A kind of preparation method of nano W-xcu alloy, nano W-xcu alloy

An alloy and nanotechnology, applied in nanotechnology, nanotechnology, metal processing equipment, etc., can solve the problems of complicated operation, reduced product quality, uneven mixing of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

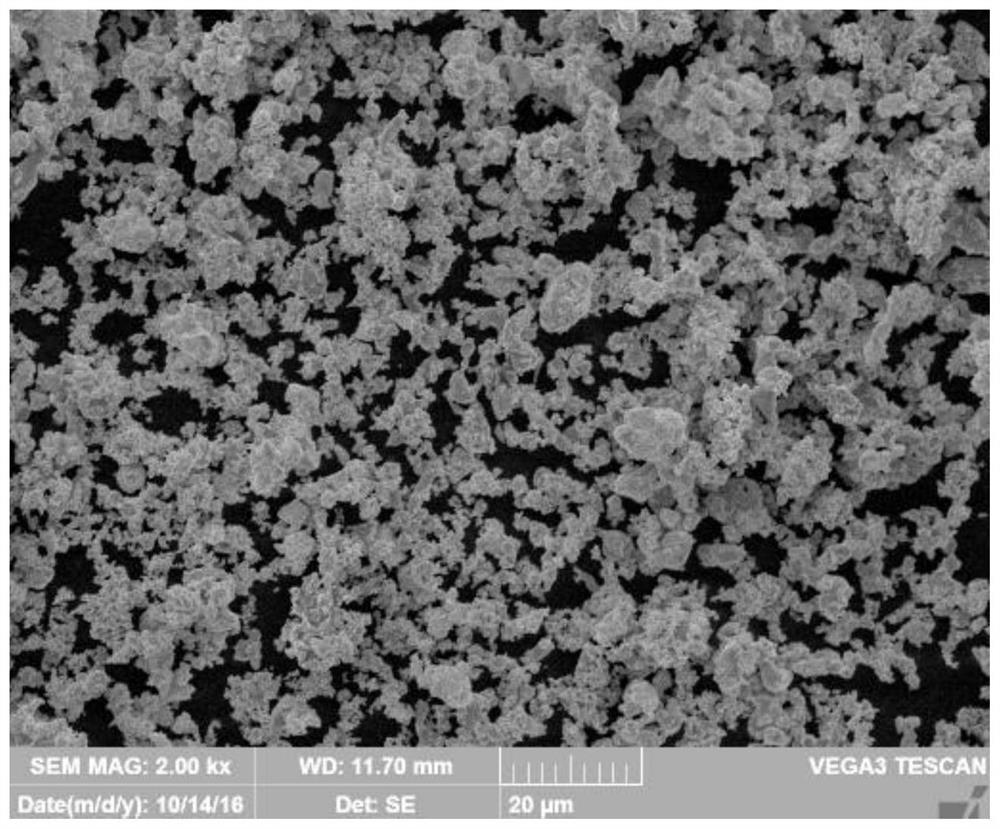

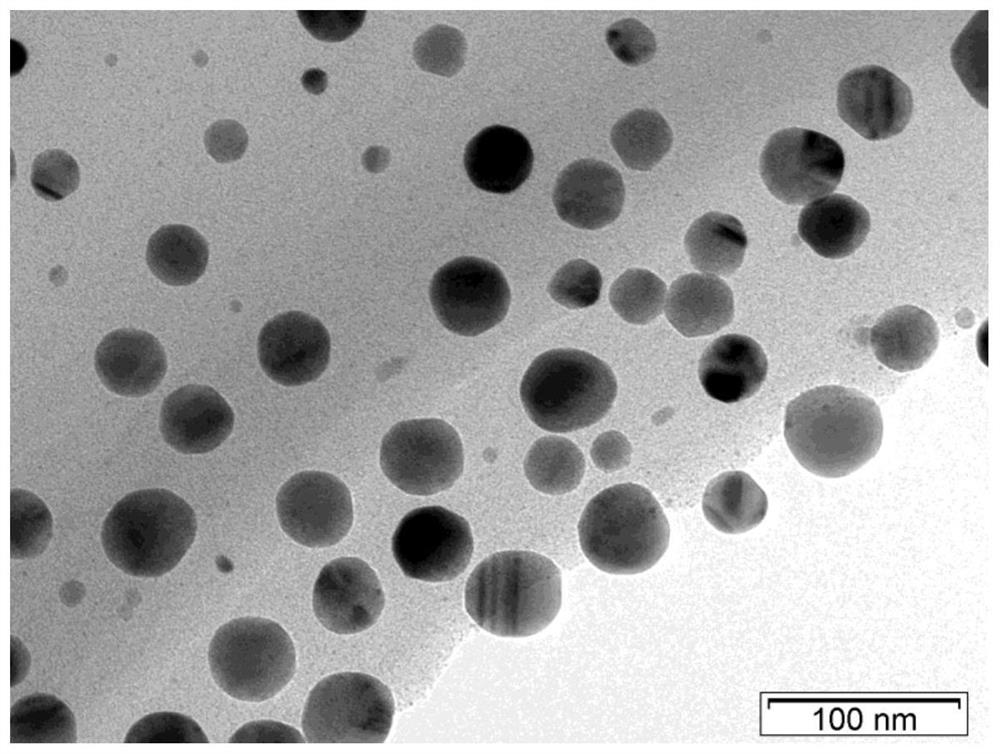

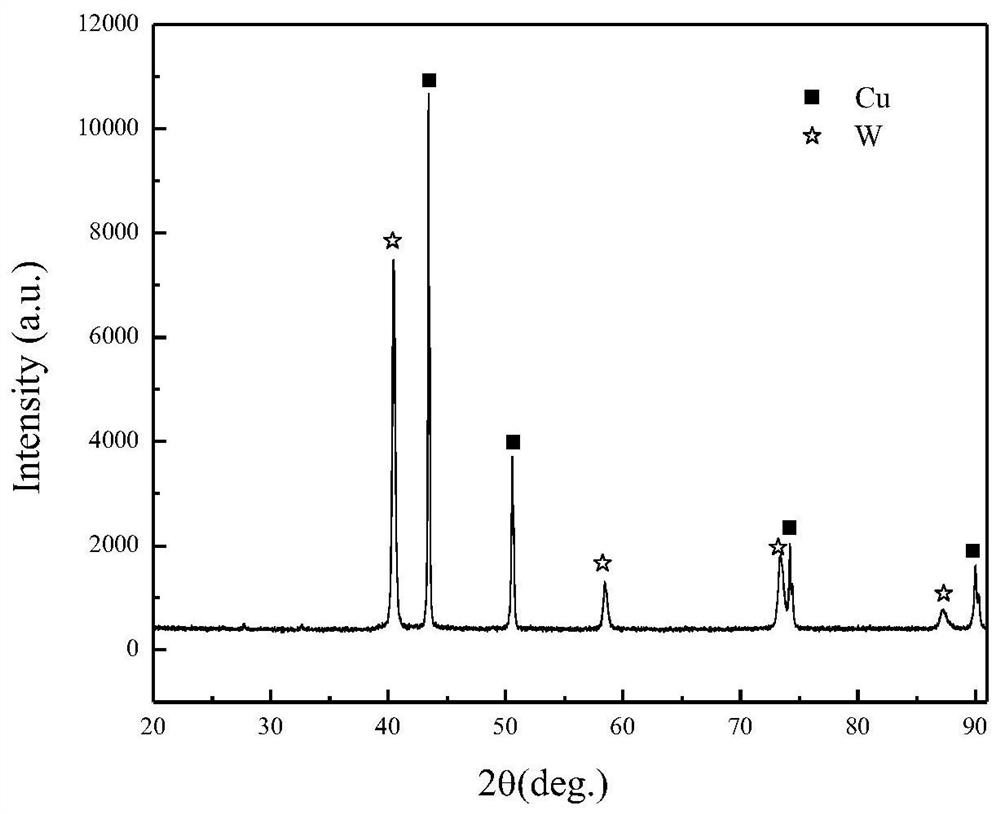

[0037] The preparation method of nanometer W-70Cu alloy in the present embodiment, comprises the following steps:

[0038] 1) Take 31.14g of CuWO 4 Mix with 1000mL ammonia water to get CuWO 4 solution;

[0039] 2) Add 45.74g of CuO to the solution, using NH 3 ·H 2 O adjusts the pH to 6.5 to obtain a mixture system;

[0040] 3) Transfer the mixture system to a polytetrafluoroethylene-lined hydrothermal reaction kettle, place it in a drying oven at 150°C for 15 hours, then take it out and cool it at room temperature to obtain a hydrothermal product;

[0041] 4) Put the hydrothermal product in the funnel, slowly add water into the funnel, wash with water for 3 times by suction filtration; then add ethanol for suction filtration and wash 3 times; then dry at 70°C for 5 hours to obtain nano-sized tungsten-copper precursor powder;

[0042] 5) Place the nanoscale tungsten copper precursor powder in the reduction furnace with a flow rate of 1m 3 / h of hydrogen, heat up to 400°C ...

Embodiment 2

[0046] The preparation method of the nano W-65Cu alloy with controllable copper content in the present embodiment comprises the following steps:

[0047] 1) Take 31.14g of CuWO 4 Mix with 1000mL ammonia water to get CuWO 4 solution;

[0048] 2) Add 34.71 g of CuO to the solution, using NH 3 ·H 2 O adjusts the pH to 7 to obtain a mixture system;

