Red copper furnace drawing water pressure stabilization control system

A technology of control system and water stability, which is applied in the field of voltage stabilization control system of copper furnace drawing water, can solve problems such as high uncontrollability, unstable quality of ingot products, and increased tendency of ingot cracks, etc. The effect of casting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

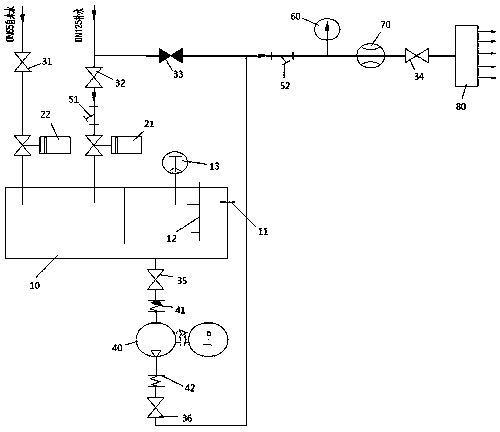

[0015] see figure 1 As shown, the water tank 10 of the copper furnace casting water stabilizing control system of the present invention is equipped with two water inlet channels, which are respectively DN65 tap water pipelines and DN125 water replenishment pipelines, wherein the DN125 replenishment water comes from the on-site water treatment turbid circulation system, which is Normal water supply channel. The DN65 pipeline comes from city tap water, which is water supply channel and cooling water for abnormal situations such as power failure. The tap water in the DN65 tap water pipeline enters the water tank 10 through the first worm gear wafer butterfly valve 31 and the second pneumatic butterfly valve 22 successively.

[0016] The DN125 supplementary water pipeline from the on-site water treatment turbidity circulation system is divided into two parts, one is to enter the water tank 10 through the second worm gear wafer butterfly valve 32, the first Y-type filter 51 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com