Multiple-oxides codoped molten glass corrosion-resistant thermal barrier coating layer

A technology of thermal barrier coating and polyoxide, which is applied in coating, fusion spraying, metal material coating process, etc., can solve the problems of high cost and coating failure, reduce porosity, improve phase stability, Effect of Improving CMAS Corrosion Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

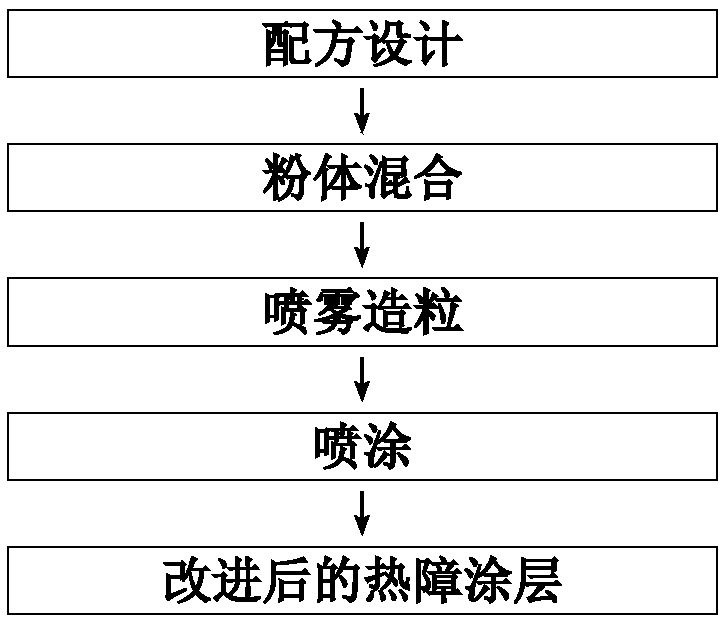

[0045] according to figure 1 The flow chart shown prepares the ceramic layer of the polyoxide co-doped thermal barrier coating of the present invention:

[0046] According to mass percentage, Y 2 o 3 6.8%, ZrO 2 73%, Al 2 o 3 16.9%, TiO 2 3.3%; the specific steps are as follows:

[0047] Step 1. Powder mixing: Weigh the ingredients according to the formula designed in step 1, grind them thoroughly with an agate mortar, and mix evenly to obtain a uniformly mixed mixed powder 1;

[0048] Step 2. Spray granulation: use the mixed powder 1 uniformly mixed in step 1 to obtain the powder 2 for plasma spraying with a particle size between 20-40 μm by spray granulation;

[0049] Step 3. Spraying: The temperature at the center of the plasma arc is 2 x 10 4 In the case of K and He protection, the powder 2 prepared in step 2 is plasma sprayed at a spraying speed of 1 Mach, so that the powder 2 is deposited on the surface of the bonding layer NiCrAlY, and the layers are stacked...

Embodiment 2

[0052] according to figure 1 The flow chart shown prepares the ceramic layer of the polyoxide co-doped thermal barrier coating of the present invention:

[0053] According to mass percentage, Y 2 o 3 5.1%, ZrO 2 59.1%, Al 2 o 3 13.0%, TiO 2 3.25%; Nd 2 o 3 9.0%; Yb 2 o 3 10.55%; the specific steps are as follows:

[0054] Step 1. Powder mixing: Weigh the ingredients according to the formula designed in step 1, grind them thoroughly with an agate mortar, and mix evenly to obtain a uniformly mixed mixed powder 1;

[0055] Step 2. Spray granulation: use the mixed powder 1 uniformly mixed in step 1 to obtain the powder 2 for plasma spraying with a particle size between 20-40 μm by spray granulation;

[0056] Step 3. Spraying: The temperature at the center of the plasma arc is 2 x 10 4 In the case of K and He protection, the powder 2 prepared in step 2 is plasma sprayed at a spraying speed of 1 Mach, so that the powder 2 is deposited on the surface of the bonding l...

Embodiment 3

[0059] according to figure 1 The flow chart shown prepares the polyoxide co-doped thermal barrier coating of the present invention:

[0060] According to mass percentage, Y 2 o 3 6.0%, ZrO 2 65.0%, Al 2 o 3 13.0%, TiO 2 3.3%; Nd 2 o 3 5.0%; Yb 2 o 3 7.7%; the specific steps are as follows:

[0061] Step 1. Powder mixing: Weigh the ingredients according to the formula designed in step 1, grind them thoroughly with an agate mortar, and mix evenly to obtain a uniformly mixed mixed powder 1;

[0062] Step 2. Spray granulation: use the mixed powder 1 uniformly mixed in step 1 to obtain the powder 2 for plasma spraying with a particle size between 20-40 μm by spray granulation;

[0063] Step 3. Spraying: The temperature at the center of the plasma arc is 2 x 10 4 In the case of K and He protection, the powder 2 prepared in step 2 is plasma sprayed at a spraying speed of 1 Mach, so that the powder 2 is deposited on the surface of the bonding layer NiCrAlY, and the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com