Texturing device and method for polycrystalline silicon wafer

A technology of polycrystalline silicon wafers and silicon wafers, which is applied in chemical instruments and methods, crystal growth, and final product manufacturing, etc., can solve the problems of high color difference, unfavorable uniform reaction of liquid medicine in texturing tank, and insufficient liquid medicine circulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

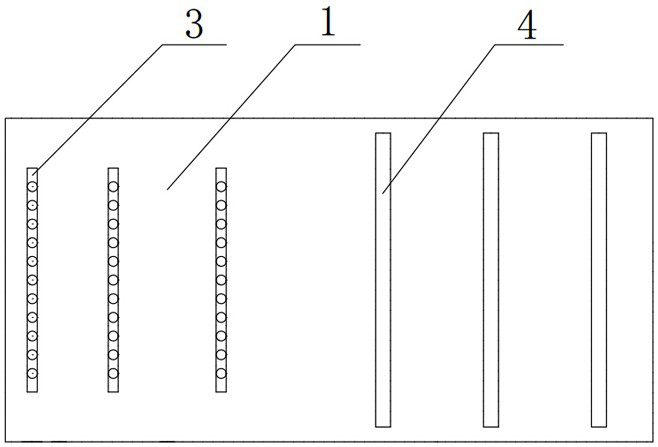

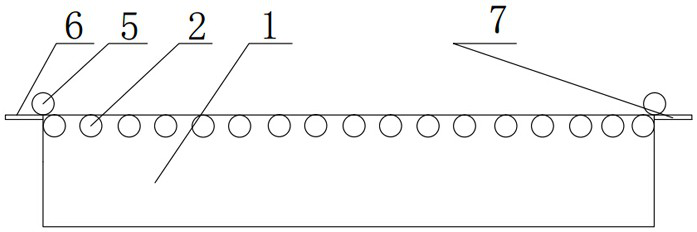

[0031] Specific embodiment one, a polycrystalline silicon wafer texturing device comprises a texturing tank 1, three return pipes 3 are provided at the front half of the bottom of the texturing tank 1, and three liquid inlet pipes 4 are provided at the rear half of the bottom of the texturing tank 1, wherein The liquid inlet pipe 4 is provided with a control valve, and also includes a controller, the control valve is electrically connected to the controller, the return pipe 3 is provided with a return hole, and multiple sets of moving rollers 2 are arranged in the texturing tank 1, and the moving rollers 2. It is divided into upper and lower groups, and the silicon wafers are set in the middle. The silicon wafers are driven to move horizontally in the texturing tank 1 through the upper and lower two groups of moving rollers 2, and liquid blocking wheels 5 are also arranged at both ends of the texturing tank 1. Both ends of the cashmere tank 1 are provided with a first weight de...

specific Embodiment 2

[0033] Specific embodiment two, the main difference with specific embodiment one is that only two return pipes 3 are provided at the front of the cashmere tank 1, and four liquid inlet pipes 4 are provided at the rear, and the liquid inlet flow rate of the liquid inlet pipes 4 is adjusted is 30L / min, and the return hole of the return pipe 3 is a 1 / 3 opening, and the liquid level of the silicon wafer is preferably set to 15-25mm, so that when the liquid level detected by the liquid level detection module is within this range, no It needs to be adjusted. When the liquid level detection module detects that the liquid level is less than 15mm, it is judged that the liquid medicine is too little at this time, and the liquid medicine flow rate of the liquid inlet pipe 4 needs to be increased. At this time, the control valve on the liquid inlet pipe 4 can be adjusted to To increase the flow of liquid medicine, you can also open the previously closed liquid inlet pipe 4 to increase the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com