Preparation method of plasma assisted super-hydrophobic polyester fabric

A plasma and super-hydrophobic technology, applied in the direction of repelling fibers to liquids, ultrasonic/sonic fiber treatment, fiber types, etc., can solve the problems of difficult processing, great influence on fabric moisture permeability and hand feel, and expensive clothing. , to achieve good mechanical friction stability, easy continuous industrial production, and stable super-hydrophobic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

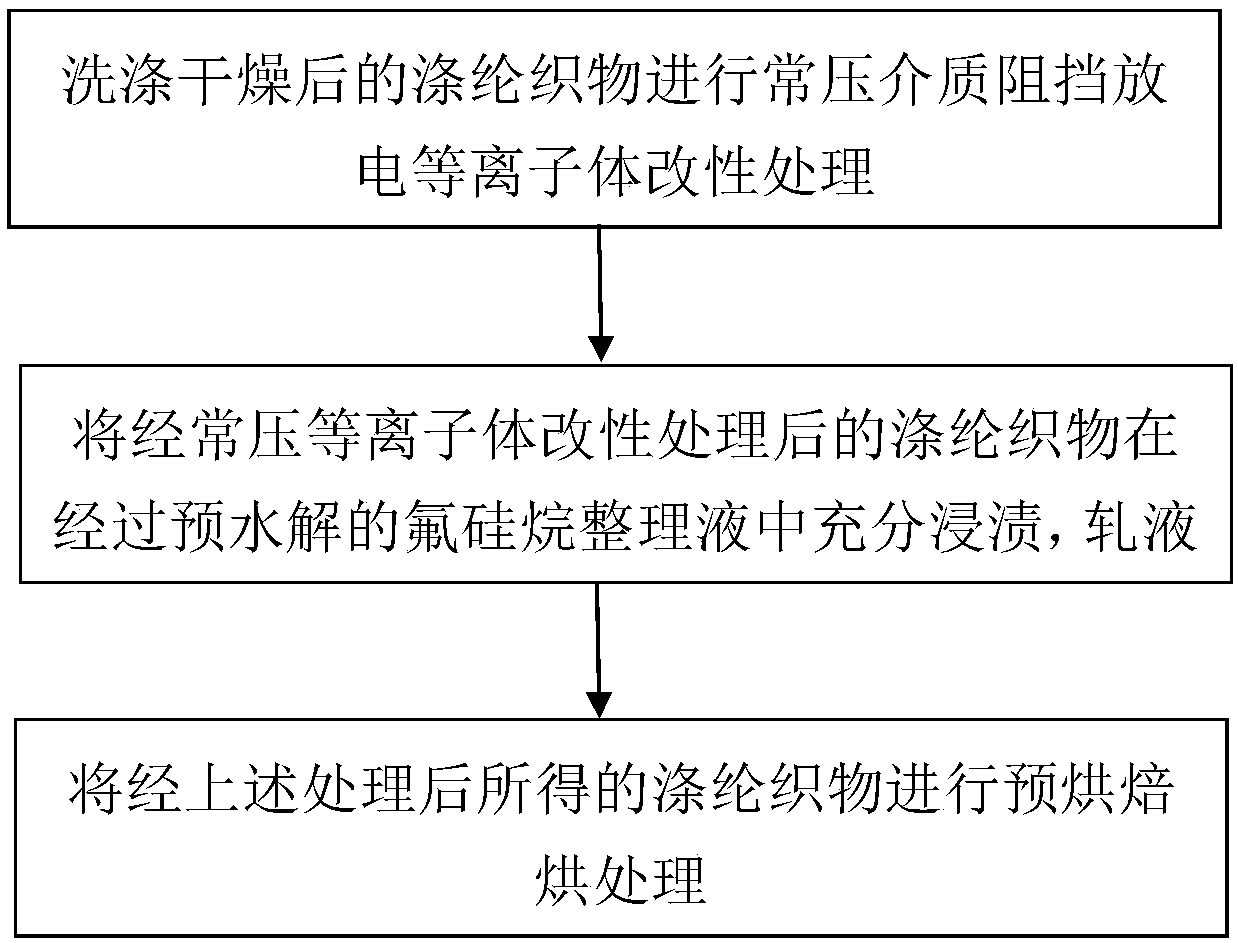

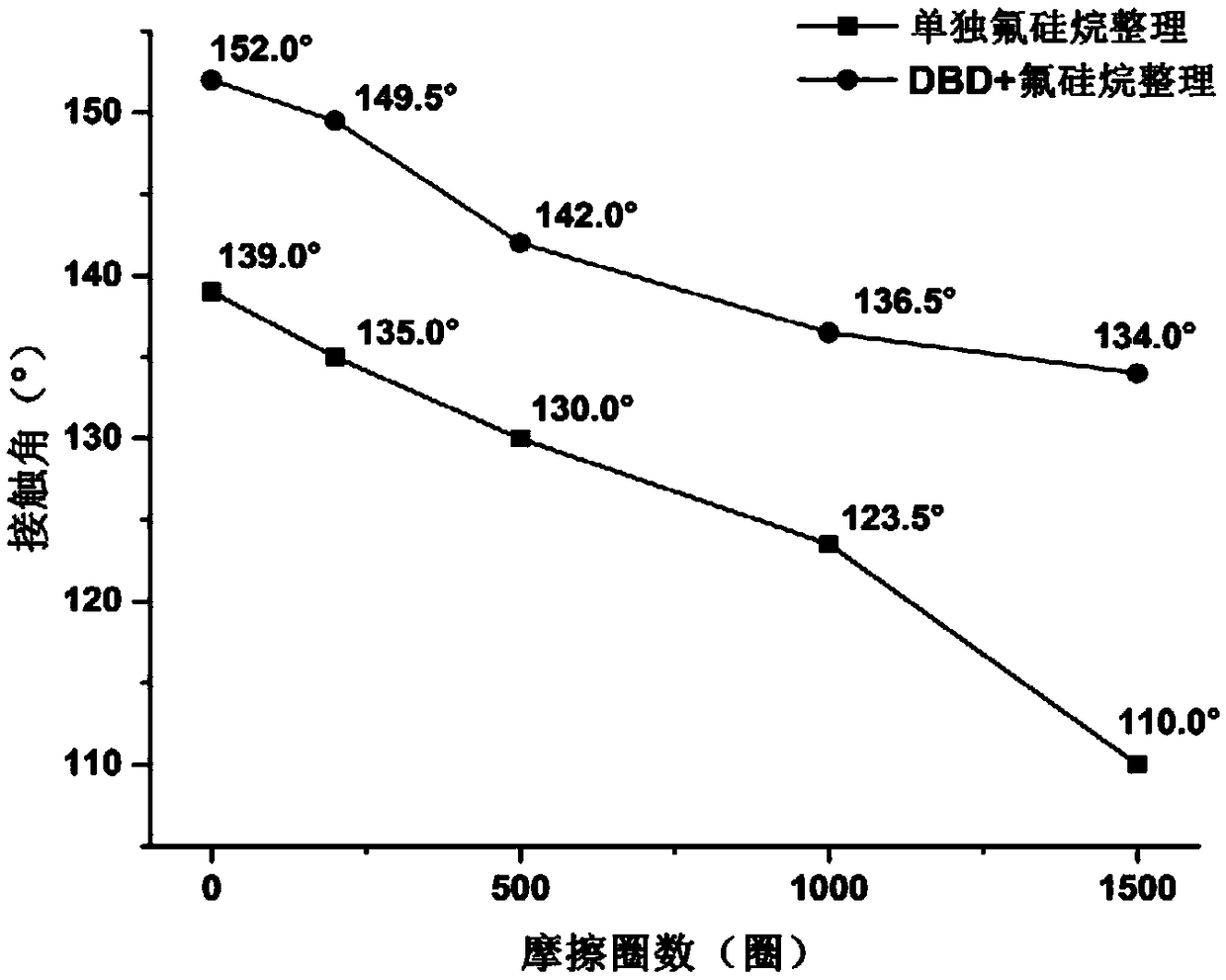

[0021] The invention provides a method for preparing plasma-assisted super-hydrophobic polyester fabric, which combines normal pressure dielectric barrier discharge plasma and a fluorosilane finishing agent to modify the super-hydrophobic properties of polyester fabrics. Atmospheric plasma treatment of polyester fabrics produces a large number of free radicals on the fiber surface, introduces active groups, is energy-saving and environmentally friendly, is easy to operate, and is conducive to continuous production. Fluorosilane finishing agent 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane is a bifunctional compound that is easy to hydrolyze under acidic conditions to release low-molecular alcohol, and then form active silanol, which can be combined with plasma The hydroxyl group and other oxygen-containing groups on the surface of the treated polyester fiber produce stable chemical bonds, which can give the polyester fabric extremely low surface energy and extremely strong and st...

Embodiment 1

[0035] In this embodiment, the plasma assisted superhydrophobic polyester fabric is prepared according to the following steps:

