A Polyoxide Co-doped Thermal Barrier Coating Resistant to Molten Glass Corrosion

A technology of thermal barrier coatings and polyoxides, which is applied in coatings, fusion spraying, metal material coating processes, etc., can solve the problems of coating failure and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

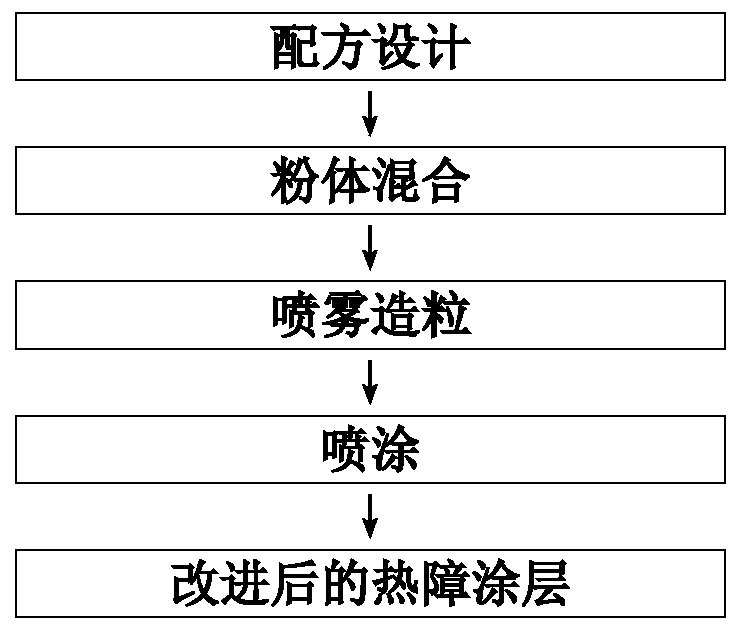

[0045] according to figure 1 The flow chart shown prepares the ceramic layer of the polyoxide co-doped thermal barrier coating of the present invention:

[0046] According to mass percentage, Y 2 o 3 6.8%, ZrO 2 73%, Al 2 o 3 16.9%, TiO 2 3.3%; the specific steps are as follows:

[0047] Step 1. Powder mixing: Weigh the ingredients according to the formula designed in step 1, grind them thoroughly with an agate mortar, and mix evenly to obtain a uniformly mixed mixed powder 1;

[0048] Step 2. Spray granulation: use the mixed powder 1 uniformly mixed in step 1 to obtain the powder 2 for plasma spraying with a particle size between 20-40 μm by spray granulation;

[0049] Step 3. Spraying: The temperature at the center of the plasma arc is 2 x 10 4 In the case of K and He protection, the powder 2 prepared in step 2 is plasma sprayed at a spraying speed of 1 Mach, so that the powder 2 is deposited on the surface of the bonding layer NiCrAlY, and the layers are stacked...

Embodiment 2

[0052] according to figure 1 The flow chart shown prepares the ceramic layer of the polyoxide co-doped thermal barrier coating of the present invention:

[0053] According to mass percentage, Y 2 o 3 5.1%, ZrO 2 59.1%, Al 2 o 3 13.0%, TiO 2 3.25%; Nd 2 o 3 9.0%; Yb 2 o 3 10.55%; the specific steps are as follows:

[0054] Step 1. Powder mixing: Weigh the ingredients according to the formula designed in step 1, grind them thoroughly with an agate mortar, and mix evenly to obtain a uniformly mixed mixed powder 1;

[0055] Step 2. Spray granulation: use the mixed powder 1 uniformly mixed in step 1 to obtain the powder 2 for plasma spraying with a particle size between 20-40 μm by spray granulation;

[0056] Step 3. Spraying: The temperature at the center of the plasma arc is 2 x 10 4 In the case of K and He protection, the powder 2 prepared in step 2 is plasma sprayed at a spraying speed of 1 Mach, so that the powder 2 is deposited on the surface of the bonding l...

Embodiment 3

[0059] according to figure 1 The flow chart shown prepares the polyoxide co-doped thermal barrier coating of the present invention:

[0060] According to mass percentage, Y 2 o 3 6.0%, ZrO 2 65.0%, Al 2 o 3 13.0%, TiO 2 3.3%; Nd 2 o 3 5.0%; Yb 2 o 3 7.7%; the specific steps are as follows:

[0061] Step 1. Powder mixing: Weigh the ingredients according to the formula designed in step 1, grind them thoroughly with an agate mortar, and mix evenly to obtain a uniformly mixed mixed powder 1;

[0062] Step 2. Spray granulation: use the mixed powder 1 uniformly mixed in step 1 to obtain the powder 2 for plasma spraying with a particle size between 20-40 μm by spray granulation;

[0063] Step 3. Spraying: The temperature at the center of the plasma arc is 2 x 10 4 In the case of K and He protection, the powder 2 prepared in step 2 is plasma sprayed at a spraying speed of 1 Mach, so that the powder 2 is deposited on the surface of the bonding layer NiCrAlY, and the la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com