High efficiency heat dissipation power amplifier manufacturing method and heat dissipation cabinet

A technology of a power amplifier and a manufacturing method, which is applied in cooling/ventilation/heating transformation, chassis/cabinet/drawer parts, electrical equipment structural parts, etc. High resistance, inability to spread the power amplifier chip, etc., to achieve the effect of reducing grounding resistance, reducing weight and volume, and reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make it easier for those skilled in the art to understand the technical solution of this patent, and at the same time, in order to make the technical purpose, technical solution and beneficial effect of this patent clearer, and to fully support the protection scope of the claims, the following is a specific case in the form of this patent. The technical solution of the patent makes further and more detailed descriptions.

[0031] A method for manufacturing a high-efficiency heat dissipation power amplifier, comprising the following steps:

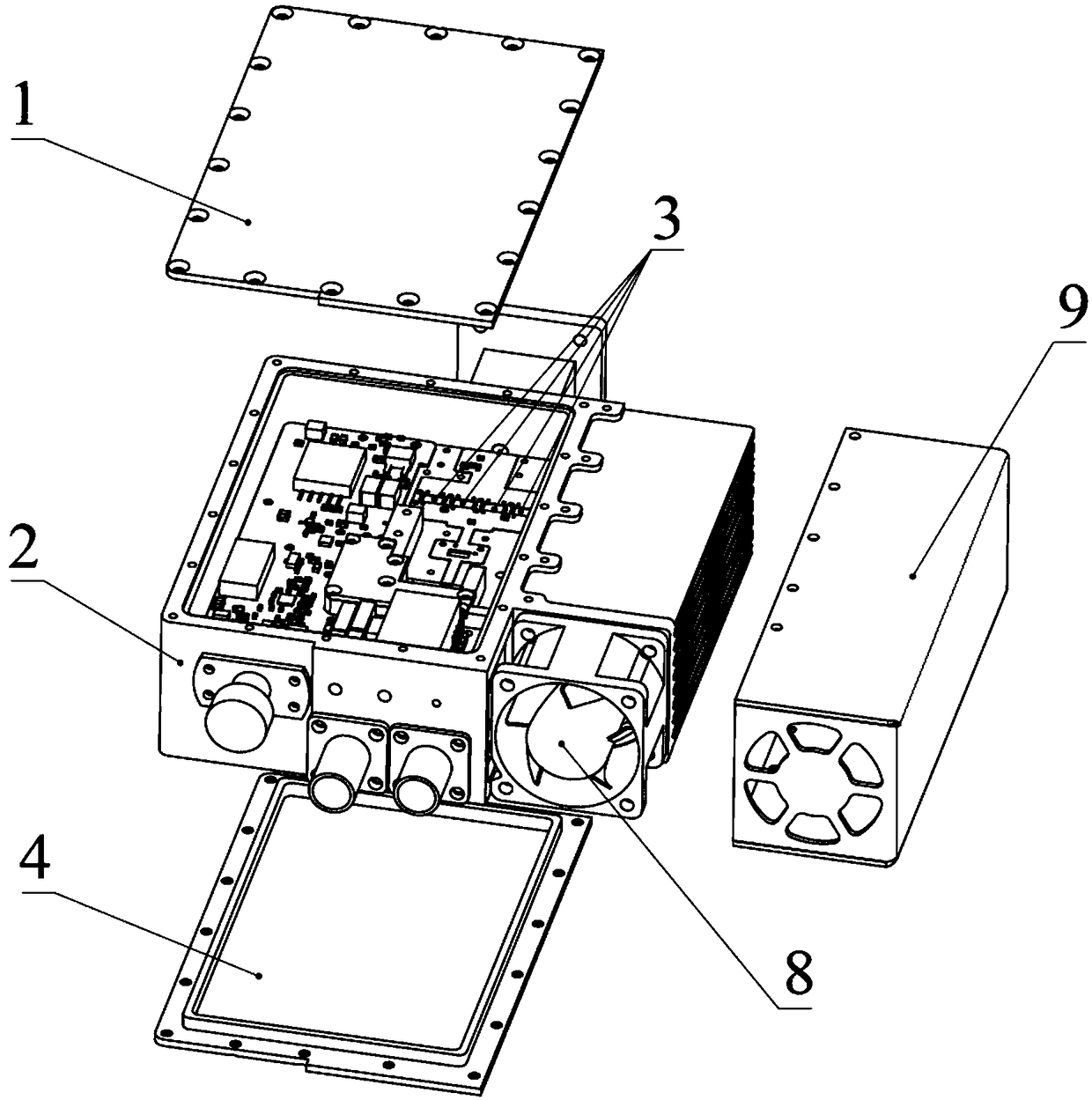

