A preparation method of spinel spherical high-entropy oxide material for negative electrode material of lithium ion battery

A technology of lithium ion battery and negative electrode material, which is applied in the field of 3O4 high entropy oxide material and its preparation, and achieves the effects of short time, high efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

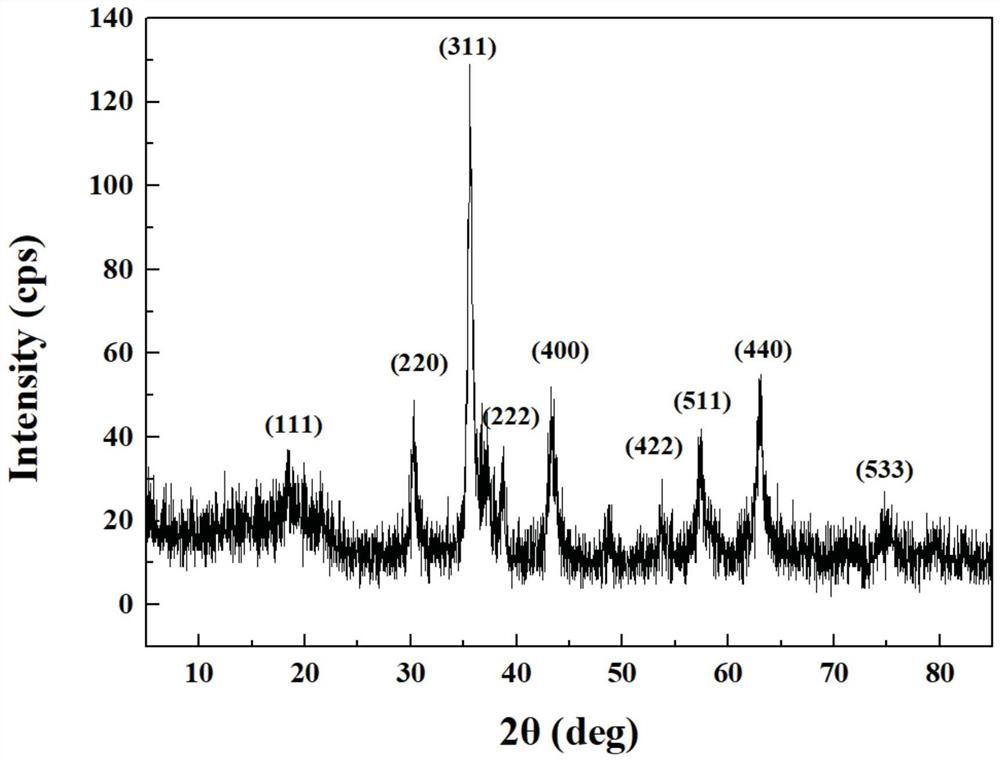

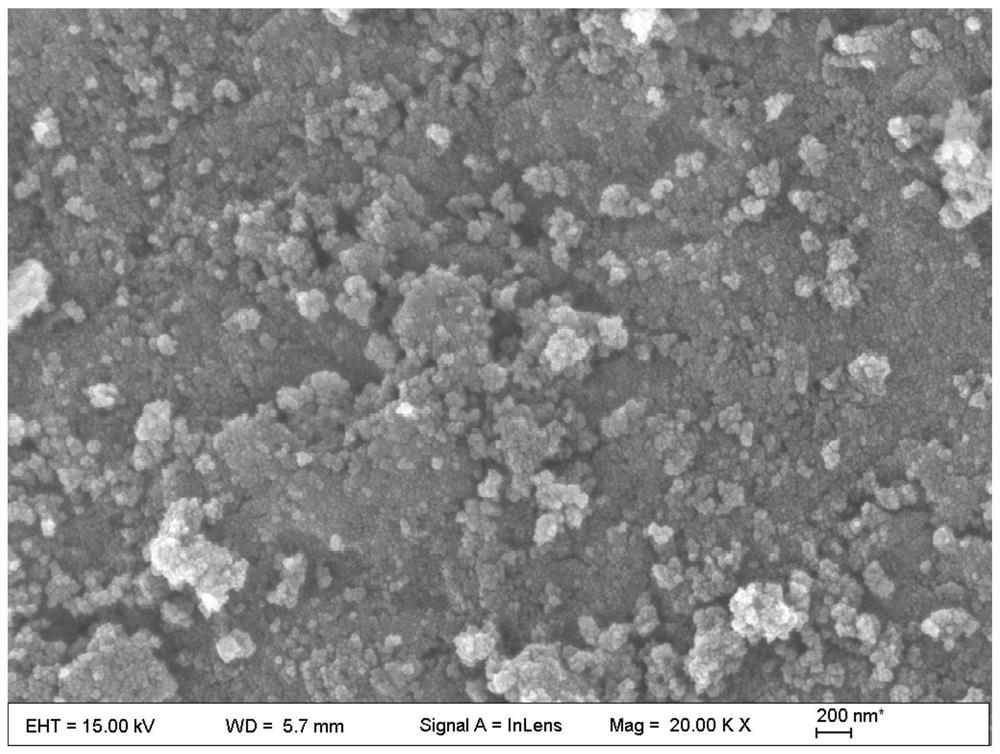

[0021] Weigh an equimolar amount of 11.90g of CoCl 2 ·6H 2 O, 13.32g of CrCl 3 ·6H 2 O, 7.95 g of CuCl 2 2H 2 O, 13.52 g of FeCl 3 ·6H 2 O and 11.89 g of NiCl 2 ·6H 2 O Five kinds of metal salts are dissolved in 250mL distilled water and used as an oxidation solution after mixing; weigh 20.4g of NaOH and dissolve in 1700 mLH 2 After adding 26.35g of sodium thiosulfate and 0.14g of surfactant polyvinylpyrrolidone in O, mix well and use it as a reducing solution; drop the above oxidation solution into the reducing solution at a speed of 15mL / min, and Magnetic stirring at a reaction temperature of ℃, continued stirring for 30 minutes after the dropwise addition, aging for 30 minutes, centrifuged and calcined in a muffle furnace at 300 ℃ to obtain the final product. XRD spectrum ( figure 1 ) shows that the prepared (CoCrCuFeNi) 3 o 4 The high-entropy oxide material is a spinel structure, and the SEM picture ( figure 2 ) shows that the prepared (CoCrCuFeNi) 3 o 4 Th...

Embodiment 2

