Liquid surface tension coefficient measuring device

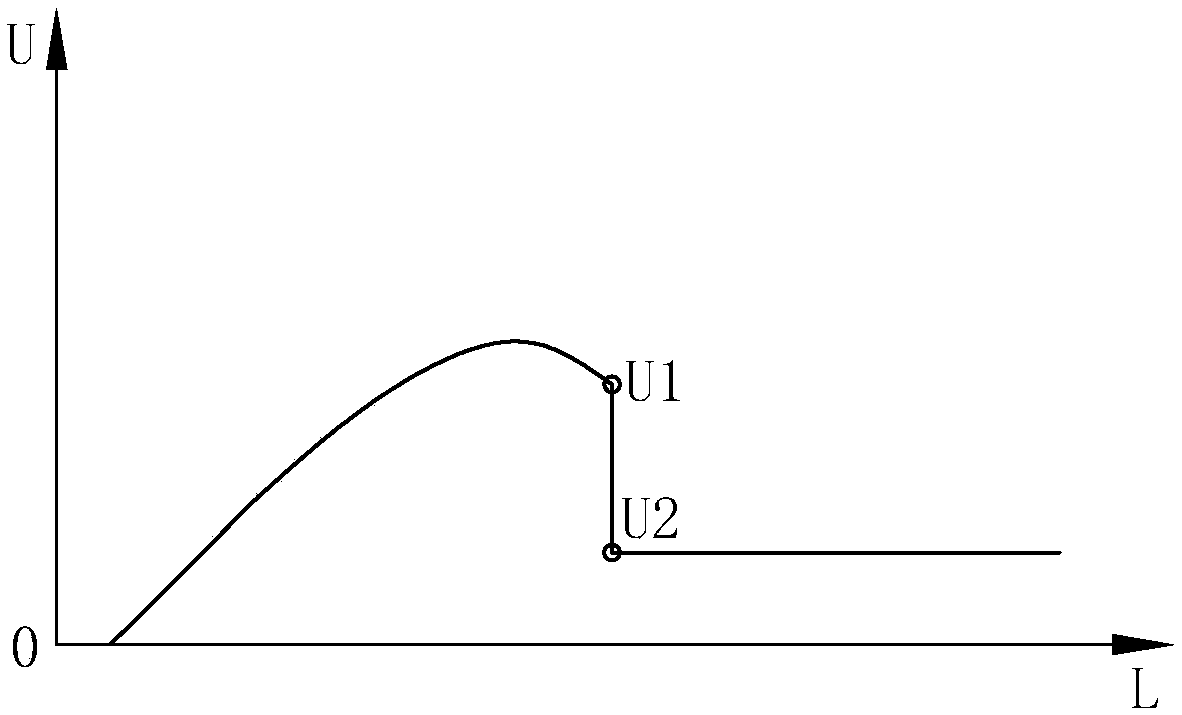

A liquid surface tension and measuring device technology, applied in the field of physics teaching experiments, can solve the problems of difficult observation of tension variation, inaccurate measurement, small calculation error, etc., to avoid premature rupture of liquid film, ensure measurement accuracy, and measure accurately Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0020] like figure 1 , 2 As shown, a liquid surface tension coefficient measuring device includes a suspension ring 1 and a base 4 , wherein the suspension ring 1 is hoisted on a force-sensitive sensor 2 , the force-sensitive sensor 2 is mounted on a bracket 3 , and the bracket is fixedly mounted on the base 4 . The bracket 3 is a "ten" shape structure, and the force sensitive sensor 2 is installed on the horizontal section.

[0021]Just below the suspension ring 1 is provided a petri dish 5 for containing the liquid to be tested, and the petri dish 5 is a glass vessel. The petri dish 5 is placed on an externally purchased heating sheet 6, and the heating sheet 6 is installed on the top surface of the placement platform 7. When the heating sheet 6 is energized, it can heat the liquid in the petri dish 5, thereby adjusting the temperature of the liquid in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com