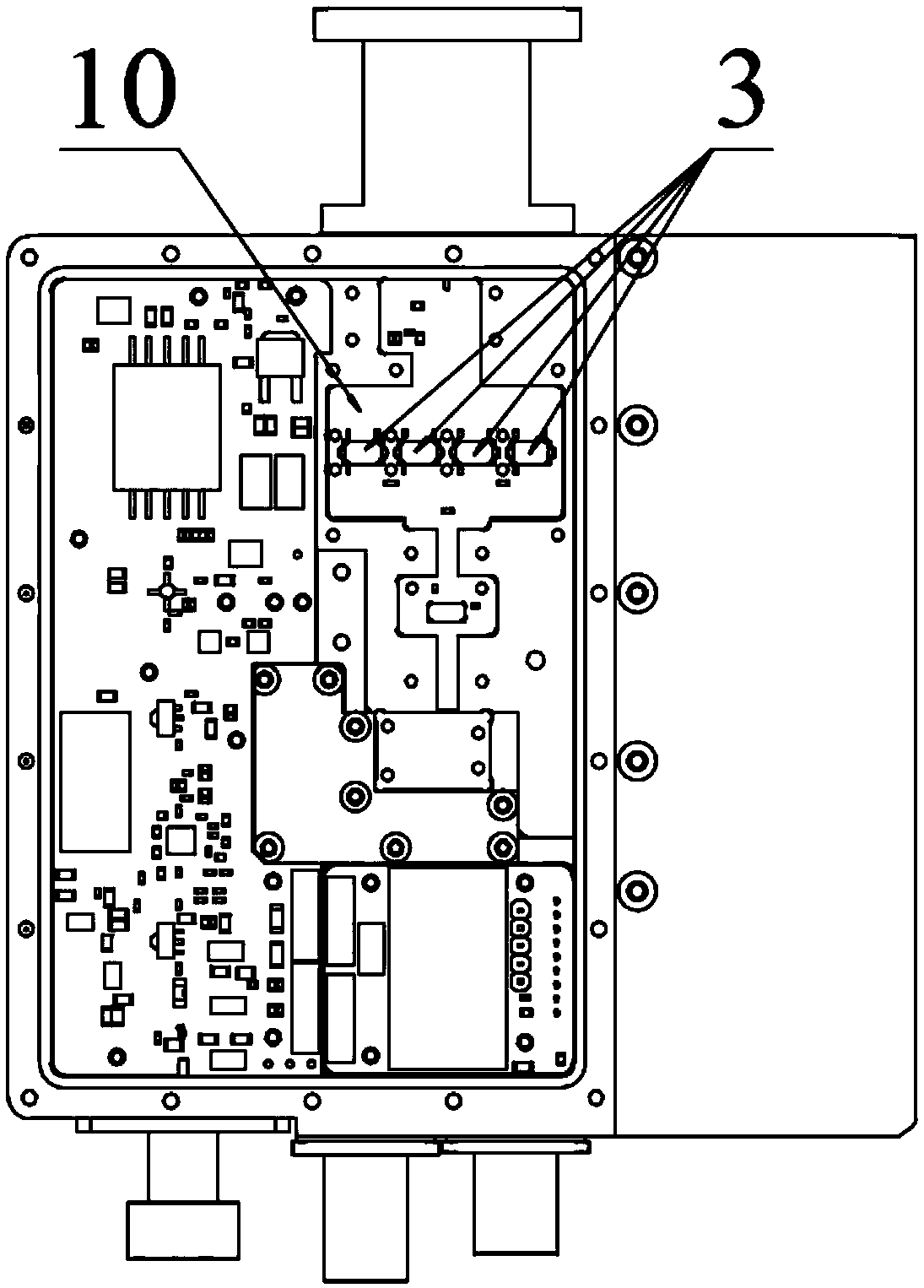

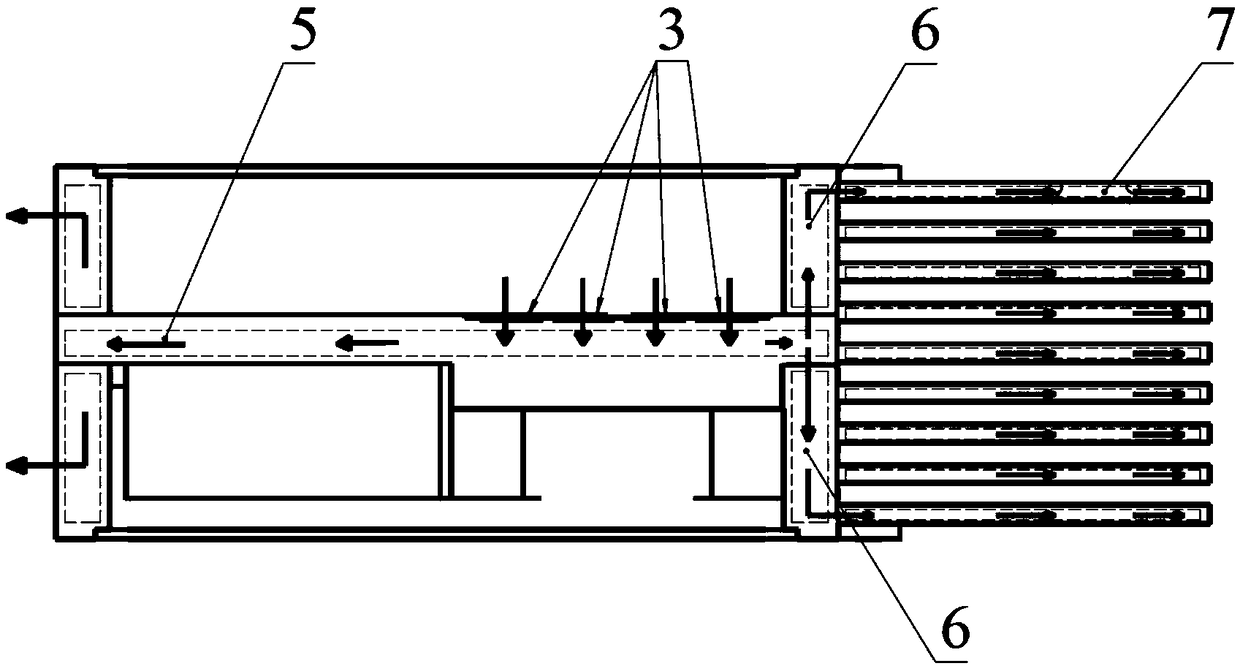

[0032] (1) Prepare the plate as the box wall and heat dissipation fins, weld the box wall to form a heat dissipation chassis, and weld the heat dissipation fins to the outside of the heat dissipation chassis; there are one or more device cavities inside the heat dissipation chassis, and at least one device cavity is a power amplifier Cavity;

[0033] (2) Mill one or more chip mounting slots on the bottom wall of the powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com