Preparation method for BiOBr nanorod, and applications

A technology of nanorods and reactions, applied in chemical instruments and methods, catalyst activation/preparation, inorganic chemistry, etc., can solve problems such as unfavorable sewage treatment, increased production costs, environmental threats, etc., and achieve good effects, good crystallinity, The effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

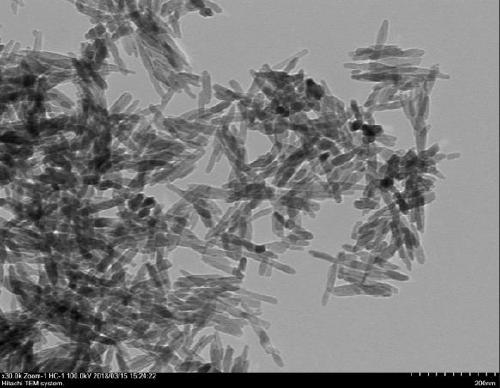

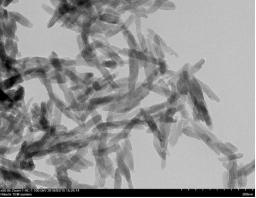

Image

Examples

Embodiment 1

[0022] Weigh bismuth nitrate pentahydrate and sodium bromide at a molar ratio of 1:1.1, grind the mixture of the two in an agate mortar for 5 minutes, then transfer the ground mixture to a planetary ball mill for high-speed grinding reaction, wherein the ball milling speed is 3000rpm, and the ball milling time is 3min; after the ball milling is finished, the intermediate product is taken out from the ball mill tank; it is dispersed in deionized water, and the amount of 2.5mg intermediate product added per milliliter of deionized water is added; after the addition is completed, put Put it into a hydrothermal reaction kettle and react at 100°C for 8 hours. After the reaction, cool down to room temperature naturally, centrifuge, wash with water and alcohol in sequence, and dry at 60°C.

Embodiment 2

[0024] Weigh bismuth nitrate pentahydrate and sodium bromide at a molar ratio of 1:1.3, grind the mixture of the two in an agate mortar for 5 minutes, then transfer the ground mixture to a planetary ball mill for high-speed grinding reaction, wherein the ball milling speed is 3000rpm, and the ball milling time is 3min; after the ball milling is finished, the intermediate product is taken out from the ball mill tank; it is dispersed in deionized water, and the amount of 2.5mg intermediate product added per milliliter of deionized water is added; after the addition is completed, put Put it into a hydrothermal reaction kettle and react at 110°C for 7 hours. After the reaction, cool down to room temperature naturally, centrifuge, wash with water and alcohol in sequence, and dry at 60°C.

Embodiment 3

[0026] Weigh bismuth nitrate pentahydrate and sodium bromide at a molar ratio of 1:1.5, grind the mixture of the two in an agate mortar for 5 minutes, then transfer the ground mixture to a planetary ball mill for high-speed grinding reaction, wherein the ball milling speed is 4000rpm, and the ball milling time is 2.5min; after the ball milling is finished, the intermediate product is taken out from the ball mill tank; it is dispersed in deionized water, and the amount of 2.5mg of the intermediate product is added per milliliter of deionized water; after the addition is completed, Put it into a hydrothermal reaction kettle and react at 120°C for 7 hours. After the reaction, cool down to room temperature naturally, centrifuge, wash with water and alcohol in sequence, and dry at 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com