A two-layer or multi-layer polymer electrolyte and a battery

An electrolyte and polymer technology, applied in the field of double-layer polymer electrolyte, can solve the problems of reducing battery energy density and cycle performance, difficulty reaching 300Wh/kg, and violating solid-state batteries, etc., to assist lithium ion transport and avoid reaction loss , Promote the effect of lithium salt dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The double-layer electrolyte structure provided by this embodiment is as figure 1 shown. In this embodiment, there is a double-layer electrolyte composed of two layers of polymer electrolytes between the positive electrode and the negative electrode, wherein the positive electrode is lithium cobaltate (LiCoO 2 , LCO), the negative electrode is lithium metal. The first layer of polymer electrolyte is a solid electrolyte that is electrochemically stable to high voltage, and it is in contact with the positive electrode. The polymer electrolyte used is poly(N-methyl-malonic amide (Poly(N-methyl-malonic amide, PMA); the second polymer electrolyte layer is a solid electrolyte that is electrochemically stable at low voltage, which is in contact with the negative electrode, and the polymer electrolyte used is polyethylene oxide (PEO) containing lithium salt.

[0053] figure 1 A schematic diagram of the double-layer electrolyte structure.

[0054] In conventional liquid Li-i...

Embodiment 2

[0059] Performance Test of Double Layer Solid Electrolyte Membrane

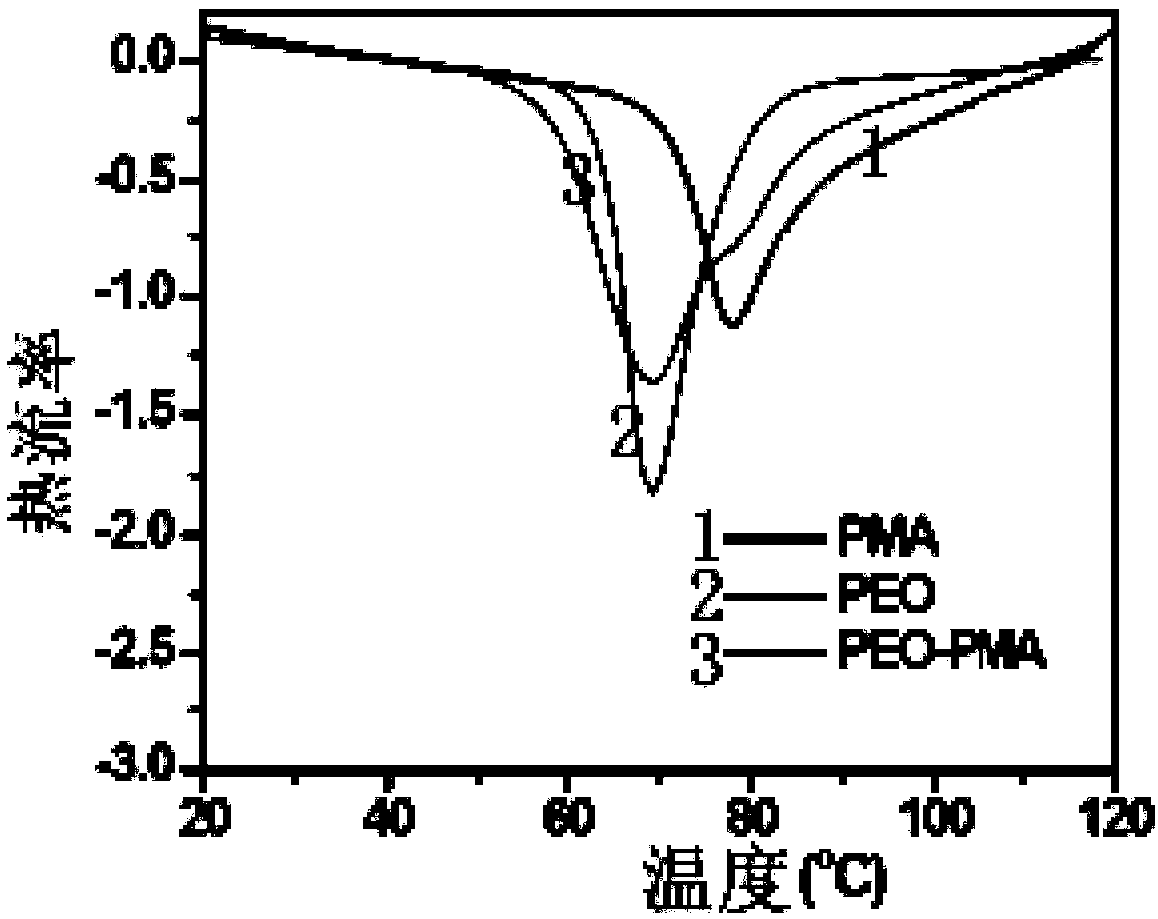

[0060] Differential scanning calorimeter (DSC) was used to test DLPSE, and the two endothermic peaks obtained in the range of 65-85 °C corresponded to the melting points of the PEO layer and the PMA layer (such as figure 2 shown).