[0049] 3) Transfer the mixture system to a polytetrafluoroethylene-lined hydrothermal reaction kettle, place it in a drying oven at 175°C for 18 hours, then take it out and cool it at room temperature to obtain a hydrothermal product;

[0050] 4) Put the hydrothermal product in the funnel, slowly add water into the funnel, wash with water for 4 times by suction filtration; then add ethanol for suction filtration and wash 3 times; then dry at 80°C for 7 hours to obtain nano-sized tungsten-copper precursor powder;

[0051] 5) Place the nanoscale tungsten copper precursor powder in the reduction furnace with a flow rate of 3m 3 / h of...

Embodiment 3

[0054] The preparation method of nanometer W-60Cu alloy in the present embodiment, comprises the steps:

[0055] 1) Take 31.14g of CuWO 4 Mix with 1000mL ammonia water to get CuWO 4 solution;

[0056] 2) Add 26.56g of CuO to the solution, using NH 3 ·H 2 O adjusts the pH to 7.5 to obtain a mixture system;

[0057] 3) Transfer the mixture system to a polytetrafluoroethylene-lined hydrothermal reaction kettle, place it in a drying oven at 200°C for 20 hours, then take it out and cool it at room temperature to obtain a hydrothermal product;

[0058] 4) Put the hydrothermal product in the funnel, slowly add water into the funnel, wash with water for 5 times by suction filtration; then add ethanol for suction filtration and wash 3 times; then dry at 90°C for 10 hours to obtain nano-sized tungsten-copper precursor powder;

[0059] 5) Place the nanoscale tungsten copper precursor powder in the reduction furnace with a flow rate of 5m 3 / h of hydrogen, heat up to 500°C at a heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com