Neutral alcohol transparent silicone sealant and preparation method thereof

A silicone sealant and alcohol-based technology, which is applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of corrosion, unsatisfactory substrate adhesion, and slow curing speed affecting work efficiency, etc. problem, to achieve the effect of solving corrosion, good aging resistance and bonding performance, and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

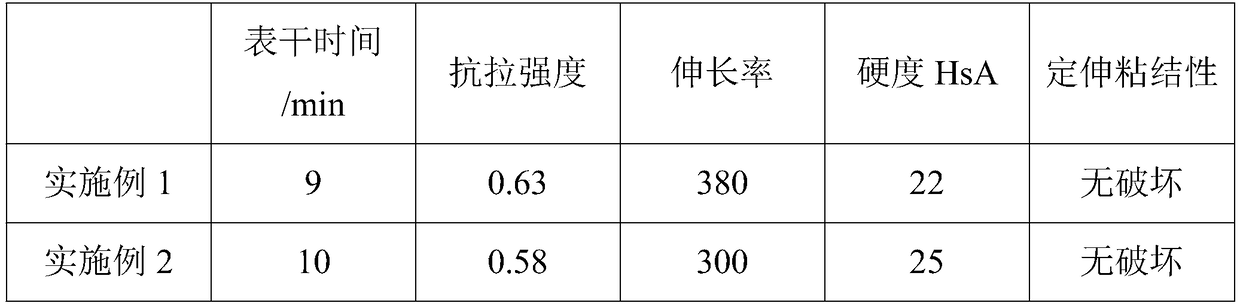

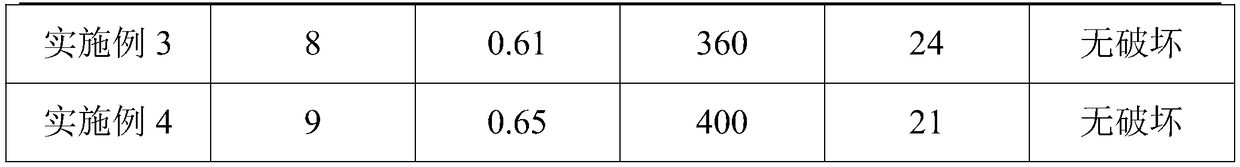

Examples

Embodiment 1

[0024] A neutral alcohol-type transparent silicone sealant, calculated in parts by weight, comprising the following components:

[0025] 53 parts of alkoxy-terminated polydimethylsiloxane, 20 parts of plasticizer, 40 parts of thixotropic agent, 2 parts of crosslinking agent, 7 parts of 3-aminopropyltrimethoxysilane and 1.6 parts of propyl titanate share. The thixotropic agent is a mixture of fumed silica, polyethylene wax and fumed white carbon black. The crosslinking agent is a mixture of ethyl orthosilicate and methyltriethoxysilane.

[0026] The preparation method of plasticizer is:

[0027] Weigh 65wt% methyltrichlorosilane and 35wt% white oil and mix to obtain a mixed monomer, heat up the mixed monomer oil bath to 60°C, add stannous octoate and ethylene glycol under inert gas protection conditions, and react for 1h, Then cool to room temperature and then treat with concentrated hydrochloric acid, then neutralize to neutral with alkali, filter to obtain the filtrate, an...

Embodiment 2

[0033] A neutral alcohol-type transparent silicone sealant, calculated in parts by weight, comprising the following components:

[0034] 45 parts of alkoxy-terminated polydimethylsiloxane, 15 parts of plasticizer, 50 parts of thixotropic agent, 0.1 part of crosslinking agent, 1 part of 3-aminopropyltriethoxysilane and tert-butyl titanate 0.1 part of ester. The thixotropic agent is a mixture of fumed silica, polyethylene wax and fumed white carbon black. The crosslinking agent is a mixture of ethyl orthosilicate and methyltriethoxysilane.

[0035] The preparation method of plasticizer is:

[0036] Weigh 60wt% methyltrichlorosilane and 40wt% white oil and mix to obtain a mixed monomer, heat up the mixed monomer oil bath to 55°C, add stannous octoate and ethylene glycol under inert gas protection conditions, and react for 1.6h , then cooled to room temperature and then treated with concentrated hydrochloric acid, then neutralized to neutral with alkali, filtered to obtain the ...

Embodiment 3

[0039] A neutral alcohol-type transparent silicone sealant, calculated in parts by weight, comprising the following components:

[0040] 60 parts of alkoxy-terminated polydimethylsiloxane, 25 parts of plasticizer, 30 parts of thixotropic agent, 1.7 parts of crosslinking agent, N-(β-aminoethyl)-γ-aminopropyltrimethoxy 10 parts of base silane and 3 parts of tert-butyl titanate. The thixotropic agent is a mixture of fumed silica, polyethylene wax and fumed white carbon black. The crosslinking agent is a mixture of ethyl orthosilicate and methyltriethoxysilane.

[0041] The preparation method of plasticizer is:

[0042] Weigh 70wt% methyltrichlorosilane and 30wt% white oil and mix to obtain a mixed monomer, heat up the mixed monomer oil bath to 50°C, add stannous octoate and ethylene glycol under inert gas protection conditions, and react for 2 hours, Then cool to room temperature and then treat with concentrated hydrochloric acid, then neutralize to neutral with alkali, filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com