Preparation method of sulfydryl chitosan photochromic microcapsule and material prepared from sulfydryl chitosan photochromic microcapsule and application thereof

A technology of photochromism and chitosan, which is applied in the direction of microcapsule preparation, microsphere preparation, textile and paper making, etc., can solve the problem of formaldehyde release, and achieve the effect of easy operation, green preparation method and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

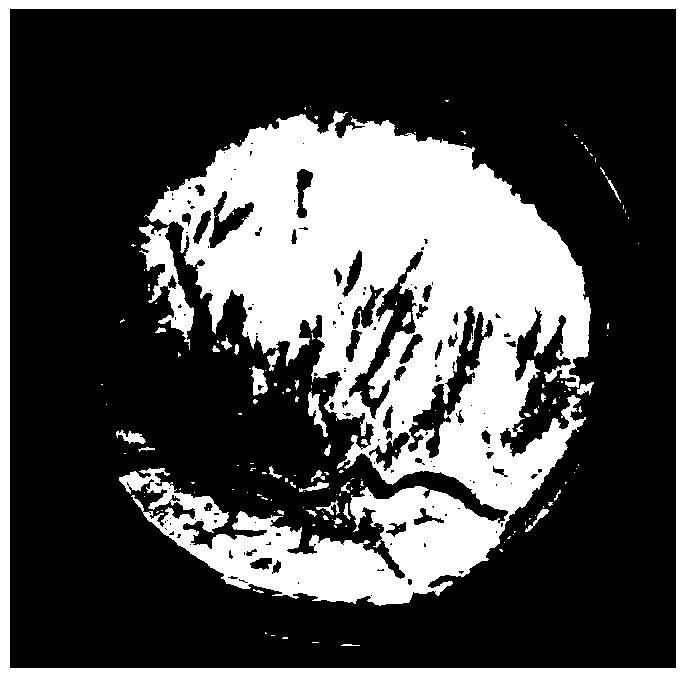

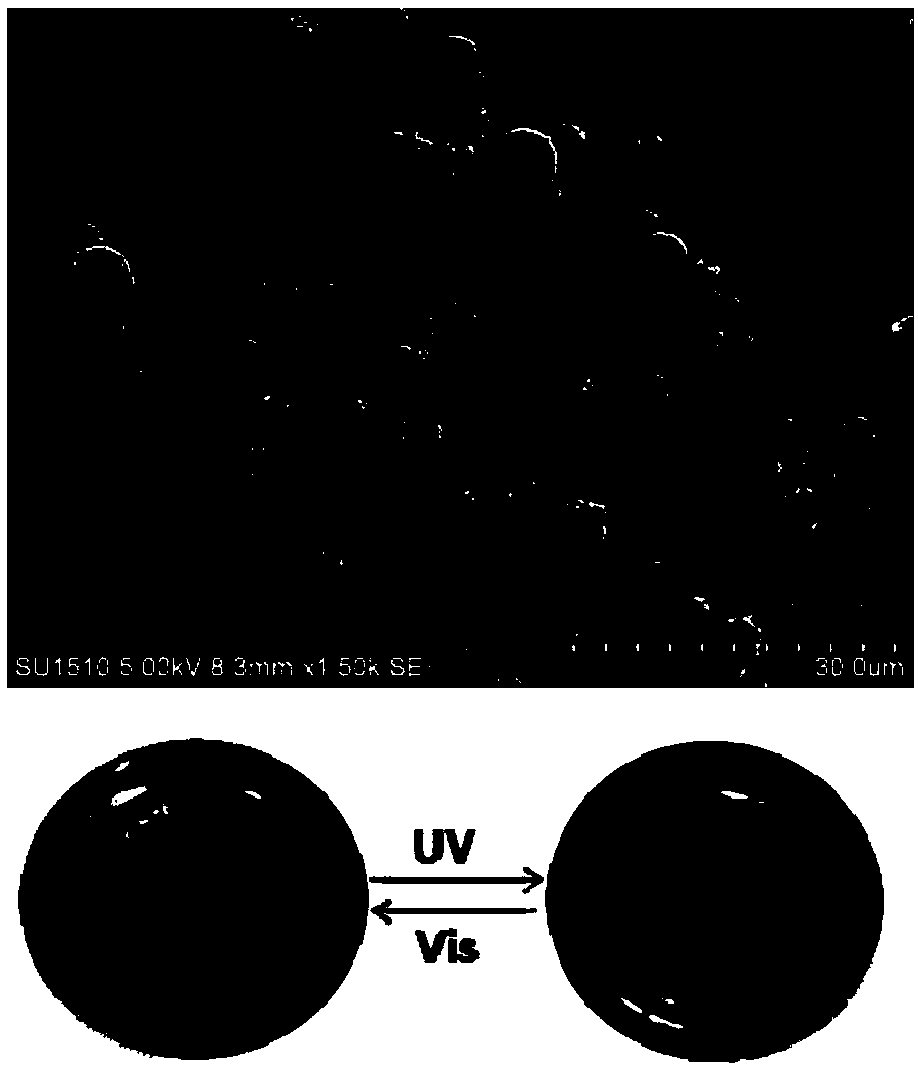

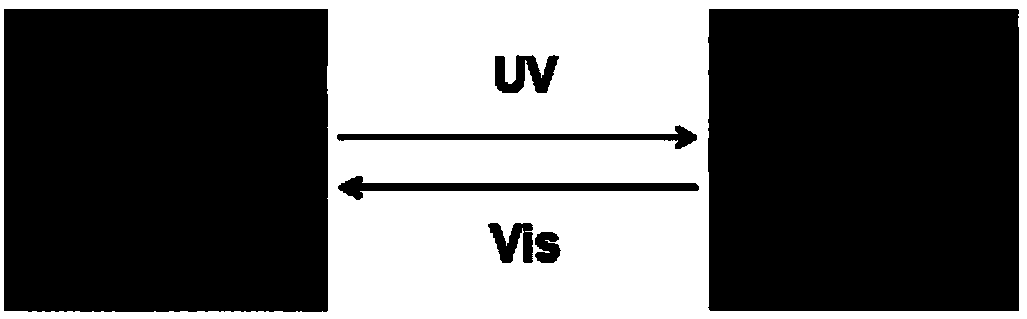

Image

Examples

Embodiment 1

[0036] A method for applying thiol chitosan photochromic microcapsules to fabrics, the process is as follows:

[0037] The four substances of carbodiimide hydrochloride, N-hydroxysuccinimide, mercapto compound and N,N-dimethylformamide were mixed and stirred at a molar ratio of 1:1:1:0.5 for 12h. Chitosan with a degree of deacetylation of 70% was dissolved in a 1 mol / L hydrochloric acid solution to finally obtain a 2.5% chitosan hydrochloric acid solution. The chitosan hydrochloric acid solution was added to the mixed solution of the above four substances. The pH value was adjusted to 5.0 with sodium hydroxide solution, and the mixture was put into a dialysis bag for dialysis treatment after stirring for 12 hours, and finally freeze-dried to obtain thiol chitosan.

[0038] 0.05 g of thiol chitosan was dissolved in 20 mL of an acetic acid solution with a mass fraction of 1%, and stirred at room temperature until dissolved. Add 0.01 g of spiropyran photochromic dye to 10 mL of...

Embodiment 2

[0041] A method for applying thiol chitosan photochromic microcapsules to fabrics, the process is as follows:

