A large-scale integral honeycomb ceramic regenerator and its preparation method

A technology of honeycomb ceramics and heat storage body, which is applied in the field of heat storage materials for waste gas treatment RTO furnaces. It can solve the problems of small back pressure specific surface area, difficult cleaning, low labor intensity, etc., and achieve reduced production costs, uniform air flow distribution, and easy replacement. Convenient and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

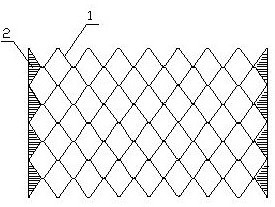

[0018] Example 1, in figure 1 and figure 2 Among them, a large-scale integral honeycomb ceramic regenerator consists of several triangular pieces (the top wave angle is preferably 60°, and can also be in the range of 30-120°) ceramic corrugated green sheets 1 are used according to peak-to-peak and valley-to-valley After the adhesive is superimposed, it is dried, cut and fired, and then on both sides ( figure 1 Fill the blank or similar blanks in the space formed by the corrugated stretching direction, and form a closed layer 2 on both sides to keep the two sides flat and smooth. figure 2 A cross-shaped decompression groove 3 is formed on one end of the shown front and rear ends), so that four protrusions 4 are formed on the four outer corners of the end, and the length and width of the protrusions are four times the length and width of the corresponding sides. One-fifth to one-fifth. In this way, the mechanical strength of the honeycomb body can be further improved, and t...

Embodiment 2

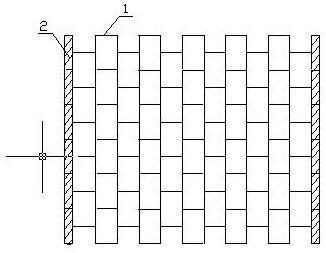

[0039] Example 2, image 3 As shown, a large-scale monolithic honeycomb ceramic regenerator consists of several square (top wave angles of 90°) ceramic corrugated blanks 1 that are stacked peak-to-peak and valley-to-valley with an adhesive, dried, cut, and then fired. made, then on both sides ( image 3 Fill the blank or similar blank in the space formed by the corrugated extension direction, form a closed layer 2 on both sides, keep the two sides flat and smooth, and form a cross on one end of the front and rear ends of the honeycomb ceramic regenerator Decompression groove, and make with following method steps:

[0040] a, with the mixture 40wt% of the mixture of 60 parts of bentonite and 40 parts of ball clay and 30 parts of feldspar, 20 parts of burnt bauxite and 20 parts of burnt talc 40% and the mixture of 50 parts of marble and 30 parts of fluorite 20 % mixed with an appropriate amount of water, aged and coarsely refined into billets, and when the molding water conten...

Embodiment 3

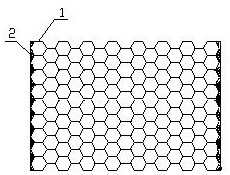

[0045] Example 3, such as Figure 4 As shown, a large-scale monolithic honeycomb ceramic regenerator is made of several regular hexagons (the top wave angle is 120° or 30°), and the honeycomb ceramic regenerator is made by referring to the method steps described in Example 1 and Example 2. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com