Large-area and graphical transition metal sulfide thin film preparation methods

A transition metal and transition group metal technology, which is applied in the field of preparation of large-area and patterned transition metal sulfide thin films, can solve the problems of inability to realize patterned thin film preparation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of a large-area platinum diselenide thin film:

[0029] 1) Select a silicon wafer grown by thermal oxidation of 300nm silicon dioxide, with an area of 3 square centimeters, and clean it;

[0030] 2) Deposition of platinum metal film: use magnetron sputtering to grow platinum with a thickness of 3nm on the cleaned substrate;

[0031] 3) Synthesis in a chemical vapor deposition system: Place the selenium powder upstream of the platinum metal film, and set its heating temperature to 220°C, so that the selenium powder is in a molten state, and then make the lining with the platinum metal film grow The bottom is placed at 400°C, H 2 Set as 10SCCM, Ar as 100SCCM flow rate, air pressure as 70Pa, in H 2 Under the action of Ar and Ar, the selenium atoms are transported to the platinum atoms and combined to form platinum diselenide. The synthesis time is 60 minutes. During the synthesis process, the vacuum pump is used to keep the cavity in a low pressure state. A...

Embodiment 2

[0033] The difference from Example 1 is that step 2) deposition of platinum metal film: use magnetron sputtering to grow platinum with a thickness of 1 nm on the cleaned substrate;

[0034] The platinum diselenide thin film prepared in embodiment 1 is characterized,

[0035] (1) Characterization of the morphology of platinum diselenide

[0036] refer to figure 1 , it can be seen that the platinum diselenide prepared in Example 1 presents the characteristics of large area, uniformity and continuity, which meets the needs of large area preparation.

