Manufacture method of tunnel cantilever base capable of improving anti-fatigue performance

A production method and anti-fatigue technology, applied in the direction of overhead wire, coating, metal material coating technology, etc., can solve the problems of insufficient wear resistance, low fatigue resistance, and increased friction at hinges, so as to avoid ineffective Effects of processing, improvement of fatigue life, and good surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

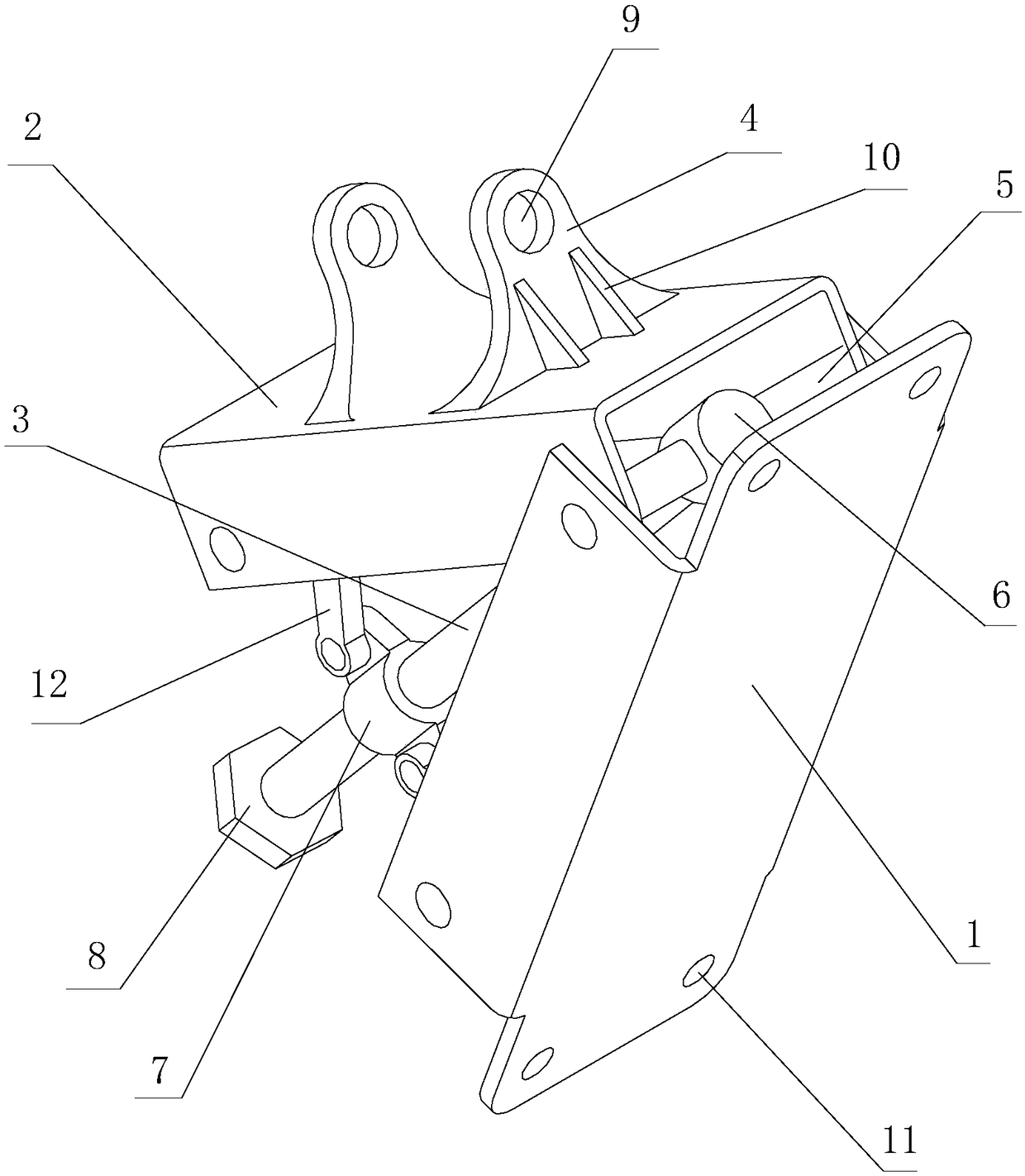

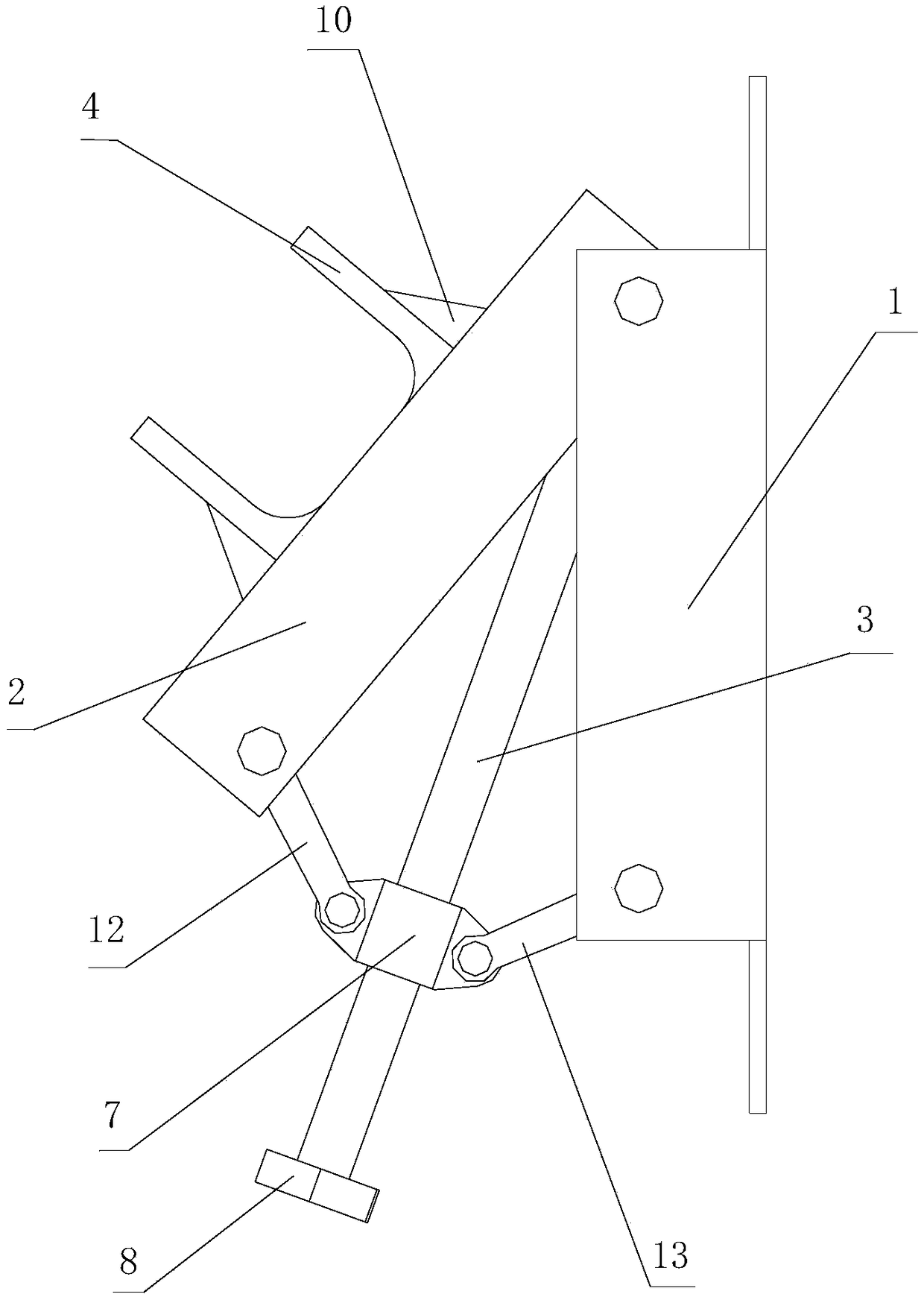

