Method for preparing brick material of wall body with sludge compound mineralized refuse

A technology for mineralizing garbage and sludge, which is applied in chemical instruments and methods, dehydration/drying/concentrated sludge treatment, solid separation, etc., can solve the difficulty of industrialization and water content of molding wall bricks prepared by blending sludge The floating range is not large, which affects the strength of the sintered product, and achieves the effects of good homogenization, light weight and good heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The preparation method of the wall brick of the present embodiment comprises the following steps:

[0070] Step 1. Sorting and processing the mineralized garbage to obtain mineralized garbage powder with a particle size not greater than 3mm, and the water content of the mineralized garbage powder is not greater than 10wt%;

[0071] Step 2, processing the sludge to obtain dried sludge powder;

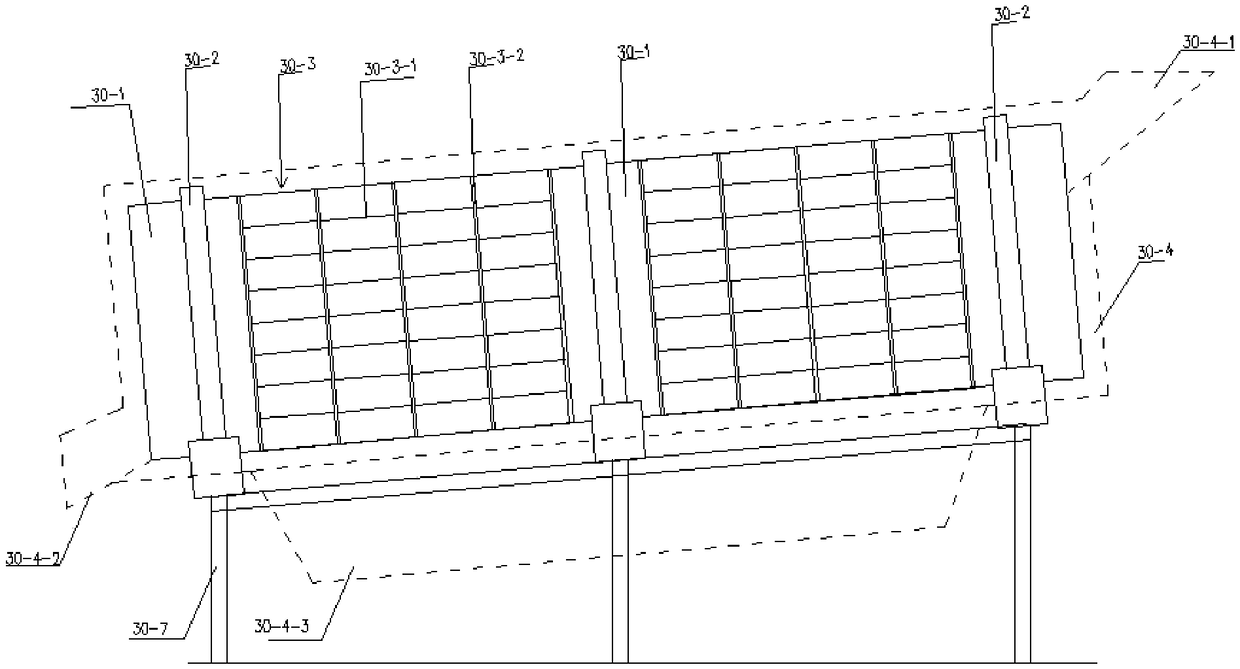

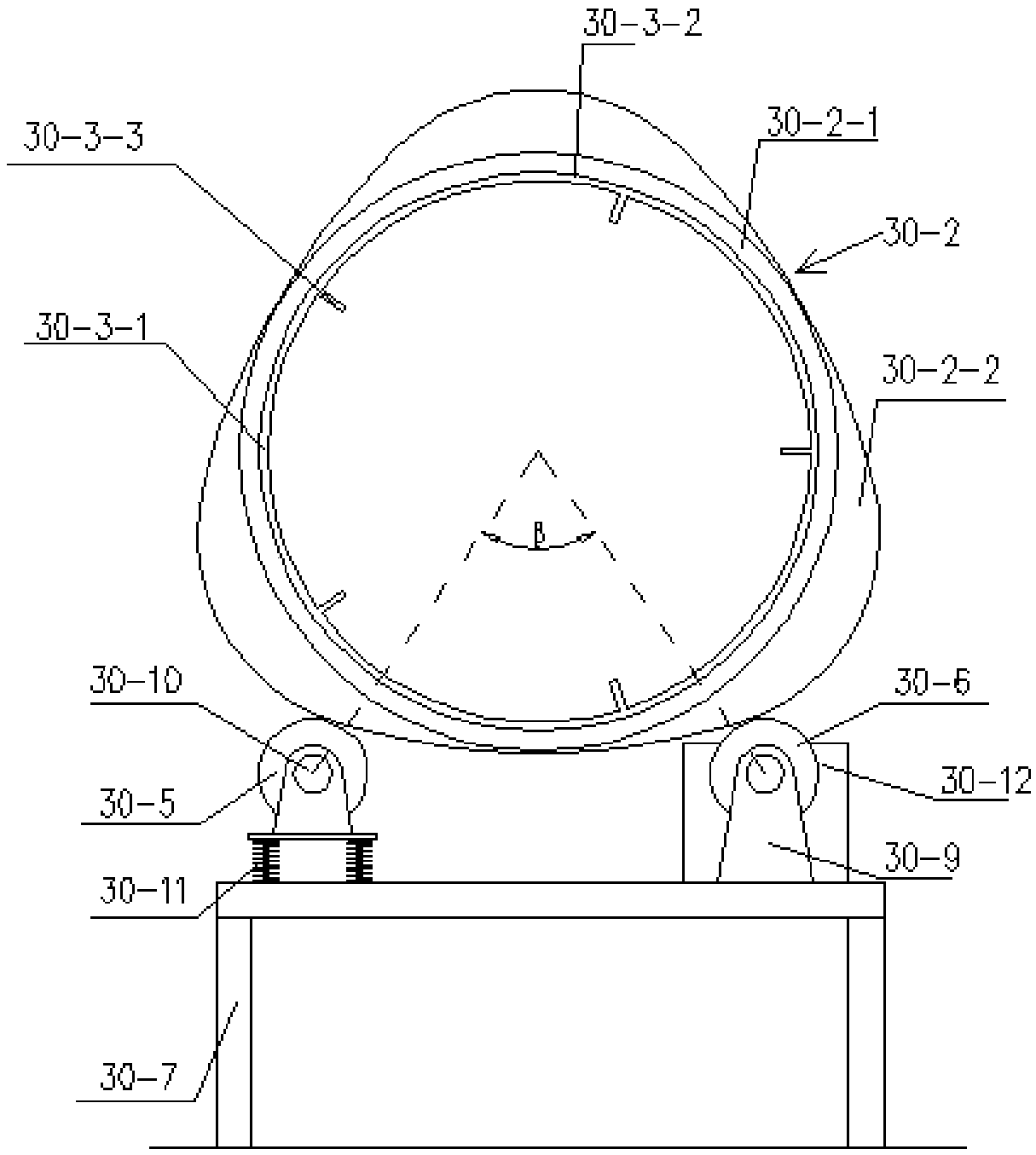

[0072] Step 3. Mix the mineralized garbage powder obtained in step 1 and the dried sludge powder obtained in step 2, put them into a horizontal homogenizer for homogenization, and then add ingredients to the homogenized material to obtain a mixed The mixed material is sent into the mixer and added with water for the first stirring to obtain a primary mixed material; the mixed material is shale and coal gangue; the mass content of mineralized garbage powder in the mixed material is 30% , the mass content of the sludge material is 30%, and the mass content of the blending ingredien...

Embodiment 2

[0108] The preparation method of the wall brick of the present embodiment comprises the following steps:

[0109] Step 1. Sorting and processing the mineralized garbage to obtain mineralized garbage powder with a particle size not greater than 3 mm, and the water content of the mineralized garbage powder is 9 wt %;

[0110] Step 2, processing the sludge to obtain dried sludge powder;

[0111] Step 3. Mix the mineralized garbage powder obtained in step 1 and the dried sludge powder obtained in step 2, put them into a horizontal homogenizer for homogenization, and then add ingredients to the homogenized material to obtain a mixed material, and then the mixture is sent into the mixer to add water for the first time to stir, to obtain a primary mixture; the mixed material is sandstone; the mass content of mineralized garbage powder in the mixture is 40%, and the sludge The mass content of the material is 20%, and the mass content of the blending ingredients is 40%; the water cont...

Embodiment 3

[0132] The preparation method of the wall brick of the present embodiment comprises the following steps:

[0133] Step 1. Sorting and processing the mineralized garbage to obtain mineralized garbage powder with a particle size not greater than 3 mm, and the water content of the mineralized garbage powder is 5 wt %;

[0134] Step 2, processing the sludge to obtain dried sludge powder;

[0135] Step 3. Mix the mineralized garbage powder obtained in step 1 and the dried sludge powder obtained in step 2, put them into a horizontal homogenizer for homogenization, and then add ingredients to the homogenized material to obtain a mixed material, and then the mixture is sent into the mixer to add water and stir for the first time to obtain a primary mixture; the mixed ingredients are shale, coal gangue and sandstone; the mass content of mineralized garbage powder in the mixture is 35%, the mass content of the sludge material is 25%, and the mass content of the blending ingredients (th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com