Oil-resistant anti-freeze-thawing fireproof door core board

A fire-resistant door core board, anti-freeze-thaw technology, applied in applications, household appliances, ceramic products, etc., can solve problems such as application limitations, insufficient fire resistance, etc., to achieve a wide range of raw materials, high fire resistance, water resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment relates to an oil-resistant freeze-thaw resistant fire door core board and its preparation method. The fire door core board is composed of the following raw materials in parts by weight:

[0057] 42 parts of niobium yttrium tailings powder;

[0058] 16 parts of phosphogypsum powder;

[0059] 20 parts of pyrophyllite powder;

[0060] 6 parts palm leaf fiber;

[0061] 11 parts of pozzolan Portland cement;

[0062] 2 parts of maleic anhydride grafted polypropylene;

[0063] 3 parts of ZK-9 rubber powder;

[0064] Parts of dispersant FT-781:

[0065] 2 parts of compound coupling agent;

[0066] 3 parts of compound foaming agent;

[0067] Composite water repellent 1.5 parts.

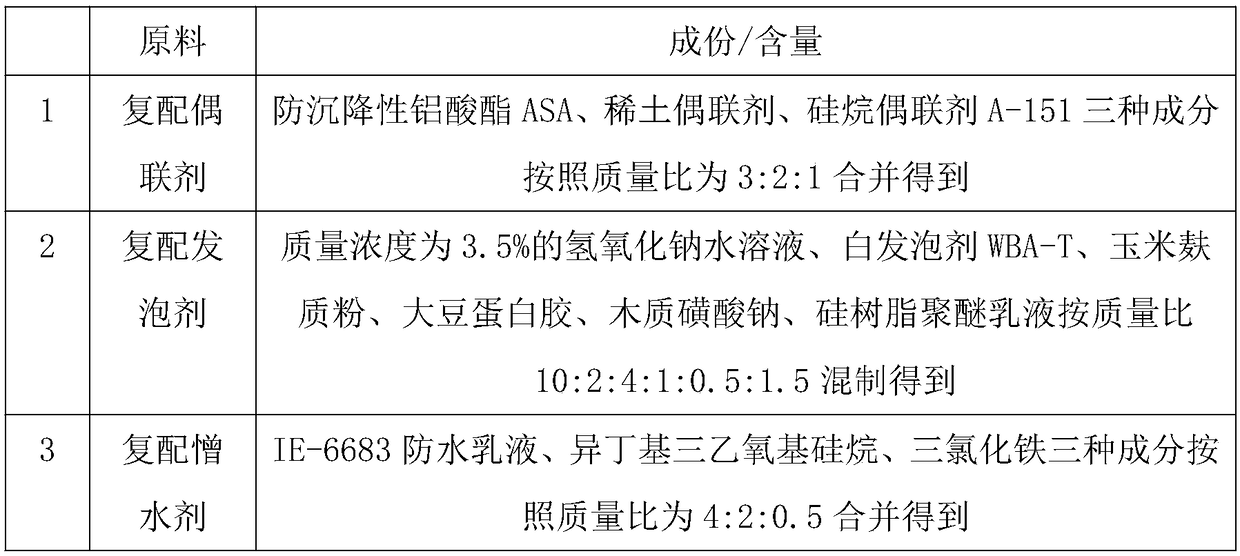

[0068] The selection and preparation of the compound coupling agent, compound foaming agent and compound hydrophobic agent in this embodiment are shown in Table 1 below:

[0069] Table 1

[0070]

[0071] The preparation method of the above-mentioned compound foaming agent is...