[0025] A method for making a tunnel arm base that improves fatigue resistance. The tunnel arm base includes a base, an adjustment seat, and a rotating shaft. At least one of the base, the adjustment seat, and the rotating shaft is processed according to the following steps:

[0026] S1. Raw material equipment: choose low carbon steel Q235 as raw material, cut the material according to the size required by the parts, and remove rust;

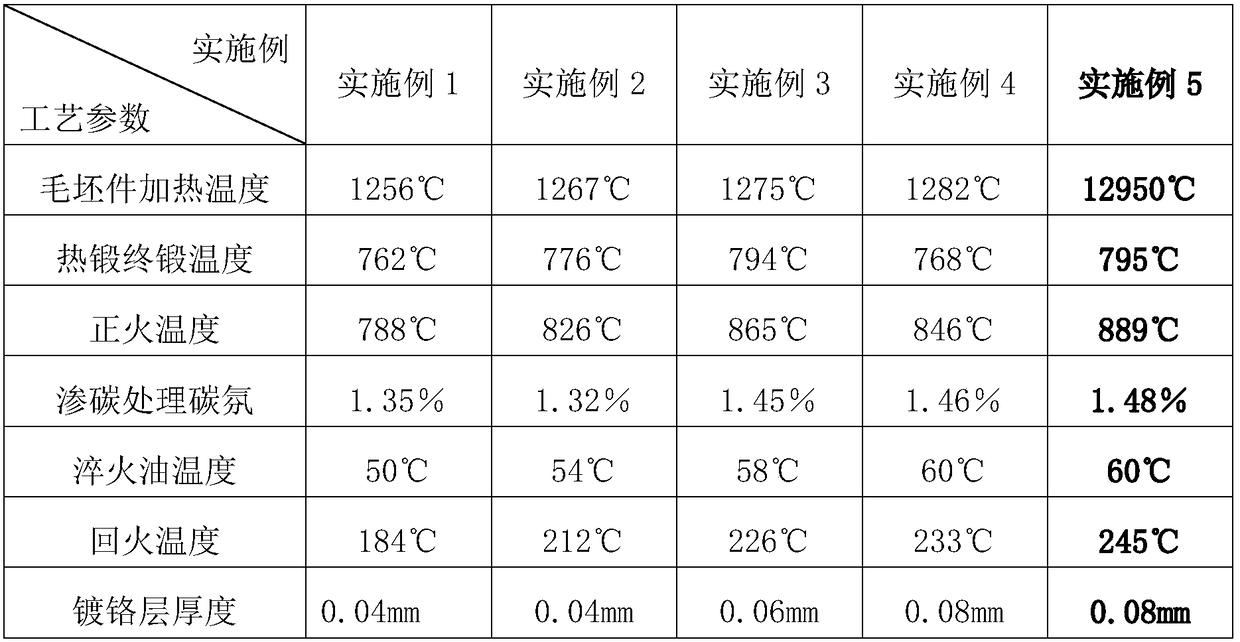

[0027] S2, heating the blank to 1250°C-1300°C;

[0028] S3. Putting the blank processed in step S2 into a corresponding forging die for hot forging, the final forging temperature is 750°C-800°C;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com