Spherical TiC powder and preparation method thereof

A spherical and powder technology, which is applied in the field of spherical TiC powder and its preparation, can solve the problems of oxide instability, alloy structure instability and compactness, etc., and achieve good fluidity, good industrialization prospects, and high compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

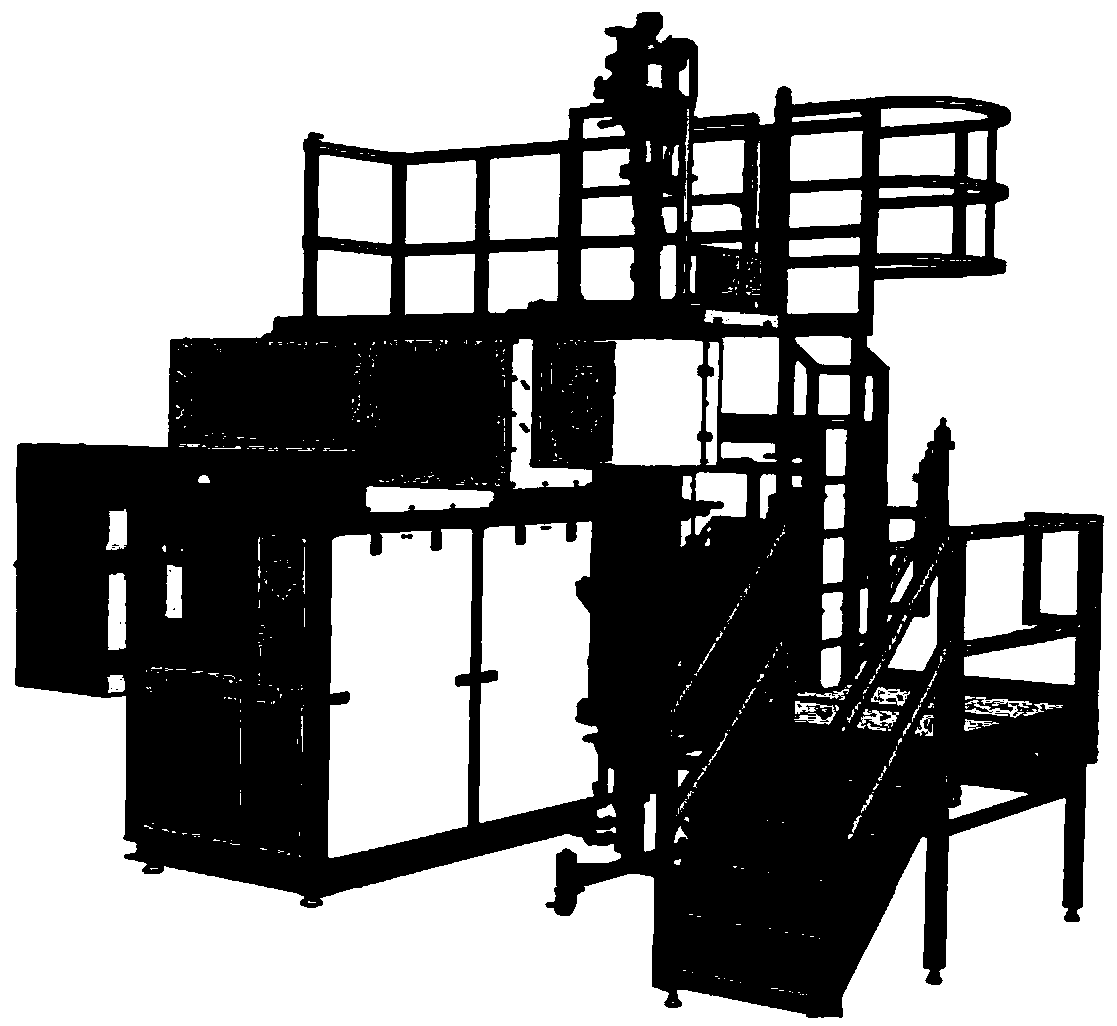

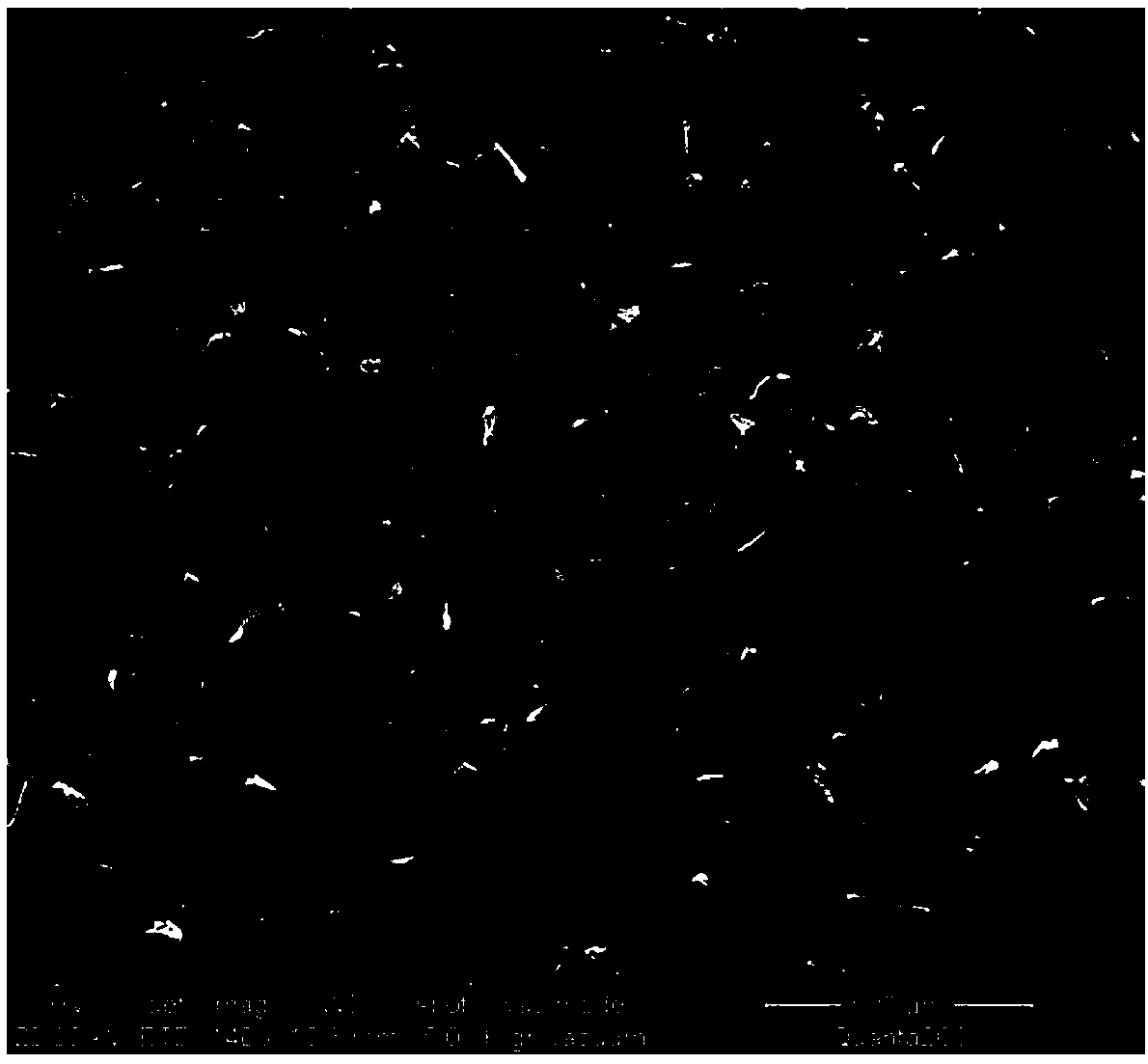

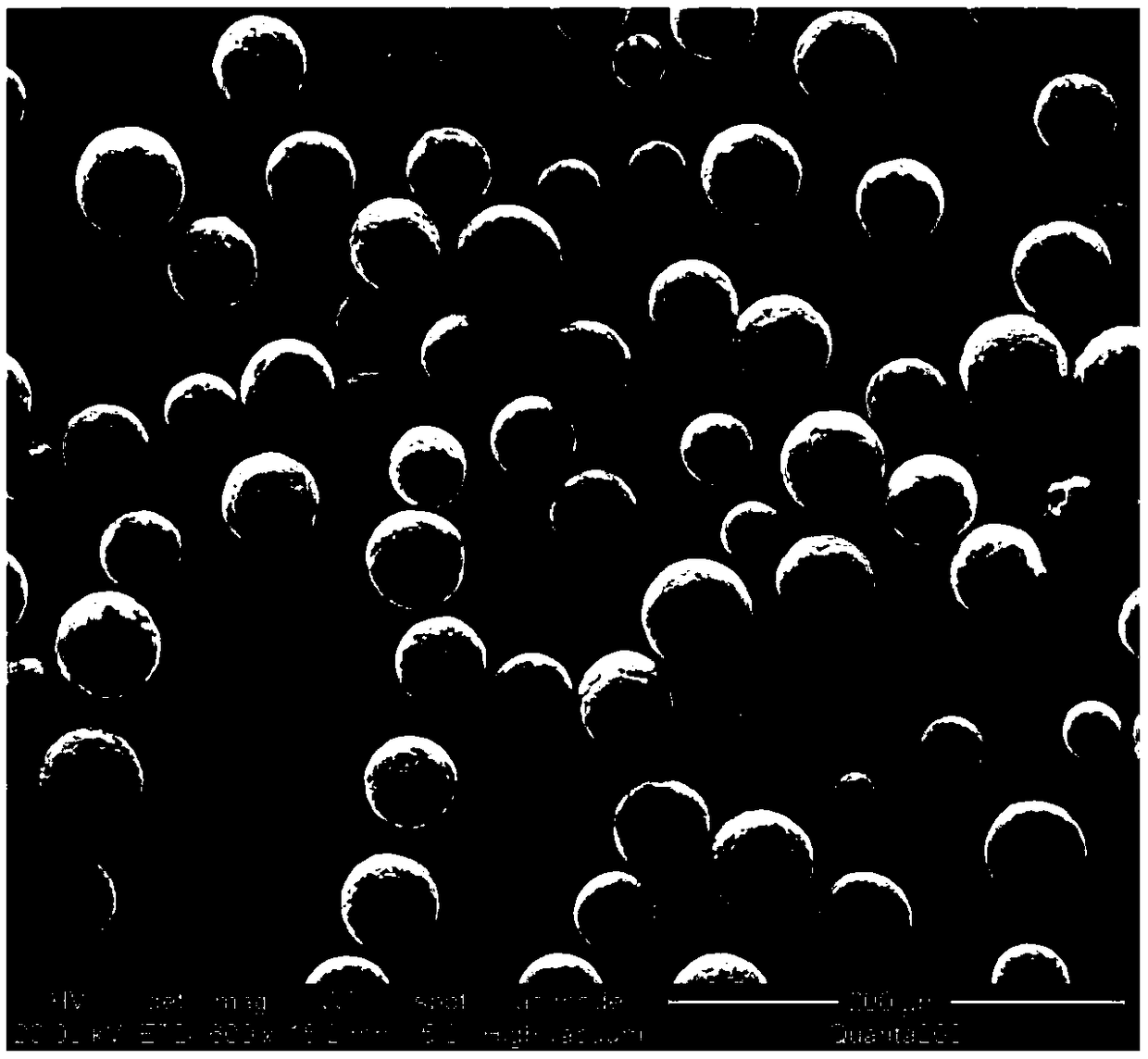

Embodiment 1

[0031] The preparation method of the micron spherical titanium carbide powder adopts the original titanium carbide powder with irregular shape as the raw material, and the powder specification is 15-53 μm. (1) In the sieving system, the raw TiC powder is sieved. The sieving equipment model used is Artech, and the particle size of the sieved powder is 15-45 μm. (2) In the plasma spheroidization system, the original powder is spheroidized; the model of the radio frequency plasma spheroidization equipment used is TekSphero-40KW SY165. The spheroidization parameters are set as follows: powder feeder probe model is SI792, powder feeding gap is 1mm, probe height is -10mm, powder feeder speed is 2r / min, argon sheath flow rate is 50splm, hydrogen sheath flow rate is 6splm, argon central The air flow rate is 20splm, and the powder feeding gas flow rate is 3splm. (3) In the cleaning equipment, the powder after spheroidization is cleaned and classified; the cleaning process of the spher...

Embodiment 2

[0033] The preparation method of micron-sized spherical titanium carbide powder, the raw material adopts irregularly shaped original titanium carbide powder, and the powder specification is 15-53 μm. (1) In the screening system, the original powder TiC powder is screened; the screening equipment used The model is Artech, and the particle size of the sieved powder is 15-45 μm. (2) In the plasma spheroidization system, the original powder is spheroidized; the model of the radio frequency plasma spheroidization equipment used is TekSphero-40KW SY165. The spheroidization parameters are set as follows: powder feeder probe model is SI792, powder feeding gap is 1mm, probe height is -10mm, powder feeder speed is 2r / min, argon sheath flow rate is 50splm, hydrogen sheath flow rate is 9splm, argon central The air flow rate is 20splm, and the powder feeding gas flow rate is 3splm. (3) In the cleaning equipment, the powder after spheroidization is cleaned and classified; the cleaning proc...

Embodiment 3

[0035]The preparation method of the micron spherical titanium carbide powder adopts the original titanium carbide powder with irregular shape as the raw material, and the powder specification is 15-53 μm. (1) In the screening system, the original TiC powder is screened; the type of screening equipment used is Artech, and the particle size of the screened powder is 15-45 μm. (2) In the plasma spheroidization system, the original powder is spheroidized; the model of the radio frequency plasma spheroidization equipment used is TekSphero-40KW SY165. Spheroidization parameters are set as follows: powder feeder probe model is SI792, powder feeding gap is 1mm, probe height is -10mm, powder feeder speed is 2r / min, argon sheath flow rate is 50splm, hydrogen sheath flow rate is 12splm, argon central The air flow rate is 20splm, and the powder feeding gas flow rate is 3splm. (3) In the cleaning equipment, the powder after spheroidization is cleaned and classified; the cleaning process o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com