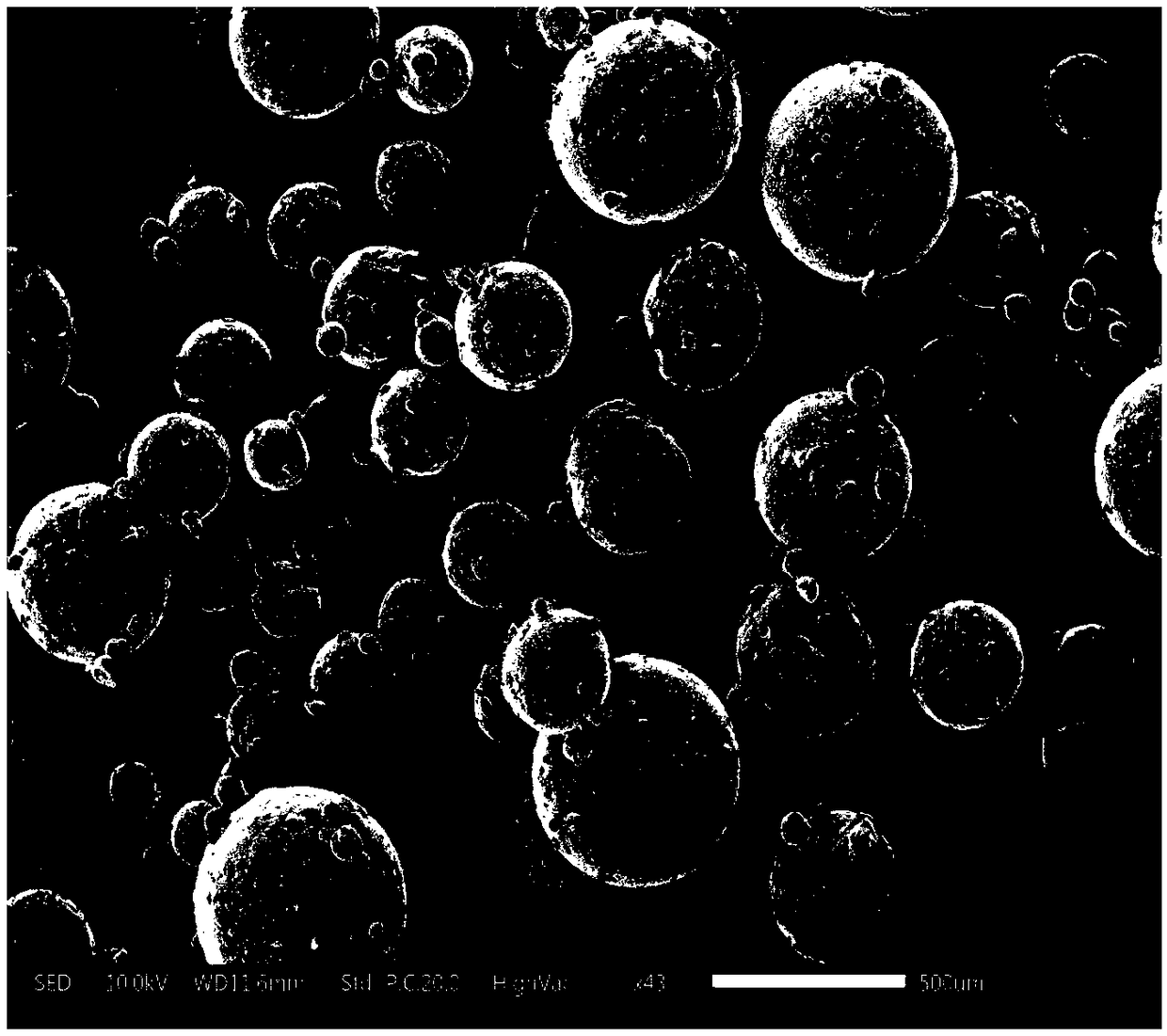

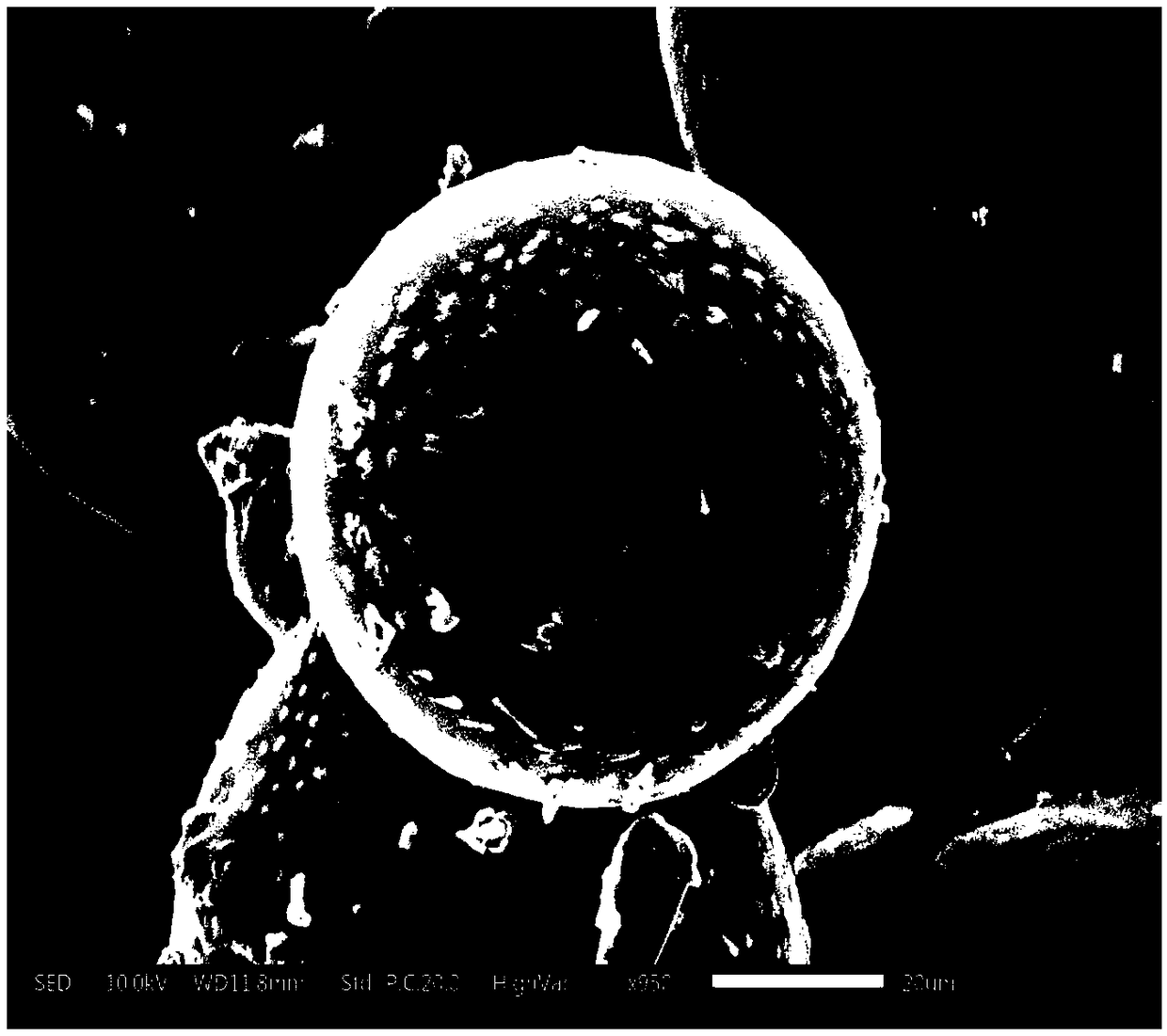

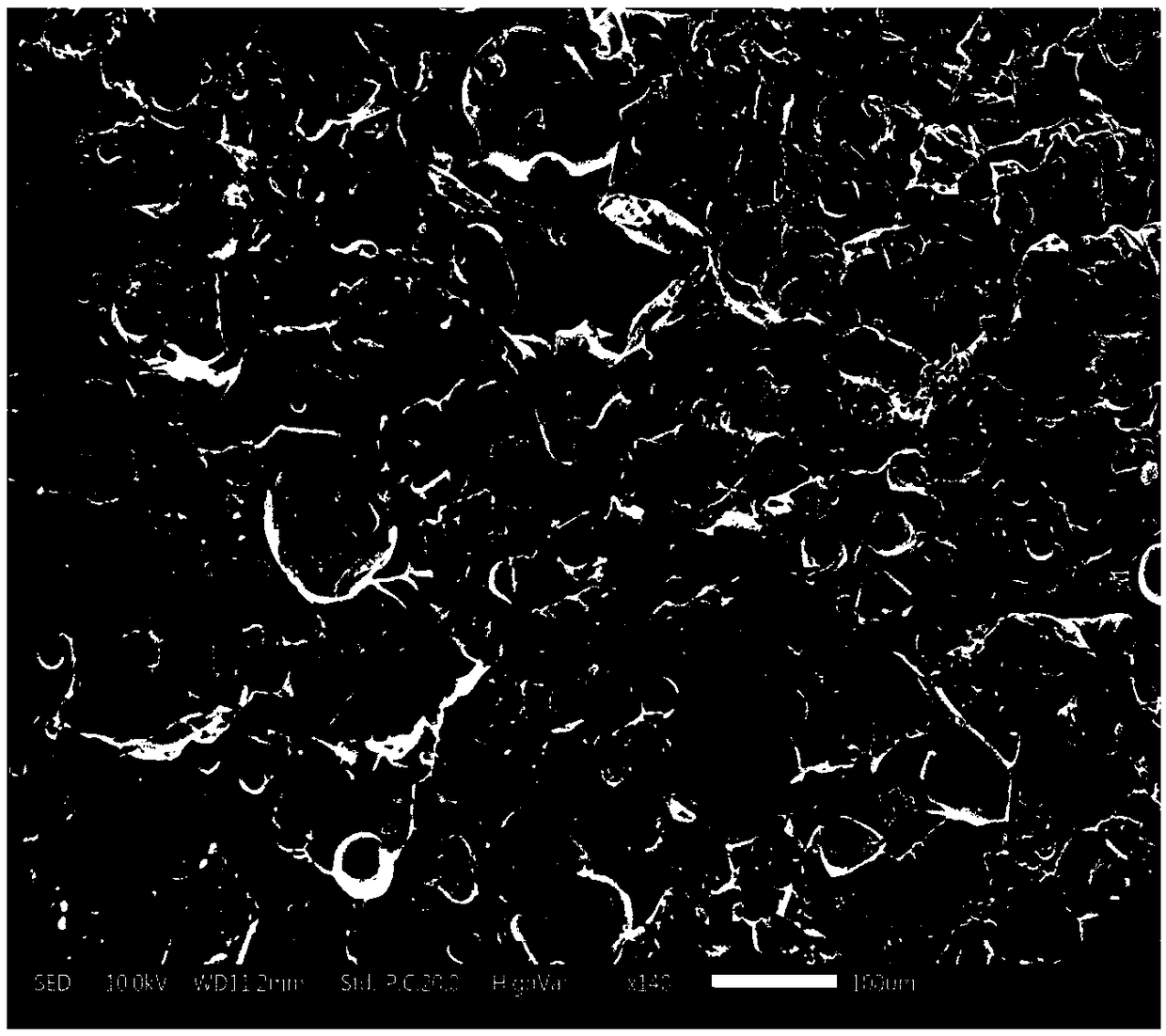

Method for preparing modified cyclodextrin based porous microspheres

A cyclodextrin and microsphere technology, applied in the field of polymer microsphere synthesis, can solve the problems of difficult removal of oil and other impurities in the separation process, cumbersome post-processing, complex system, etc., and achieves low production cost, versatility, separation Handling simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Take 10g of β-cyclodextrin in a three-necked flask, add 40mL of 0.04mol / L NaOH solution, and basify with magnetic stirring in a water bath at 60°C for 0.5h; then add 24g of sodium chloroacetate, and continue to stir magnetically in a water bath at 60°C After 1 hour, use 6mol / L hydrochloric acid to