A method for purifying kitchen fumes

A technology for oil fume purification and oil fume, which is applied in the direction of oil fume removal, heating methods, household stoves/stoves, etc., and can solve problems that affect the appearance of the city and the health of surrounding residents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

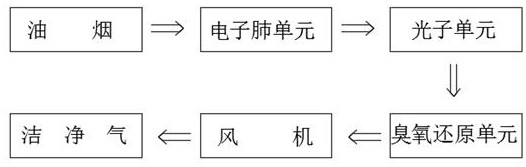

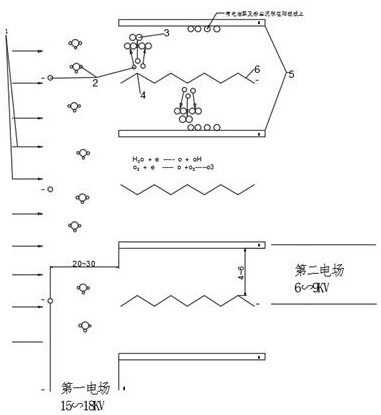

[0083] Such as Figure 7 As shown, before the oil fume 1 enters the electronic lung unit 12, the exhaust gas is inhaled by the air inlet 11, and the oil fume 1 particles in the exhaust gas are filtered, and then enter the first electric field and the second electric field of the electronic lung unit 12, and the partially purified exhaust gas Then enter the photon unit 14 to realize targeted exhaust gas treatment. In order to reduce secondary pollution, an ozone reduction reaction is performed on the ozone generated in the electronic lung unit 12 and the photon unit 14, and the clean air passing through the ozone reduction unit is sent out by a fan. In the purification process, a water eliminator 13 is also added to filter the water vapor in the exhaust gas. The water eliminator 13 can also be changed to an electronic lung unit 12 or a photon unit 14 as required. For the gas that has passed through the above process, when the exhaust gas does not When the requirements are met,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com