Embodiment 2

[0077] This embodiment relates to an oil-resistant freeze-thaw resistant fire door core board and its preparation method. The fire door core board is composed of the following raw materials in parts by weight:

[0078] 46 parts of niobium yttrium tailings powder;

[0079] Phosphogypsum powder 19 parts;

[0080] 22 parts of pyrophyllite powder;

[0081] 6.5 parts of palm leaf fiber;

[0082] 12 parts of pozzolan Portland cement;

[0083] 2.5 parts of maleic anhydride grafted polypropylene;

[0084] 3.5 parts of ZK-9 rubber powder;

[0085] Dispersant FT-781.3 parts:

[0086] 2.4 parts of compound coupling agent;

[0087] 3.5 parts of compound blowing agent;

[0088] Compound water repellent 1.7 parts.

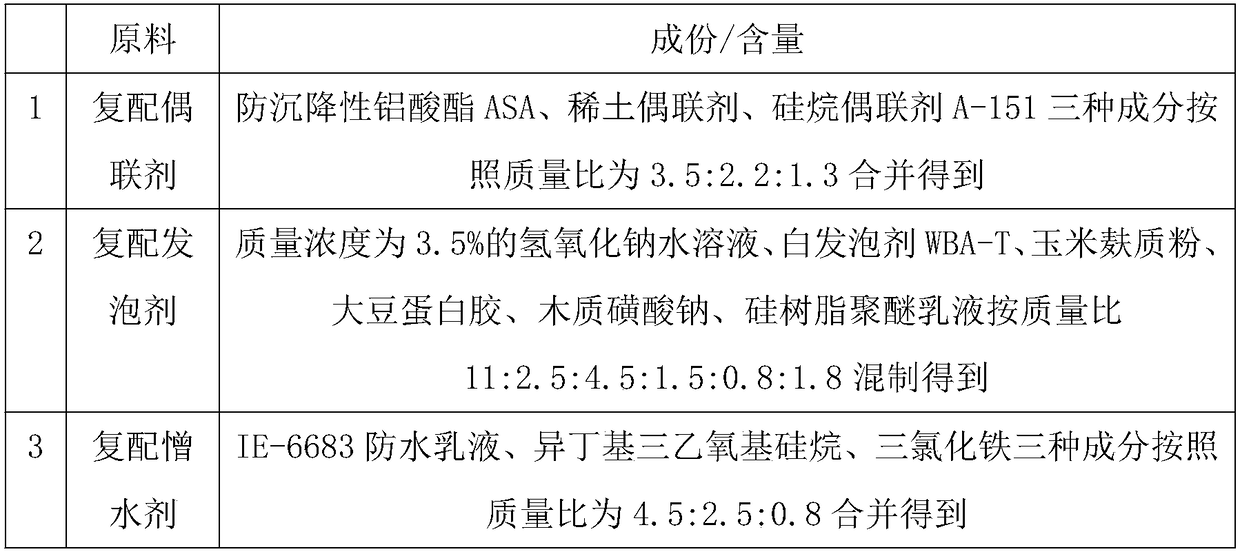

[0089] The selection and preparation of the compound coupling agent, compound blowing agent and compound hydrophobic agent in this embodiment are shown in Table 2 below:

[0090] Table 2

[0091]

[0092] The preparation method of the above-mentioned compound foamin...

Embodiment 3

[0098] This embodiment relates to an oil-resistant freeze-thaw resistant fire door core board and its preparation method. The fire door core board is composed of the following raw materials in parts by weight:

[0099] 48 parts of niobium yttrium tailings powder;

[0100] Phosphogypsum powder 20 parts;

[0101] 25 parts of pyrophyllite powder;

[0102] 7 parts palm leaf fiber;

[0103] 13 parts of pozzolan Portland cement;

[0104] 2.8 parts of maleic anhydride grafted polypropylene;

[0105] 4 parts of ZK-9 rubber powder;

[0106] Dispersant FT-781.5 parts:

[0107] 2.5 parts of compound coupling agent;

[0108] 4 parts of compound foaming agent;

[0109] Compound water repellent 2 parts.

[0110] The selection and preparation of the compound coupling agent, compound foaming agent and compound hydrophobic agent in this embodiment are shown in Table 3 below:

[0111] table 3

[0112]

[0113] The preparation method of the above-mentioned compound foaming agent is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com