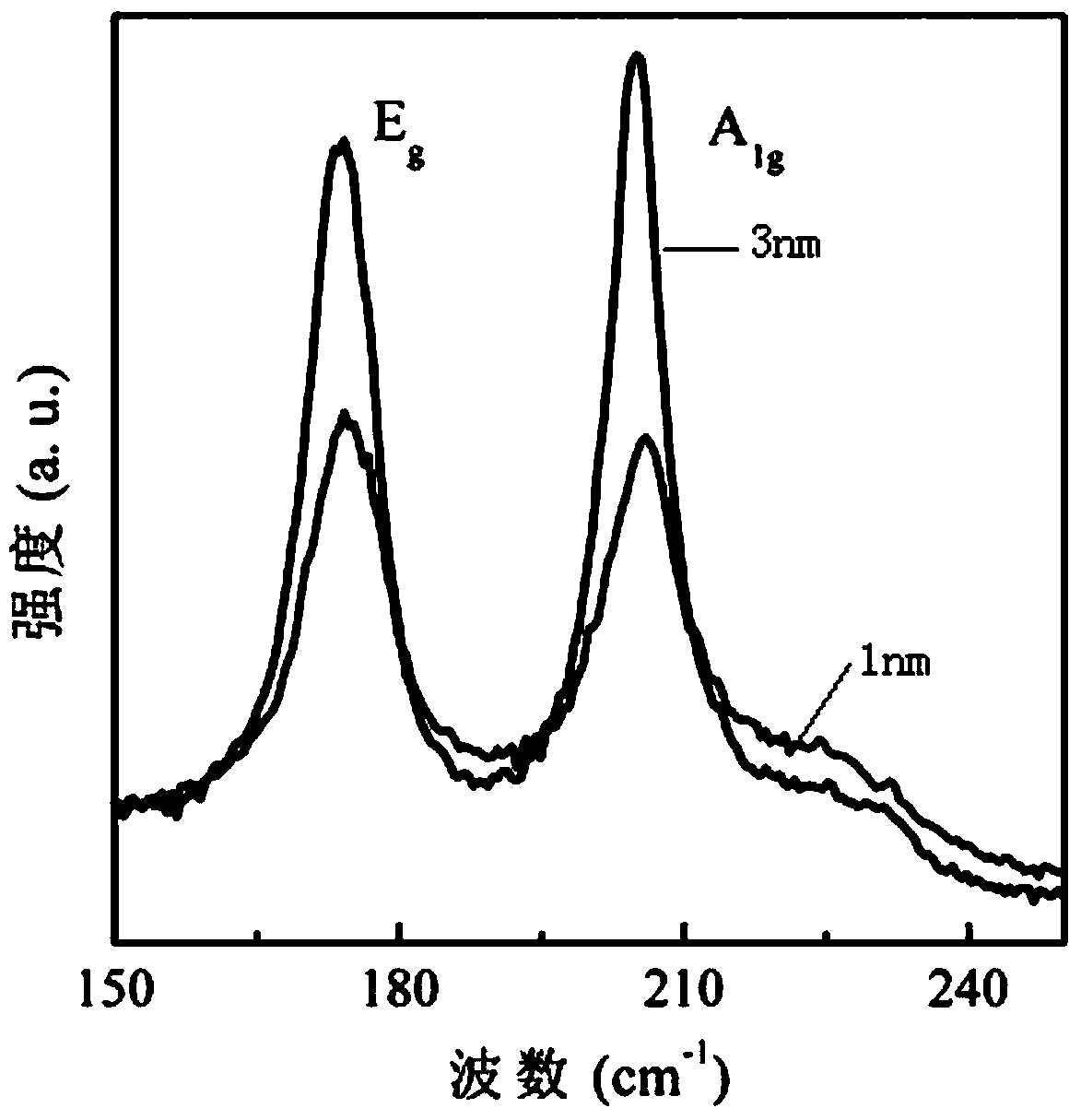

[0037] (2) Raman spectrum characterization of platinum diselenide

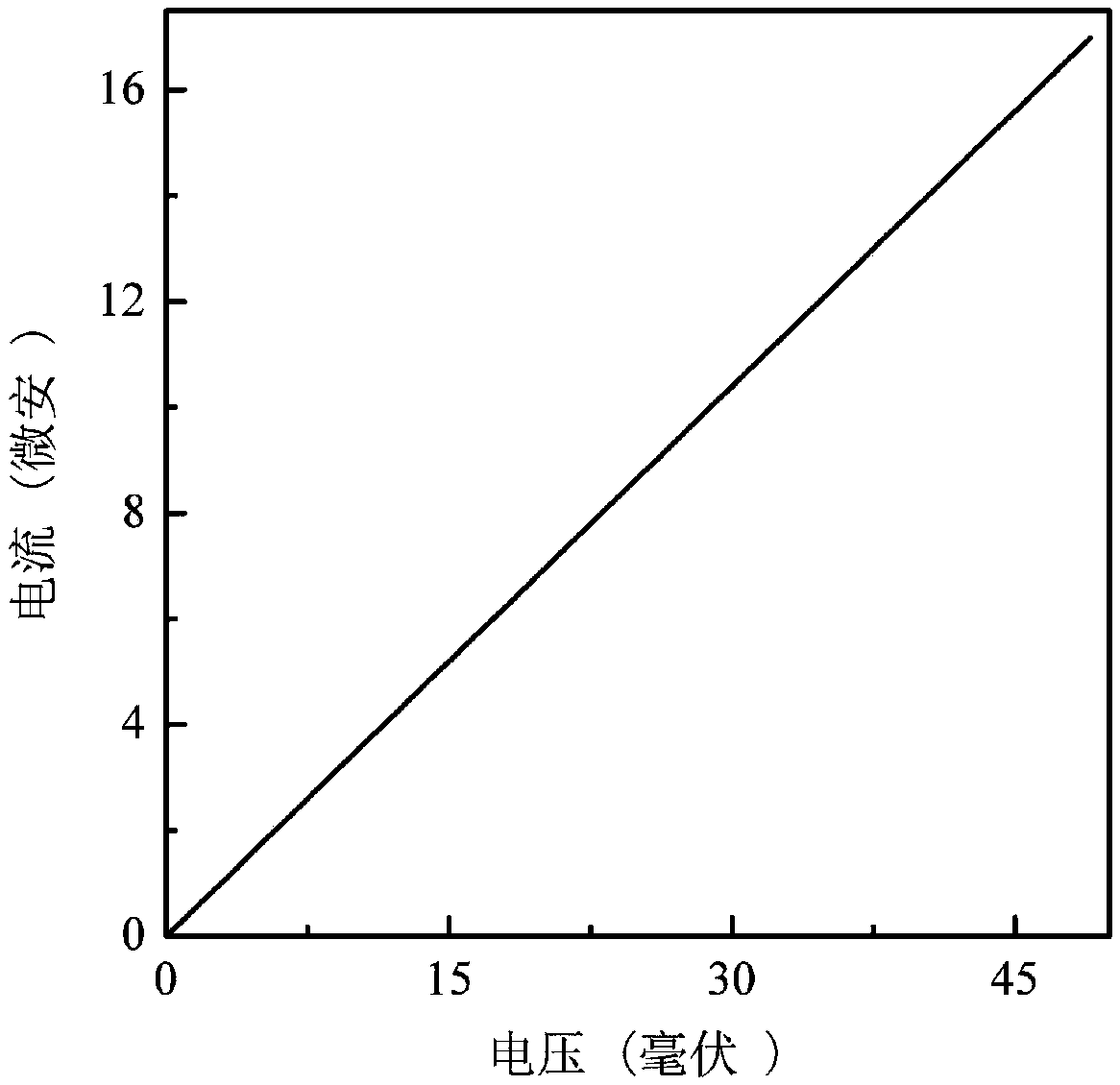

[0038] Platinum diselenide is a kind of transition metal sulfide, and the layers are combined by weak van der Waals force, so in addition to the lattice vibration in the plane, there is also the interaction between the planes, Raman spectroscopy as The means of detecting phonon vibration characteristics can also be used to characterize platinum diselenide and obt...

Embodiment 3

[0042] The method that present embodiment prepares molybdenum disulfide comprises the steps:

[0043] (1) Gallium nitride wafer is selected as the substrate material, and gallium nitride is cleaned.

[0044] (2) Deposition of molybdenum metal film: Molybdenum with a thickness of 10 nm was grown on the cleaned substrate by magnetron sputtering.

[0045] (3) Synthesis in chemical vapor deposition system: at 600°C, H 2 Set to 20SCCM, Ar to 120SCCM flow rate, air pressure to 600Pa, and synthesis time to 90 minutes. During the synthesis process, a vacuum pump is used to keep the chamber in a low pressure state. After the synthesis is completed, the temperature of the system is lowered to room temperature, and the grown samples can be taken out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com