[0036] Wash and dry the surface of the polyester fabric at a temperature of 90°C. The cleaned polyester fabric is subjected to surface treatment in a dielectric barrier discharge atmospheric pressure plasma device, the plasma treatment atmosphere is Ar gas, the gas flow rate is 1L / min, the treatment power is 1KW, and the treatment time is 120s. The polyester fabric modified by normal pressure plasma is fully padded in the pre-hydrolyzed finishing solution, and the solution is prepared according to the bath ratio of 1:40. The finishing solution includes the following raw materials (by mass): fluorosilane finishing agent 1H, 1 part of 1H, 2H, 2H-perfluorooctyltriethoxysilane, 99 parts of absolute ethanol, 100 parts of deionized water, 1 part of acetic acid, of which fluorosilane is pre-hydrolyzed for 30 minutes. Two dips and two rolls, the padding pressu...

Embodiment 2

[0039] In this embodiment, the plasma assisted superhydrophobic polyester fabric is prepared according to the following steps:

[0040] The surface of the polyester fabric is washed and dried at a temperature of 95°C. The cleaned polyester fabric was subjected to surface treatment in a dielectric barrier discharge atmospheric pressure plasma device, the plasma treatment atmosphere was Ar gas, the gas flow rate was 1L / min, the treatment power was 1KW, and the treatment time was 90s. The polyester fabric modified by normal pressure plasma is fully padded in the pre-hydrolyzed finishing solution, and the solution is prepared according to the bath ratio of 1:40. The finishing solution includes the following raw materials (by mass): fluorosilane finishing agent 1H, 1 part of 1H, 2H, 2H-perfluorooctyl triethoxysilane, 99 parts of absolute ethanol, 100 parts of deionized water, 1 part of acetic acid, pre-hydrolysis of fluorosilane for 30 minutes. Two dips and two rolls, the padding pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com