Method for treating magnesium extraction raffinate wastewater

A waste water and raffinate technology, applied in the direction of filtration treatment, sedimentation treatment, multi-stage water treatment, etc., can solve the problems of complex process, waste of resources, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

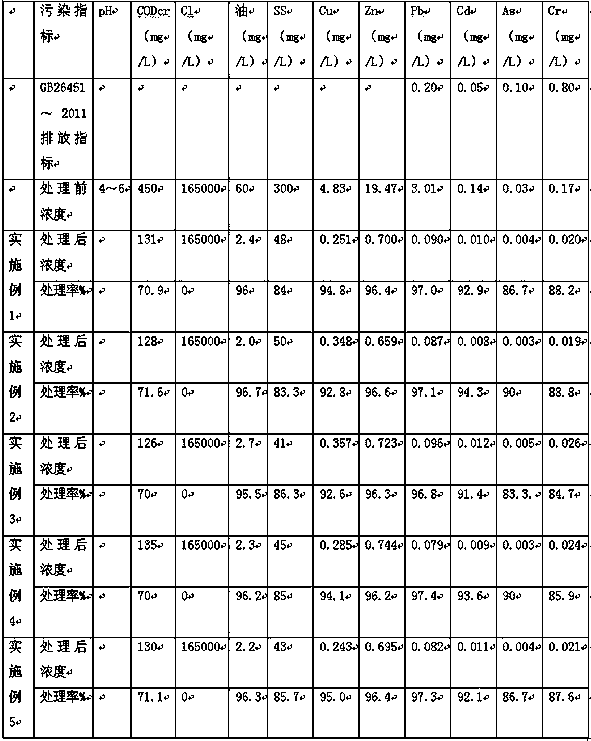

Examples

Embodiment 1

[0021] (1) Recovery of extraction agent: discharge the magnesium raffinate waste water to the bottom of the grease trap in the grease trap, install an adjustable vibration device, turn on the slight amplitude, and the frequency of vibration is 250Hz to vibrate the waste water for 11 minutes, and after standing for 2.5 hours to separate layers, Recover the extractant to obtain crude magnesium chloride wastewater;

[0022] (2) Preparation of demulsifier: Add 0.7 parts of polyacrylate to 8 parts of guar gum as the initiator, add magnesium hydroxide to catalyze the addition polymerization reaction chain extension under alkaline conditions, then add 1.8 parts of pentaerythritol to branch chemically, to obtain a demulsifier;

[0023] (3) Demulsification: pass the crude magnesium chloride wastewater obtained in step (1) through the demulsification reaction bed, add a demulsifier for demulsification reaction, demulsification at a stirring rate of 880r / min for 8min, an ultrasonic frequ...

Embodiment 2

[0029] (1) Recovering the extraction agent: discharge the magnesium raffinate waste water to the bottom of the grease trap in the grease trap, install an adjustable vibration device, turn on a slight amplitude, and vibrate at a frequency of 300 Hz to vibrate the waste water for 10 minutes. After standing for 2 hours and stratify, recover Extractant, get crude magnesium chloride waste water;

[0030] (2) Preparation of demulsifier: Add 0.5 parts of polyacrylate to 9 parts of guar gum as the starting agent, add magnesium hydroxide to catalyze the addition polymerization reaction chain extension under alkaline conditions, and then add 2.4 parts of glycerin for branching , to obtain a demulsifier;

[0031] (3) Demulsification: pass the crude magnesium chloride wastewater obtained in step (1) through the demulsification reaction bed, add a demulsifier for demulsification reaction, demulsification at a stirring rate of 950r / min for 9min, ultrasonic frequency 26kHz, mixing ratio 1:1....

Embodiment 3

[0037] (1) Recovery of extraction agent: discharge the magnesium extract waste water to the bottom of the grease trap, install an adjustable vibration device, turn on the slight amplitude, the frequency of vibration is 350Hz to vibrate the waste water for 12 minutes, and after standing for 3 hours to separate, recover Extractant, get crude magnesium chloride waste water;

[0038] (2) Preparation of demulsifier: Add 0.8 parts of polyacrylate to 5 parts of guar gum as the starting agent, add magnesium hydroxide to catalyze the addition polymerization reaction chain extension under alkaline conditions, and then add 2 parts of trimethylol Ethane is branched to produce a demulsifier;

[0039] (3) Demulsification: pass the crude magnesium chloride wastewater obtained in step (1) through the demulsification reaction bed, add demulsifier for demulsification reaction, demulsification at a stirring rate of 900r / min for 10min, ultrasonic frequency 27kHz, mixing ratio 1:1, Remove the emu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com