Medical titanium alloy bar with anti-bacterial function and osteoinductive activity

A titanium alloy, osteoinductive technology, applied in metal material coating technology, medical science, ion implantation plating, etc., can solve the problem of not promoting blood coagulation and wound healing, not promoting blood coagulation and wound healing, not solving wear resistance problems such as biocompatibility and osteoinductive activity, promoting blood coagulation and wound healing, and improving thermodynamic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

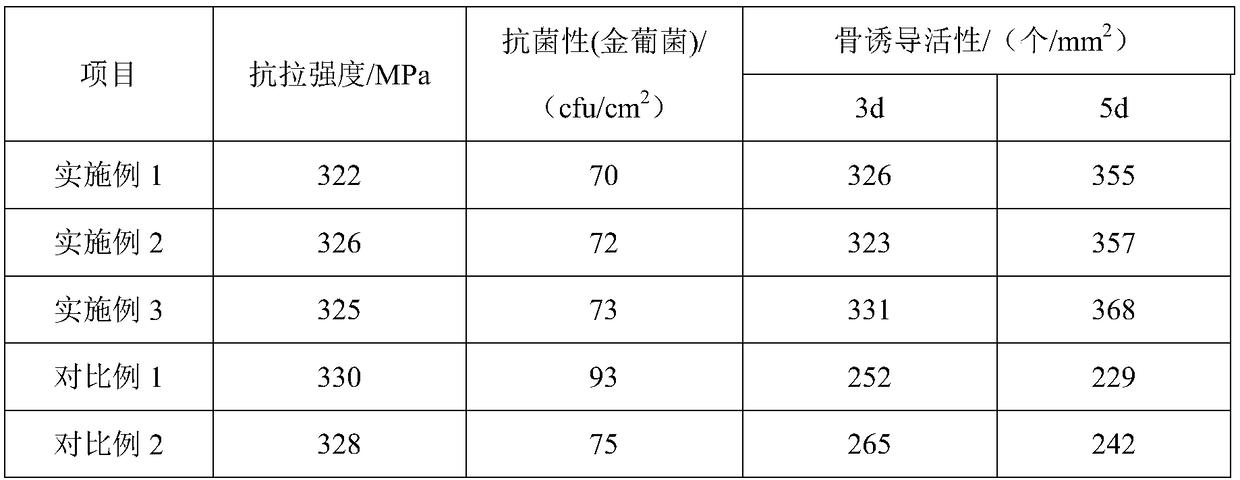

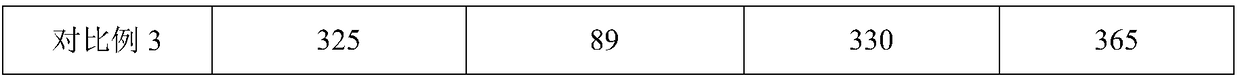

Examples

Embodiment 1

[0026] 1) Preparation of titanium alloy ingot: the chemical composition of the titanium alloy ingot is calculated by mass percentage: W 2.0%, Zn 4.0%, Fe 2%, Mo0.7%, Sr 0.5%, Se 1.2%, Sn 0.6%, the balance is Ti;

[0027] Put the prepared raw materials into the non-consumable electrode water-cooled copper crucible electric arc furnace, and evacuate the furnace to 8.5×10 - 4 Pa, the argon gas with a purity of 99.99% was introduced for 3 times of repeated gas scrubbing, and then smelted with electricity (temperature 1800°C, holding time 60 minutes) and cast into an ingot, and the ingot was turned over 180° and remelted 5 times to ensure the uniformity of the composition;

[0028] 2) Deformation processing: Coat a layer of hexagonal boron nitride on the surface of the ingot to prevent oxidation and increase lubrication during high-temperature processing, keep the ingot coated with hexagonal boron nitride at 850-1150°C for 2.5h, and then carry out free forging , the final forging...

Embodiment 2

[0039] 1) Preparation of titanium alloy ingot: the chemical composition of the titanium alloy ingot is calculated by mass percentage: W 2.2%, Zn 4.5%, Fe2.2%, Mo0.8%, Sr 0.6%, Se 1.5%, Sn 0.7%, the balance is Ti;

[0040] Put the prepared raw materials into the non-consumable electrode water-cooled copper crucible electric arc furnace, and evacuate the furnace to 8.5×10 - 4 Pa, the argon gas with a purity of 99.99% was introduced for 3 times of repeated gas scrubbing, and then smelted with electricity (temperature 1800°C, holding time 60 minutes) and cast into an ingot, and the ingot was turned over 180° and remelted 5 times to ensure the uniformity of the composition;

[0041] 2) Deformation processing: Coat a layer of hexagonal boron nitride on the surface of the ingot to prevent oxidation and increase lubrication during high-temperature processing, keep the ingot coated with hexagonal boron nitride at 850-1150°C for 2.5h, and then carry out free forging , the final forgin...

Embodiment 3

[0052] 1) Preparation of titanium alloy ingot: the chemical composition of the titanium alloy ingot by mass percentage is: W 3.2%, Zn6%, Fe 4.8%, Mo 1.1%, Sr 0.8%, Se 0.9%, Sn 0.8% , the balance is Ti;

[0053] Put the prepared raw materials into the non-consumable electrode water-cooled copper crucible electric arc furnace, and evacuate the furnace to 8.5×10 - 4 Pa, the argon gas with a purity of 99.99% was introduced for 3 times of repeated gas scrubbing, and then smelted with electricity (temperature 1800°C, holding time 60 minutes) and cast into an ingot, and the ingot was turned over 180° and remelted 5 times to ensure the uniformity of the composition;

[0054] 2) Deformation processing: Coat a layer of hexagonal boron nitride on the surface of the ingot to prevent oxidation and increase lubrication during high-temperature processing, keep the ingot coated with hexagonal boron nitride at 850-1150°C for 2.5h, and then carry out free forging , the final forging temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com