[0023] Weigh 43.66g of Co(NO 3 ) 2 ·6H 2 O, 60.18g of Cr(NO 3 ) 3 9H 2 O, 36.24g of Cu(NO 3 ) 2 ·3H 2 O, 60.6g of Fe(NO 3 ) 3 9H 2 O and 43.62g of Ni(NO 3 ) 2 ·6H 2 O five kinds of metal salts, dissolve them in 250mL distilled water, mix well and use as oxidation solution; weigh 75g of NaOH and dissolve in 2500mLH 2 After adding 28.37g of sodium borohydride and 1.78g of surfactant polyethylene glycol, mix well and use it as a reducing solution; drop the above oxidation solution into the reducing solution at a speed of 30mL / min, and in 20 Magnetic stirring at the reaction temperature of ℃, continued stirring for 40 minutes after the dropwise addition and aging for 60 minutes, and calcined in a muffle furnace at 500 ℃ after centrifugation to obtain a spherical (CoCrCuFeNi) with a spinel structure and an average particle size of 110 nm. 3 o 4 High entropy oxide materials.

Embodiment 3

[0025] Weigh an equimolar amount of 11.24g of CoSO 4 ·7H 2 O, 6.60g of Cr(OH)SO 4 , 9.99g of CuSO 4 ·5H 2 O, 11.12g of FeSO 4 ·7H 2 O and 10.51 g NiSO 4 ·6H 2O five kinds of metal salts, dissolve them in 200mL distilled water, mix well and use as an oxidation solution; weigh 16g of NaOH and dissolve in 320 mLH 2 After adding 6.05g of sodium borohydride and 1.03g of surfactant sorbitol, mix well and use it as a reducing solution; add the above-mentioned oxidizing solution to the reducing solution dropwise at a speed of 10mL / min, and heat Stir magnetically at the reaction temperature, continue to stir for 60 minutes after the dropwise addition, and age for 40 minutes. After centrifugation, it is calcined in a muffle furnace at 400 ° C to obtain a spherical (CoCrCuFeNi) with a spinel structure and an average particle size of 75 nm. 3 o 4 High entropy oxide materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com