A sodium ion capacitor with high energy density and high power density and preparation method thereof

A high power density, high energy density technology, applied in the field of sodium ion capacitors with both high energy density and high power density and their preparation, can solve problems such as difficulty in meeting actual use requirements, low energy density and power density, etc. The effect of energy density, high power density, high energy density or power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

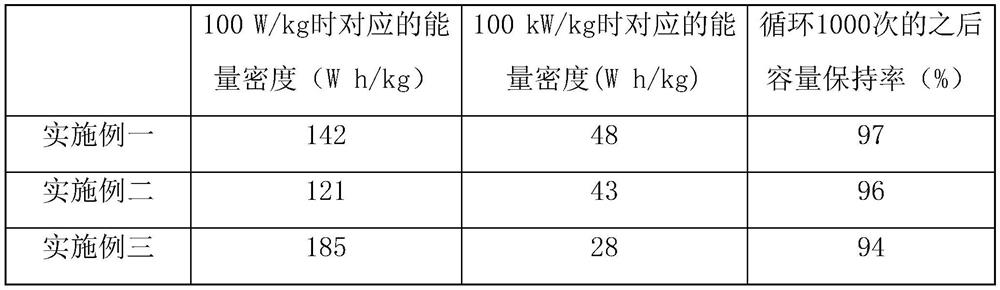

Embodiment 1

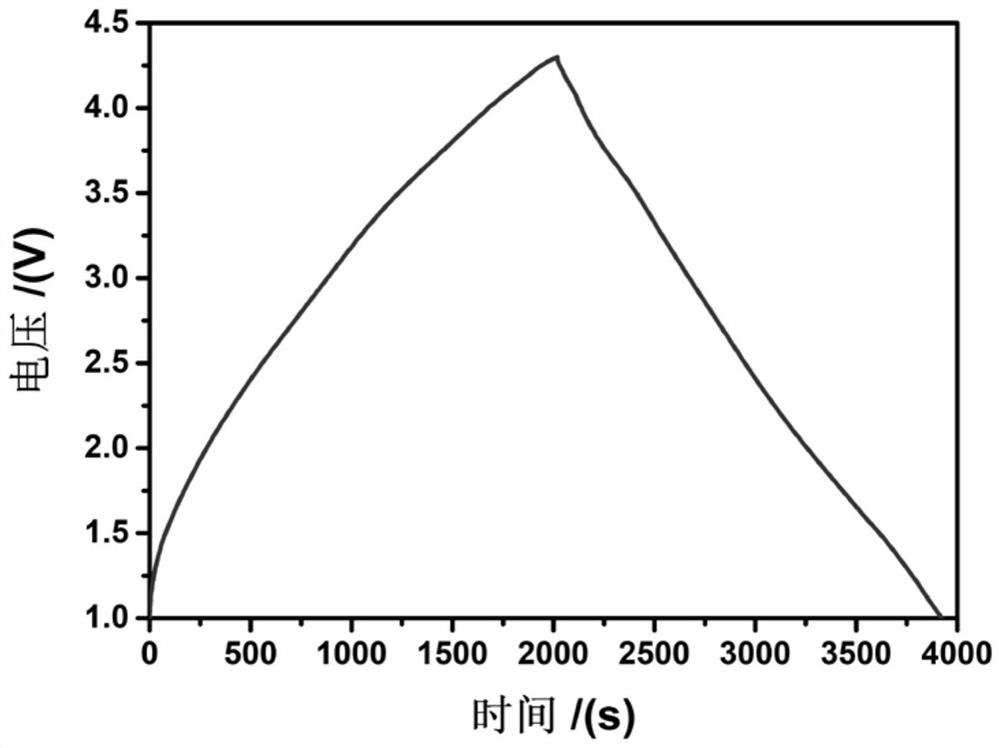

[0020] A method for preparing a sodium ion capacitor having both high energy density and high power density, comprising the following steps:

[0021] Step 1, the specific surface area is 600m 2 / g, the pore volume is 0.8cm 3 / g of graphene-based porous carbon, mixed with conductive carbon black (superP), and binder PVDF according to the mass ratio of 80:10:10, adding organic solvent NMP (4:1 to porous carbon mass ratio) to obtain positive electrode slurry . The positive electrode slurry is coated on the aluminum foil, and after drying, rolling and punching, the positive electrode sheet of the sodium ion capacitor is obtained, that is, the porous carbon electrode sheet.

[0022] Step 2: Ultrasonic dispersion of graphene oxide and ammonium tetrathiomolybdate with a mass ratio of 2:5 and an appropriate amount of DMF (N, N-dimethylformamide), fully mixed and transferred to the polytetrafluoroethylene liner Solvothermal reaction at 190° C. for 18 hours in a closed reaction kettl...

Embodiment 2

[0026] A method for preparing a sodium ion capacitor having both high energy density and high power density, comprising the following steps:

[0027] Step 1, the specific surface area is 1200m 2 / g, the pore volume is 1.0cm 3 / g of activated carbon, mixed with conductive carbon black (superP) and binder PVDF according to the mass ratio of 75:10:15, and the organic solvent NMP (mass ratio of porous carbon: 4:1) was added to obtain the positive electrode slurry. The positive electrode slurry is coated on the aluminum foil, and after drying, rolling and punching, the positive electrode sheet of the sodium ion capacitor is obtained, that is, the porous carbon electrode sheet.

[0028] Step 2, fully mix 2 mg / ml graphene oxide ultrasonic dispersion with 2 mg / ml few-layer molybdenum disulfide ultrasonic dispersion, the volume ratio of graphene and molybdenum disulfide dispersion is 2:3. After fully mixing, dry at 180°C, heat to 800°C under an inert atmosphere, and keep it warm for ...

Embodiment 3

[0032] A preparation method of a sodium ion capacitor having both high energy density and high power density, comprising the following steps:

[0033] Step 1, the specific surface area is 1800m 2 / g, the pore volume is 1.4cm 3 / g of porous carbon, mixed with conductive carbon black (superP), and binder PVDF according to the mass ratio of 75:10:15, and the organic solvent NMP (mass ratio of porous carbon: 4:1) was added to obtain the positive electrode slurry. The positive electrode slurry is coated on the aluminum foil, and after drying, rolling and punching, the positive electrode sheet of the sodium ion capacitor, that is, the porous carbon electrode sheet is obtained.

[0034]Step 2, fully mix 2 mg / ml graphene oxide ultrasonic dispersion with 2 mg / ml few-layer molybdenum disulfide ultrasonic dispersion, the volume ratio of graphene and molybdenum disulfide dispersion is 1:19. After fully mixing, dry at 180°C, heat to 800°C under an inert atmosphere, and keep it warm for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com