A method and integrated device for in-situ electrochemical oxidation-reduction conditioning sludge

An in-situ electrochemical and sludge technology, applied in electrochemical sludge treatment, chemical instruments and methods, sludge treatment, etc., can solve problems such as reducing sludge conditioning effect, achieve simple operation, good conditioning effect, improve effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

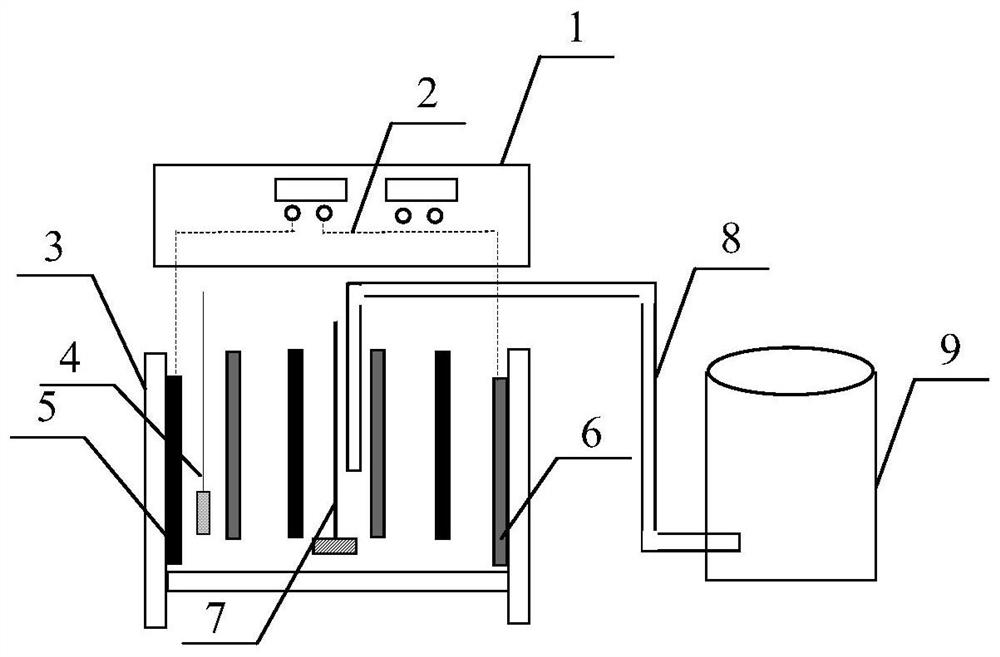

Image

Examples

Embodiment 1

[0037] The remaining sludge in the secondary sedimentation tank of a sewage treatment plant in Jinhua City has a moisture content of 98.1% and a pH value of 7.6. The sludge is placed in the sludge tank area of the electrochemical in-situ electrochemical oxidation-reduction reactor, and hydrochloric acid is added. Adjust the pH to 6.8. Prepare a 10mol / L calcium chlorate solution, and add the calcium chlorate solution to the sludge tank under sufficient stirring conditions to make the molar concentration 3mmol / gVSS. Turn on the power and react under stirring conditions for 30 minutes; turn off the power and add 50 mg / L of polyacrylamide and react under stirring conditions of 100 rpm for 3 minutes; then react under stirring conditions of 50 rpm for 15 minutes. The conditioned sludge is transported to a belt filter press for dehydration, and the moisture content of the mud cake is 59.7%.

Embodiment 2

[0039] Sludge from a printing and dyeing factory in Suzhou City has a moisture content of 97.3% and a pH value of 5.7. The sludge is placed in the sludge tank of an electrochemical in-situ electrochemical oxidation-reduction reactor. Prepare a mixed solution of 6mol / L sodium chlorate and potassium manganate, wherein the molar ratio of sodium chlorate and potassium manganate is 3:1, and add sodium chlorate and manganic acid into the sludge tank under sufficient stirring conditions Potassium mixed solution, so that its molar concentration is 2mmol / g VSS. Turn on the power and react under stirring conditions for 20 minutes; turn off the power, add polyacrylamide 75 mg / L, react under stirring conditions of 120 rpm for 3 minutes; then react under stirring conditions of 40 rpm for 20 minutes. The conditioned sludge is transported to a plate and frame filter press for dehydration, and the moisture content of the mud cake is 56.2%.

Embodiment 3

[0041]The remaining sludge in the secondary sedimentation tank of a sewage treatment plant in Cangzhou City, the sludge moisture content is 98.9%, and the pH value is 7.2. The sludge is placed in the sludge tank area of the electrochemical in-situ electrochemical oxidation-reduction reactor, and sulfuric acid is added. Adjust the pH to 6.5. Prepare a mixed solution of 7mol / L magnesium chlorate and calcium chlorite, wherein the molar ratio of magnesium chlorate and calcium chlorite is 1:1, and under sufficient stirring conditions, add magnesium chlorate and calcium chlorite to the sludge tank The mixed solution of calcium chlorite has a molar concentration of 4mmol / g VSS. Turn on the power, and react for 50 minutes under stirring conditions; turn off the power, add 250 mg / L polyacrylamide, and react for 4 minutes under stirring conditions of 80 rpm; then react for 30 minutes under stirring conditions of 50 rpm. The conditioned sludge is transported to a stacked screw centrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com