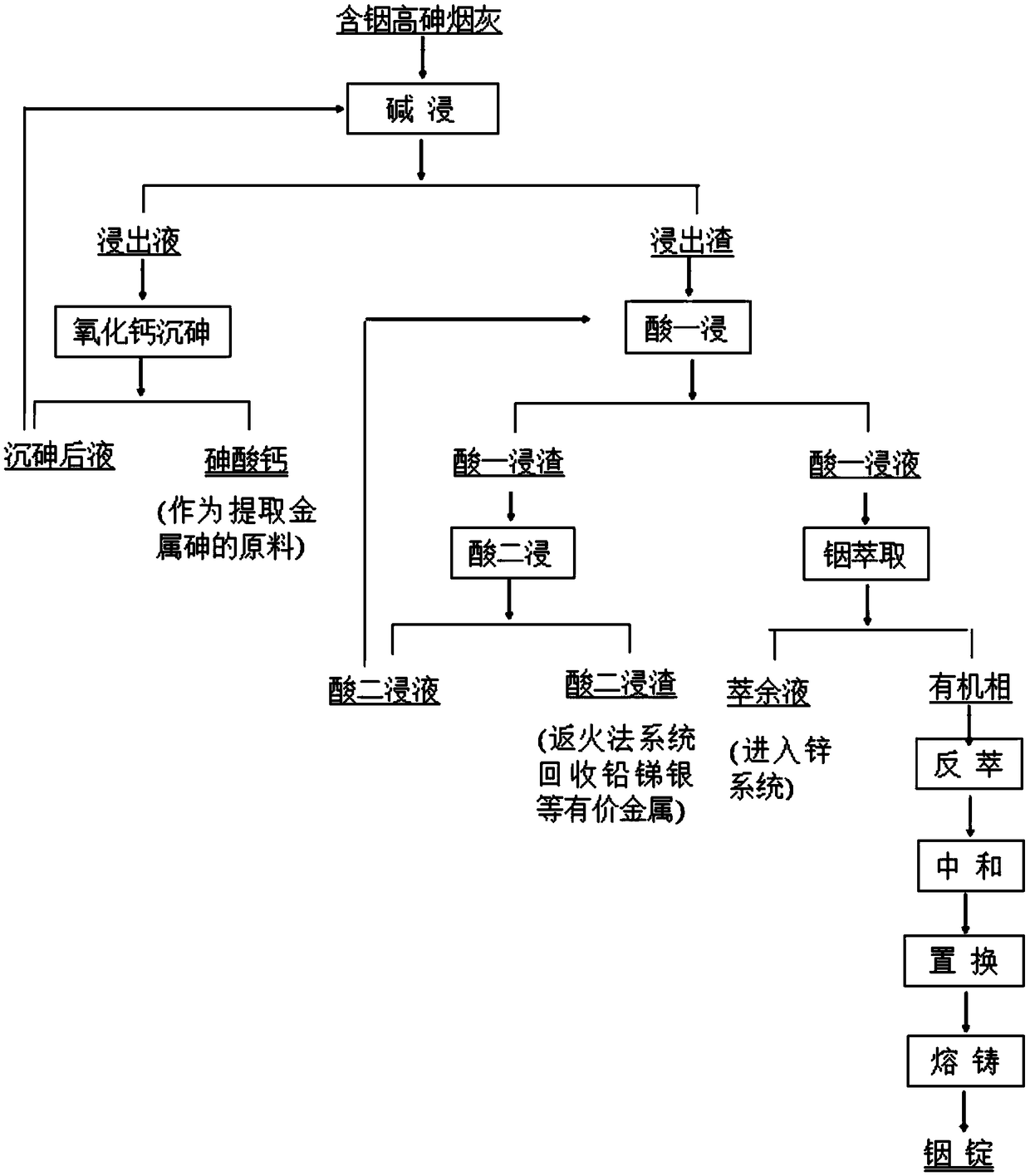

Method used

Image

Examples

Embodiment 1

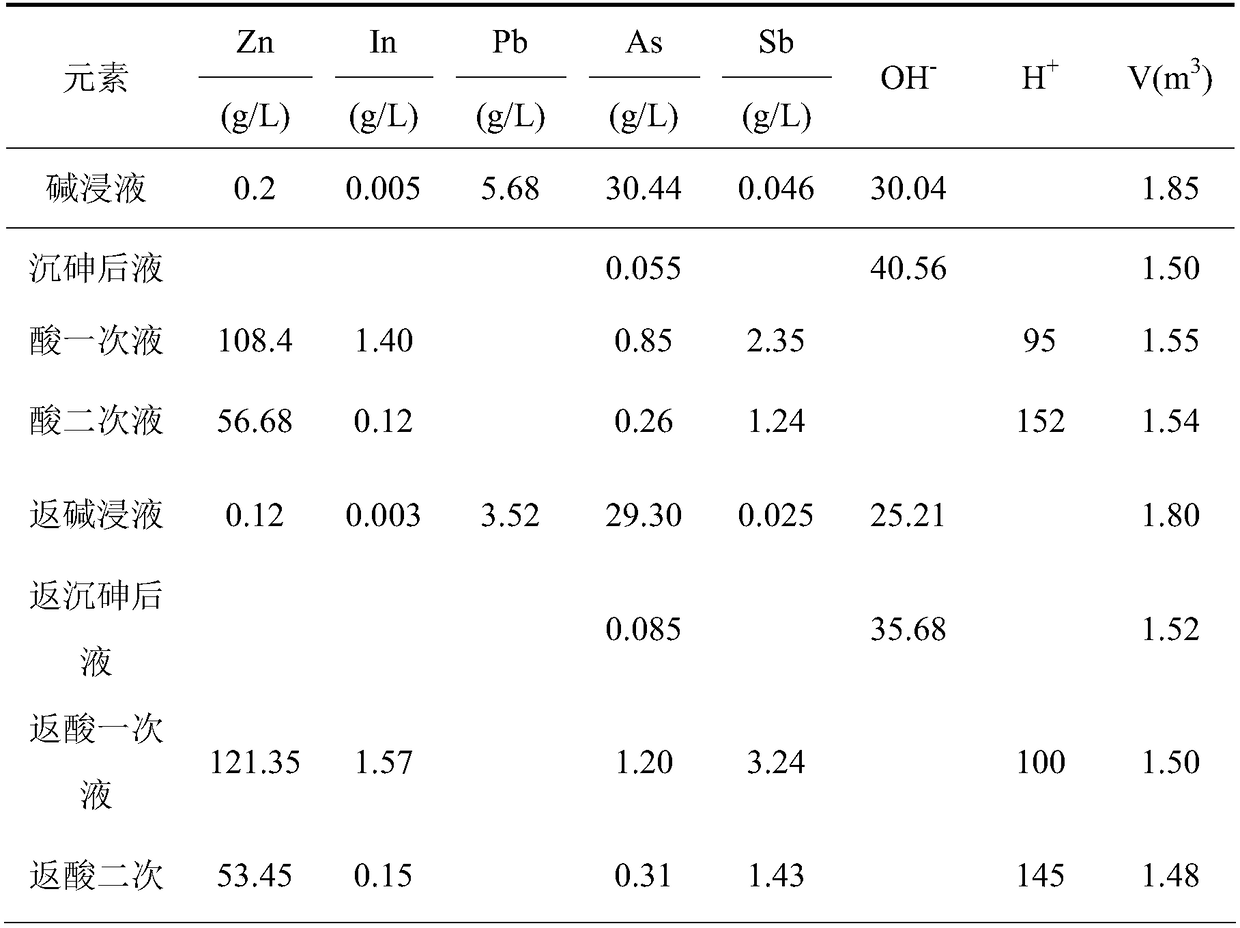

[0025] Take 400kg of indium-containing high-arsenic soot (As: 13.84%, indium: 4562g / t, Sb: 6.28%, Pb: 28.16%, Zn: 30.71%) and pour it into 5m 3 In the reaction tank, add river water 0.8m 3 , 100kg of caustic soda, heat the reaction tank with steam to 70°C and stir the reaction, take 80L of hydrogen peroxide and gradually add it to the solution, the addition time is controlled to 2h, after the reaction time is 2h, continue to add river water to 2.0m 3 , the reaction temperature is 90°C, the reaction time is 2h, and the total reaction time is 4h. After the reaction, liquid-solid separation is carried out, the liquid is subjected to arsenic precipitation treatment, and the residue is subjected to acid leaching. Add 1.6m leaching residue 3 The zinc electrolysis waste liquid is leached with acid once, the reaction temperature is 80°C, the reaction time is 2h, the acidity is controlled by adding concentrated sulfuric acid to control the end point acidity to 100g / L, and 1.6m 3 The...

Embodiment 2

[0032] Take 400kg of indium-containing high-arsenic soot (As: 18.52%, indium: 10246g / t, Sb: 7.65%, Pb: 26.32%, Zn: 35.16%) and pour it into 5m 3 In the reaction tank, add river water 0.8m 3 , 100kg of caustic soda, heat the reaction tank with steam to 75°C and stir the reaction, take 80L hydrogen peroxide and gradually add it to the solution, the addition time is controlled to 2h, after the reaction time is 2h, continue to add river water to 2.4m 3 , the