[0042] The four substances of carbodiimide hydrochloride, N-hydroxysuccinimide, mercapto compound and N,N-dimethylformamide were mixed and stirred at a molar ratio of 1:1:1.25:0.7 for 12 hours. Chitosan with a degree of deacetylation of 85% was dissolved in a 1wt% acetic acid solution to finally obtain a 2% chitosan acetic acid solution. The chitosan acetic acid solution was added to the mixed solution of the above four substances. The pH value was adjusted to 5.0 with sodium hydroxide solution, and the mixture was put into a dialysis bag for dialysis treatment after stirring for 12 hours, and finally freeze-dried to obtain thiol chitosan.

[0043] 0.05 g of thiol chitosan was dissolved in 20 mL of a formic acid solution with a mass fraction of 2%, and stirred at room temperature until dissolved. Add 0.01 g of spirooxazine photochromic dye to 10 mL of a mixed emuls...

Embodiment 3

[0046] A method for applying thiol chitosan photochromic microcapsules to fabrics, the process is as follows:

[0047] The four substances of carbodiimide hydrochloride, N-hydroxysuccinimide, mercapto compound and N,N-dimethylformamide were mixed and stirred at a molar ratio of 1:1:1.2:0.75 for 12h. Chitosan with a degree of deacetylation of 90% was dissolved in a 5wt% citric acid solution to finally obtain a 4% chitosan citric acid solution. The chitosan citric acid solution was added to the mixed solution of the above four substances. The pH value was adjusted to 5.0 with sodium hydroxide solution, and the mixture was put into a dialysis bag for dialysis treatment after stirring for 12 hours, and finally freeze-dried to obtain thiol chitosan.

[0048] 0.05 g of thiol chitosan was dissolved in 20 mL of a citric acid solution with a mass fraction of 1%, and stirred at room temperature until dissolved. Add 0.01 g of diarylene photochromic dye to 10 mL of a mixed emulsifier so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com