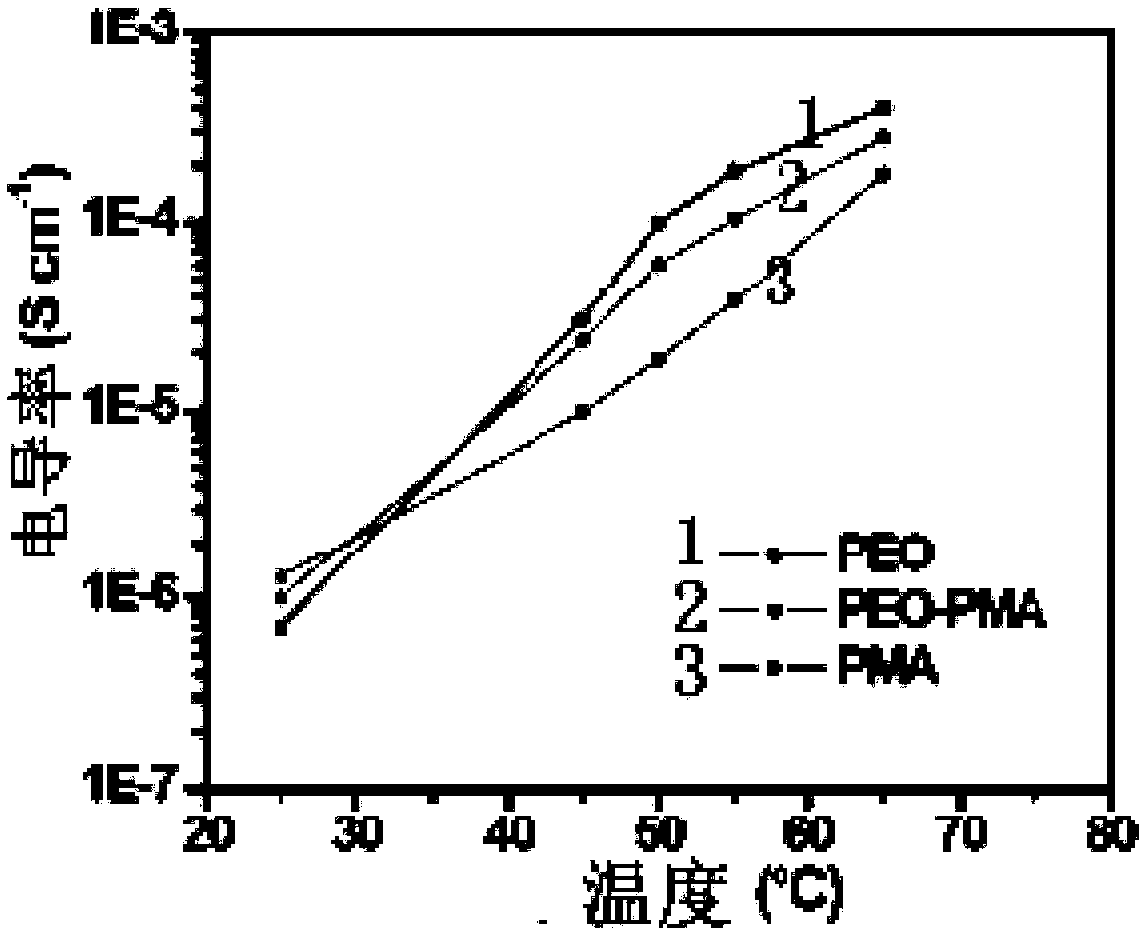

[0061] figure 2 Show the DSC curve graph of PEO, PMA and PEO / PMA three kinds of polymers, image 3 The ion conductivities of PEO, PMA and PEO / PMA three polymers at different temperatures are shown.

[0062] image 3 The ionic conductivities of PEO-Li thin films, PMA-Li thin films and DLPSE at different temperatures (25-65°C) are shown. We can notice that the ionic conductivity of DLPSE in the high temperature region (50–65°C) is between that of PEO-Li and PMA-Li, which indicates that due to the good adhesion between the polymers, PEO-Li and PMA-Li The interface resistance is sufficiently low. Such as image 3 As shown, the conductivity of the dry PMA-Li film at 65 °C is a...

Embodiment 3

[0066] Performance testing of all-solid-state lithium-ion batteries

[0067] To evaluate the electrochemical performance of double-layer electrolytes for practical batteries, we assembled the Li / DLPSE / LiCoO 2 Battery.

[0068] Figure 8 Li / DLPSE / LiCoO 2 The voltage curve of the battery in the first 5 weeks and 100 weeks, the voltage test range is 2.5 ~ 4.2V vs Li / Li + , with a current density of 0.2C (100μA cm -2 ), we can observe that LiCoO 2 The characteristic charge-discharge curves; moreover, the discharge capacity gradually increased in the first 5 weeks due to the electrode infiltration.

[0069] Figure 9 It shows that when the current density is 0.2C, the capacity can be maintained at 108.5mAh g after 100 charge-discharge cycles –1 , up to the highest discharge capacity (119mAh g –1 ), demonstrating the electrochemical stability in charge-discharge cycles.

[0070] Figure 10 It shows that when the current density is 0.1C, 0.2C and 0.5C, the battery capacity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com