Method of evaluating hole sealing quality of anodic oxide film

An anodic oxidation film and anodic oxidation technology, applied in the direction of removing certain components and weighing, can solve the problems of poor correlation of phosphoric chromic acid method, shorten the test soaking time, reduce the amount of corrosion, etc., and achieve the effect of good correlation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

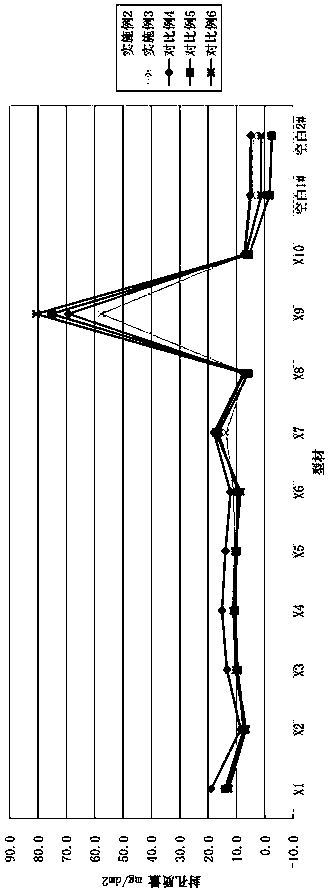

[0051] This embodiment provides a method for evaluating the quality of anodized film sealing. The profiles evaluated in this embodiment include: X1, X2, X3, X4, X5, X6, X7, X8, X9, X10, and also include Anodized (including sealing) profile blank 1# and blank 2#, the concentration of magnesium sulfate used when preparing the magnesium phosphate solution is 20g / L, and the evaluation method is realized by the following steps:

[0052] Step 1: Measurement of the anodized area of the sample, measure the size of the sample with a vernier caliper, and calculate the anodized area A of the sample (retain 2 decimal places).

[0053] Step 2: Degreasing. At room temperature, scrub and degrease the sample in absolute ethanol.

[0054] Step 3: Drying, air-dry the sample at room temperature (pre-drying) for 5 minutes, then place it upright in a preheated drying oven at 60°C for 15 minutes, and then place the sample on top of the silica gel in a sealed desiccator to cool for 30 minutes.

...

Embodiment 2

[0075] The present embodiment provides a kind of evaluation method of anodized film sealing quality, and the sample evaluated in the present embodiment is identical with embodiment 1, and the concentration of the magnesium sulfate that adopts when preparing magnesium phosphate solution is 20g / L, evaluates The method is implemented through the following steps:

[0076] Steps 1 to 4 follow the method in Example 1.

[0077] Step 5: Phosphomagnesic acid method, immerse the sample upright in the pre-heated magnesium phosphate solution for 15 minutes, and the test temperature is 38°C; take the sample out of the test solution, wash it with tap water first, and then with deionized water; finally Weigh the sample mass immediately after drying according to step 3 (m 2 ), accurate to 0.1 mg; the result calculation is according to the calculation method in Example 1.

Embodiment 3

[0079] The present embodiment provides a kind of evaluation method of anodized film sealing quality, and the sample evaluated in the present embodiment is identical with embodiment 1, and the concentration of the magnesium sulfate that adopts when preparing phosphomagnesic acid solution is 50g / L, evaluates The method is implemented through the following steps:

[0080] Steps 1 to 4 follow the method in Example 1.

[0081] Step 5: Phosphomagnesic acid method, immerse the sample upright in the preheated magnesium phosphatic acid solution for 15 minutes, and the test temperature is 38°C; take the sample out of the test solution, wash it with tap water first, and then with deionized water; Finally weigh the sample mass (m) immediately after drying according to step 3 2 ), accurate to 0.1 mg; the result calculation is according to the calculation method in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com