Blending system and mixing process of isoprene rubber and brominated butyl rubber

A technology of brominated butyl rubber and isoprene rubber, which is applied in the field of rubber, can solve the problems of self-sealing performance and degradation of rubber shavings produced by rubber stoppers, and achieve stable mixing curves, good rubber dispersion, and The effect of excellent vulcanization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

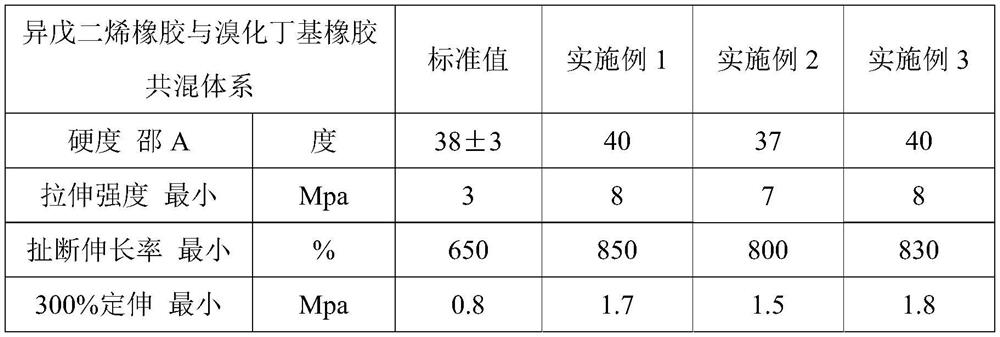

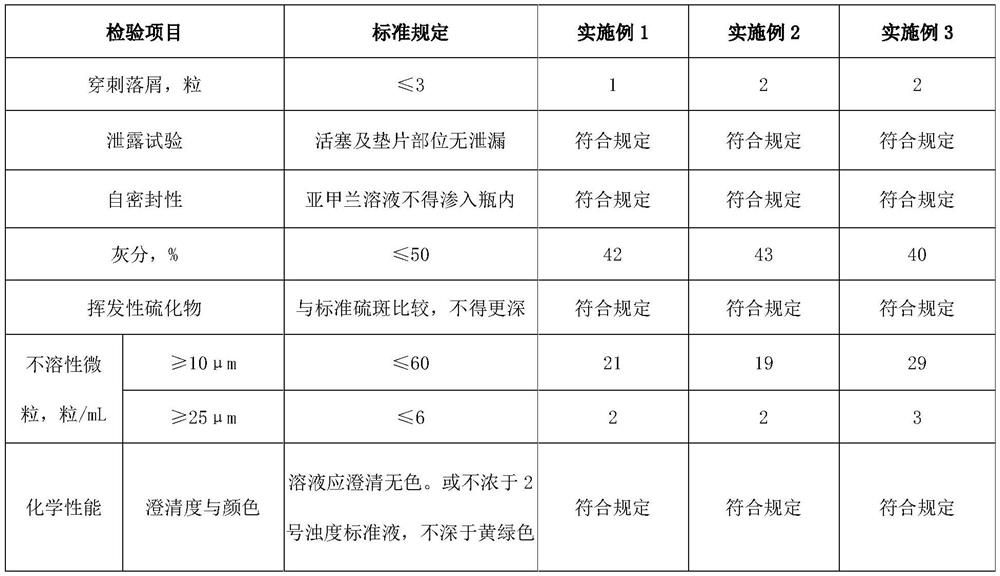

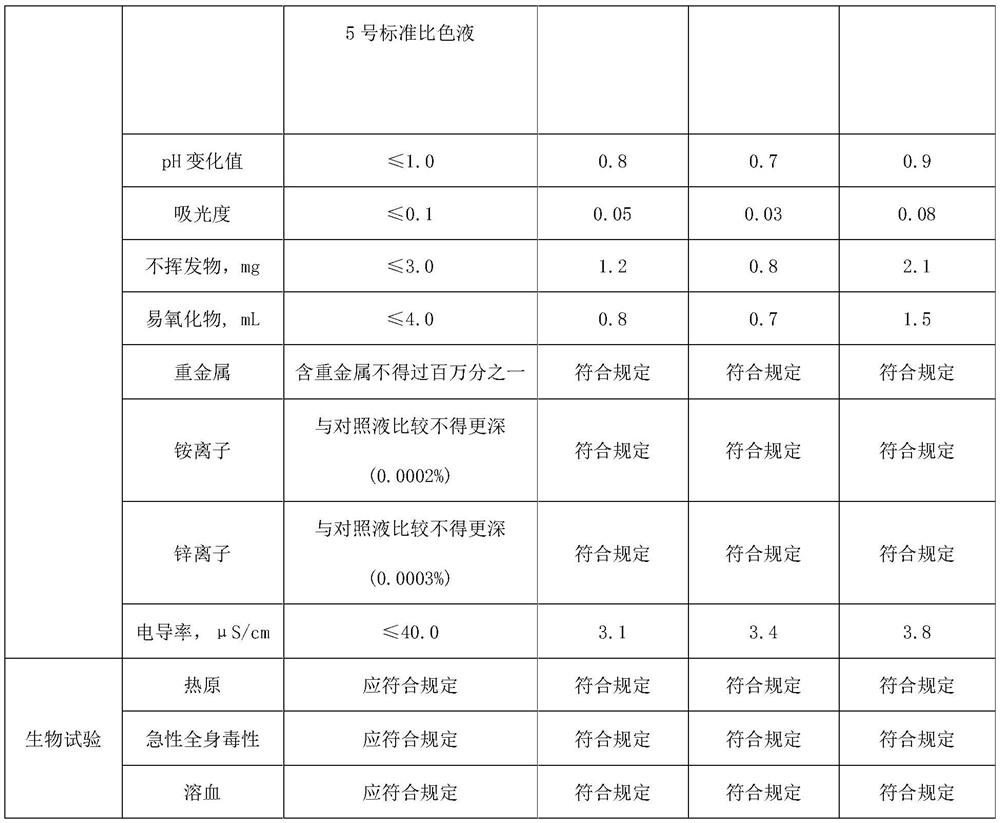

Examples

Embodiment 1

[0026] Masterbatch: bromobutyl rubber 2.5kg, titanium dioxide 1kg, reinforcing agent carbon black 0.02kg, vulcanizing agent phenolic resin 2.5kg;

[0027] Mixed rubber: bromobutyl rubber 17.5kg, isoprene rubber 30kg, clay 37.5kg, softener modified polyethylene 0.5kg and stearic acid 0.75kg, accelerator zinc oxide 2.5kg, antioxidant 1076 0.5 kg.

[0028] A mixing process of a blend system of isoprene rubber and bromobutyl rubber, the concrete process steps are as follows:

[0029] (1) Firstly, the bromobutyl rubber in the masterbatch is pressed and kneaded with titanium dioxide, reinforcing agent and vulcanizing agent until the rubber is discharged at 90°C to produce the masterbatch;

[0030] (2) In the process of mixing raw rubber and masticating, first add brominated butyl rubber and then put it into pottery clay, and carry out 2 minutes of pressing and banburying;

[0031] (3) drop into isoprene rubber, softener, promotor, antioxidant in step (2) again and carry out 2min c...

Embodiment 2

[0036] Masterbatch: bromobutyl rubber 1.875kg, titanium dioxide 0.5kg, reinforcing agent carbon black 0.01kg, vulcanizing agent phenolic resin 2kg;

