Method using liquid chromatography to analyze purity of solid sodium dimethyl dithiocarbamate

A technology of liquid chromatography and formex, which is applied in the field of instrument analysis, can solve the problems of impurity peaks not being detected, peak shape not sharp enough, main peak peak low, etc., to reduce or eliminate peak tailing phenomenon, normal peak, peak shape sharp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

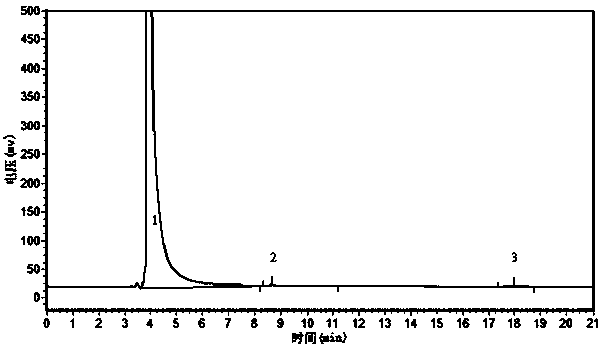

Embodiment 1

[0032] 1. Instrument:

[0033] (1) FL2200 liquid chromatograph with UV detector, N2000 chromatographic workstation

[0034] (2) Column Kromstar C18 4.6×250mm 5μm

[0035] (3) Constant temperature column box: Ripley RPL-C2000

[0036] (4) Ultrasonic degassing device.

[0037] 2. Detection conditions:

[0038] (1) Mobile phase: a. 50mmol / L sodium dihydrogen phosphate solution (containing 0.05% tetrabutylammonium chloride by volume fraction). b. Methanol (chromatographic grade). Mobile phase ratio V a :V b =60:40;

[0039] (2) Detection wavelength: 260nm (determined by a diode array detector)

[0040] (3) Flow rate: 0.8mL / min

[0041] (4) Injection volume: 20μL

[0042] (5) Column temperature: 30°C.

[0043] 3. Sample processing:

[0044] Accurately weigh 0.01g of sodium dimethyldithiocarbamate, dissolve it with mobile phase a, set the volume in a 100mL volumetric flask, filter it through an aqueous membrane, and degas it for later use.

[0045] 4. Detection steps: ...

Embodiment 2

[0053] 1. Instrument:

[0054] (1) FL2200 liquid chromatograph with UV detector, N2000 chromatographic workstation

[0055] (2) Column Kromstar C18 4.6×250mm 5μm

[0056] (3) Constant temperature column box: Ripley RPL-C2000

[0057] (4) Ultrasonic degassing device.

[0058] 2. Detection conditions:

[0059] (1) Mobile phase: a. 50mmol / L sodium dihydrogen phosphate solution (containing 0.05% tetrabutylammonium chloride by volume fraction). b. Acetonitrile (chromatographic grade). Mobile phase ratio V a :V b =70:30;

[0060] (2) Detection wavelength: 260nm (determined by a diode array detector)

[0061] (3) Flow rate: 0.8mL / min

[0062] (4) Injection volume: 20μL

[0063] (5) Column temperature: 30°C.

[0064] 3. Sample processing:

[0065] Accurately weigh 0.01g of sodium dimethyldithiocarbamate, dissolve it with mobile phase a, set the volume in a 100mL volumetric flask, filter through an aqueous membrane, and degas it for later use.

[0066] 4. Detection steps:

...

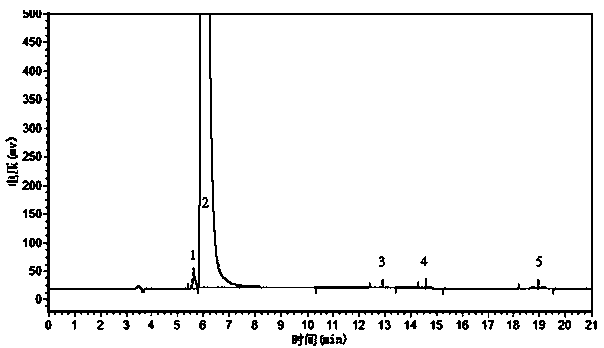

Embodiment 3

[0075] 1. Instrument:

[0076] (1) FL2200 liquid chromatograph with UV detector, N2000 chromatographic workstation

[0077] (2) Column Kromstar C18 4.6×250mm 5μm

[0078] (3) Constant temperature column box: Ripley RPL-C2000

[0079] (4) Ultrasonic degassing device.

[0080] 2. Detection conditions:

[0081] (1) Mobile phase: a. 50mmol / L sodium dihydrogen phosphate solution (containing 0.05% tetrabutylammonium chloride by volume); b. Acetonitrile (chromatographically pure);

[0082] Mobile phase ratio V a :V b =70:30, then add 0.2ml of chromatographically pure triethylamine as a pH regulator and tail remover. The addition amount of chromatographically pure triethylamine is mobile phase V a with mobile phase V b two thousandths of the sum of volumes;

[0083] (2) Detection wavelength: 260nm (determined by a diode array detector)

[0084] (3) Flow rate: 0.8mL / min

[0085] (4) Injection volume: 20μL

[0086] (5) Column temperature: 30°C.

[0087] 3. Sample processing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com