reaction temperature is 90°C, the reaction time is 2h, and the total reaction time is 4h. After the reaction, liquid-solid separation is carried out, the liquid is subjected to arsenic precipitation treatment, and the residue is subjected to acid leaching. Add 2.0m of leaching residue 3 The zinc electrolysis waste liquid is leached with acid once, the reaction temperature is 85°C, the reaction time is 2h, the acidity is controlled by adding concentrated sulfuric acid to control the end point acidity to 110g / L, and 2m 3The z...

Embodiment 3

[0039] Take 400kg of high arsenic soot (As: 22.05%, Indium: 6850g / t, Sb: 5.27%, Pb: 30.42%, Zn: 38.57%) and pour it into 5m 3 In the reaction tank, add river water 0.8m 3 , 120kg of caustic soda, heat the reaction tank with steam to 70°C and stir the reaction, take 80L of hydrogen peroxide and gradually add it to the solution, the addition time is controlled to 2h, after the reaction time is 2h, continue to add river water to 2.4m 3 , the reaction temperature is 90°C, the reaction time is 2h, and the total reaction time is 4h. After the reaction, liquid-solid separation is carried out, the liquid is subjected to arsenic precipitation treatment, and the residue is subjected to acid leaching. Add 2m of leaching residue 3 The zinc electrolysis waste liquid is leached with acid once, the reaction temperature is 80°C, the reaction time is 2h, the acidity is controlled by adding concentrated sulfuric acid to control the end-point acidity to 100g / L, and 2m 3 The zinc electrolysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com