[0037] Mixed rubber: bromobutyl rubber 13.125kg, isoprene rubber 25kg, clay 32.5kg, softener modified polyethylene 0.4kg and stearic acid 0.6kg, accelerator zinc oxide 2kg, antioxidant 1076 0.4kg .

[0038] A mixing process of a blend system of isoprene rubber and bromobutyl rubber, the concrete process steps are as follows:

[0039] (1) Firstly, the bromobutyl rubber in the masterbatch is pressed and kneaded with titanium dioxide, reinforcing agent and vulcanizing agent until the rubber is discharged at 90°C to produce the masterbatch;

[0040] (2) In the process of mixing raw rubber and masticating, first add brominated butyl rubber and then put it into pottery clay, and carry out 2 minutes of pressing and banburying;

[0041] (3) drop into isoprene rubber, softener, promotor, antioxidant in step (2) again and carry out 2min ...

Embodiment 3

[0046] Masterbatch: bromobutyl rubber 3.125kg, titanium dioxide 1.5kg, reinforcing agent carbon black 0.03kg, vulcanizing agent phenolic resin 3kg;

[0047] Mixed rubber: bromobutyl rubber 21.875kg, isoprene rubber 35kg, clay 42.5kg, softener modified polyethylene 0.6kg and stearic acid 0.9kg, accelerator zinc oxide 3kg, antioxidant 1076 0.6kg .

[0048]A mixing process of a blend system of isoprene rubber and bromobutyl rubber, the concrete process steps are as follows:

[0049] (1) Firstly, the bromobutyl rubber in the masterbatch is pressed and kneaded with titanium dioxide, reinforcing agent and vulcanizing agent until the rubber is discharged at 90°C to produce the masterbatch;

[0050] (2) In the process of mixing raw rubber and masticating, first add brominated butyl rubber and then put it into pottery clay, and carry out 2 minutes of pressing and banburying;

[0051] (3) drop into isoprene rubber, softener, promotor, antioxidant in step (2) again and carry out 2min c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com