Preparation method of helium-containing W-based nanocrystalline film material

A technology of thin film materials and nanocrystals, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve problems such as radio frequency magnetron sputtering that have not been seen, and meet the needs of large-scale sample research. The effect of the simple and easy operation of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

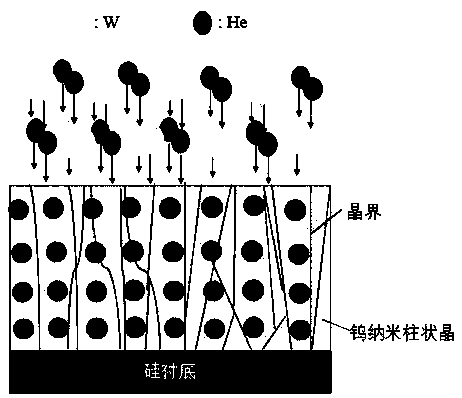

[0027] This embodiment provides a preparation method of helium-containing W-based nanocrystalline film material, such as figure 1 shown, including the following steps:

[0028] Step 1: Perform surface treatment on the W target (the thickness of the W target is 2mm), remove surface metal oxides and impurities, and obtain the metal W target to be sputtered;

[0029] Step 2: Ultrasonic cleaning the single crystal Si substrate with a mixed solution of alcohol and acetone, finally rinsing with deionized water, and drying;

[0030] Step 3: Install the W target of step 1 on the permanent magnet target of magnetron sputtering, place the substrate of step 2 on the substrate inside the magnetron sputtering apparatus, and evacuate to 8×10 -5 Pa, into a He / Ar mixed atmosphere for sputtering deposition for 5 hours, wherein the total pressure of the He / Ar mixed gas is 2 Pa, and the He / Ar pressure ratio is 5; the deposition temperature of the single crystal Si substrate is normal temperatur...

Embodiment 2

[0039] This embodiment provides a method for preparing a helium-containing W-based nanocrystalline thin film material. Compared with Example 1, the process parameters in Step 2 and Step 3 are the same, except that the W-based target used in Step 1 is W Alloy target (oxide dispersed W or carbide dispersed W).

[0040]The helium-containing W-based nanocrystalline thin film material obtained by the method described in this embodiment was tested according to the method described in Example 1, and the results showed that:

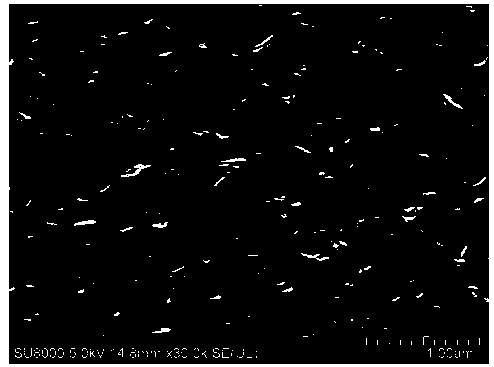

[0041] The grain size of helium-containing W-based nanocrystalline thin film material is about 100nm, which is in line with the size range of nanocrystalline materials;

[0042] The crystal structure of the helium-containing W nanocrystalline film material is a typical nano-columnar crystal, and the film thickness is in the range of 10nm-100μm.

[0043] The distribution of helium bubbles in the helium-containing W nanocrystalline thin film material is uniform, ...

Embodiment 3

[0045] This embodiment provides a method for preparing a helium-containing W-based nanocrystalline thin film material. Compared with Embodiment 1, the process parameters in Step 1 and Step 3 are the same, and the difference is that the substrate in Step 2 is a ceramic substrate. .

[0046] The helium-containing W-based nanocrystalline thin film material obtained by the method described in this embodiment was tested according to the method described in Example 1, and the results showed that:

[0047] The grain size of helium-containing W-based nanocrystalline thin film material is about 100nm, which is in line with the size range of nanocrystalline materials;

[0048] The crystal structure of the helium-containing W nanocrystalline film material is a typical nano-columnar crystal, and the film thickness is in the range of 10nm-100μm.

[0049] The distribution of helium bubbles in the helium-containing W nanocrystalline thin film material is uniform, and the average size of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com