High-strength alloy gray cast iron valve body manufacturing technology

A high-strength alloy and manufacturing process technology, applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problem of cracks in the ribs of large-diameter valves, unstable gray iron flake graphite, and core strength. Difficult to meet the requirements and other issues, to achieve the effect of enhanced deformation resistance, excellent comprehensive performance, and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

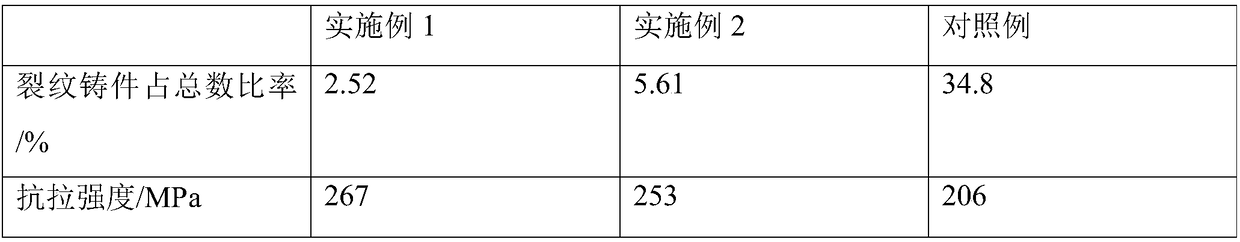

Examples

Embodiment 1

[0027] A manufacturing process for a high-strength alloy gray cast iron valve body provided in this embodiment includes the following steps:

[0028] S1. The casting is prepared by the wet dry core molding process. The wall thickness of the casting is 12mm, and the thickness of the reinforcing rib is 12mm. Among them, the molding sand is yellow sand, the wet air permeability is greater than 100, the wet compressive strength is 45KPa, and the molten iron pouring temperature is controlled at 1320 ℃, the casting time is 52min, the chemical composition and mass percentage of molten iron are: C: 3.28%, Si: 1.66%, Mn: 0.76%, P: 0.027%, S: 0.035%, the balance is iron and unavoidable impurities;

[0029] S2, the rare earth alloy is crushed, fully preheated, and then placed at the bottom of the ladle, wherein the mass fraction of the rare earth alloy is 0.2%, and the chemical composition and mass percentage are Ce: 10%, Mo: 5%, Si: 43% , the balance is iron;

[0030] S3. After the ca...

Embodiment 2

[0033] A manufacturing process for a high-strength alloy gray cast iron valve body provided in this embodiment includes the following steps:

[0034] S1. The casting is prepared by the wet dry core molding process. The wall thickness of the casting is 12mm, and the thickness of the reinforcing rib is 12mm. Among them, the molding sand is yellow sand, the wet air permeability is greater than 100, the wet compressive strength is 50KPa, and the molten iron pouring temperature is controlled at 1335 ℃, the casting time is 48min, the chemical composition and mass percentage of molten iron are: C: 3.34%, Si: 1.76%, Mn: 0.77%, P: 0.029%, S: 0.028%, the balance is iron and unavoidable impurities;

[0035] S2, the rare earth alloy is crushed, fully preheated, and then placed at the bottom of the ladle, wherein the mass fraction of the rare earth alloy is 0.2%, and the chemical composition and mass percentage are Ce: 10%, Mo: 5%, Si: 43% , the balance is iron;

[0036] S3. After the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com