Dynamic crosslinking double-network water gel as well as preparation method and application thereof

A dynamic cross-linking and double-network technology, applied in the fields of pharmaceutical formulations, medical science, prostheses, etc., can solve the problems of cytotoxicity, low mechanical, thermal, chemical stability, rejection, etc., and achieve simple preparation methods and excellent mechanics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

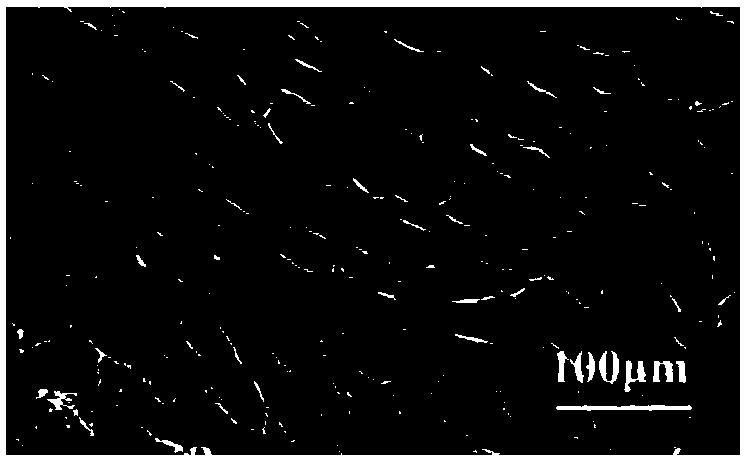

[0049] Embodiment 1, preparation of hydroxyethyl chitosan / calcium alginate dynamic cross-linked double network hydrogel

[0050]Prepare mixed solution 1 of 20mg / ml hydroxyethyl chitosan and 20mg / ml calcium chloride, prepare mixed solution 2 of 20mg / ml CHO-PEG-CHO and 20mg / ml sodium alginate, mix mixed solution 1 and mixed solution 2 Mix and stir at room temperature, mix and inject into a special mold to obtain a dynamic cross-linked double network hydrogel, which is released from the mold after 5 minutes to obtain a regular columnar body, which is the dynamic cross-linked double network hydrogel of hydroxyethyl chitosan / calcium alginate. The network hydrogel is subjected to a mechanical compression test on a universal testing machine, and the compressive stress is 0.12MPa, and the fracture deformation rate is 52%.

[0051] Prepare a 20mg / ml hydroxyethyl chitosan solution and a 20mg / ml CHO-PEG-CHO solution, mix them and inject them into the mold, and release them from the mold ...

Embodiment 2

[0059] Example 2, Preparation of Hydroxyethyl Chitosan / Calcium Alginate Dynamically Crosslinked Double Network Hydrogel

[0060] Prepare mixed solution 1 of 40mg / ml hydroxyethyl chitosan and 20mg / ml calcium chloride, prepare mixed solution 2 of 40mg / ml CHO-PEO-CHO and 20mg / ml sodium alginate, mix mixed solution 1 and mixed solution 2 Mix and stir at room temperature, mix and inject into a special mold to obtain a dynamic cross-linked double network hydrogel, demould from the mold after 5 minutes to obtain a regular columnar body, perform a mechanical compression test on a universal testing machine, and obtain a compressive stress of 0.23MPa, The fracture deformation rate was 54%.

Embodiment 3

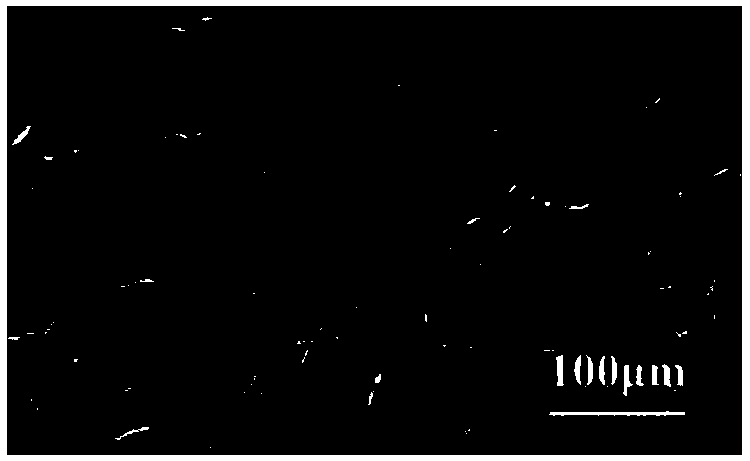

[0061] Example 3, Preparation of polyvinylamine / iron polyacrylate dynamically cross-linked double network hydrogel

[0062] Prepare a mixed solution 1 of 20mg / ml polyvinylamine and 20mg / ml ferric chloride, prepare a mixed solution 2 of 20mg / ml CHO-PEG-CHO and 20mg / ml polyacrylic acid, mix the mixed solution 1 and the mixed solution 2 and let it cool at room temperature Stir, mix and pour into a special mold to obtain a dynamic cross-linked double network hydrogel. After 5 minutes, it is demolded from the mold to obtain a regular columnar body. The mechanical compression test is carried out on a universal testing machine, and the compressive stress is 0.08MPa, and the fracture deformation rate is 0.08MPa. 75%.

[0063] Prepare a 20mg / ml polyvinylamine solution and a 20mg / ml CHO-PEG-CHO solution, mix them and inject them into the mold, release them from the mold after 5 minutes to obtain a regular columnar body, perform a mechanical compression test on a universal testing machin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive stress | aaaaa | aaaaa |

| Compressive stress | aaaaa | aaaaa |

| Compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com