adjust the pH of the solution to 7, then pour at least 5 times the volume of absolute ethanol into the solution and stir quickly until a large amount of white precipitate is produced, and then keep the solution in cold storage for 12 hours. The solution was subjected to suction filtration, and the solid obtained by suction filtration was washed with absolute ethanol and then vacuum-dried to obtain carboxymethyl-β-cyclodextrin.

[0022] (2) Take 5g of carboxymethyl-β-cyclodextrin in a beaker, add 29.12g of NaOH solution with a mass fraction of 35%, stir magnetically at 60°C until carboxymethyl-β-cyclodextrin is dissolved, and then add 6g Add polyethylene glycol 600, then ad...

Embodiment 2

[0029](1) Take 11g of β-cyclodextrin in a three-neck flask, add 45mL of 5mol / L NaOH solution, and alkalinize it with magnetic stirring in a water bath at 60°C for 0.5h; then add 31g of sodium chloroacetate, and continue stirring for 1h under a water bath at 60°C Use 6mol / L hydrochloric acid to adjust the pH of the solution to 7, then pour at least 5 times the volume of absolute ethanol into the solution and stir it quickly until a large amount of white precipitate is produced, then put the solution in a refrigerator for 12 hours, and refrigerate the processed solution Suction filtration is carried out, and the solid obtained by suction filtration is washed with absolute ethanol and then vacuum-dried to obtain carboxymethyl-β-cyclodextrin.

[0030] (2) Take 10g of carboxymethyl-β-cyclodextrin in a beaker, add 60.3g of NaOH solution with a mass fraction of 35%, stir magnetically at 60°C until carboxymethyl-β-cyclodextrin is dissolved, and then add 12g Polyethylene glycol 600, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com