Modulus modifier, preparation method and application thereof

A regulator and modulus technology, applied in the direction of offensive equipment, non-explosive/non-thermal agent components, explosives, etc., can solve the problems of low elongation rate of propellant and unsatisfactory elongation rate, and achieve effective and controllable sequence structure , Improve the modulus and strength, and the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

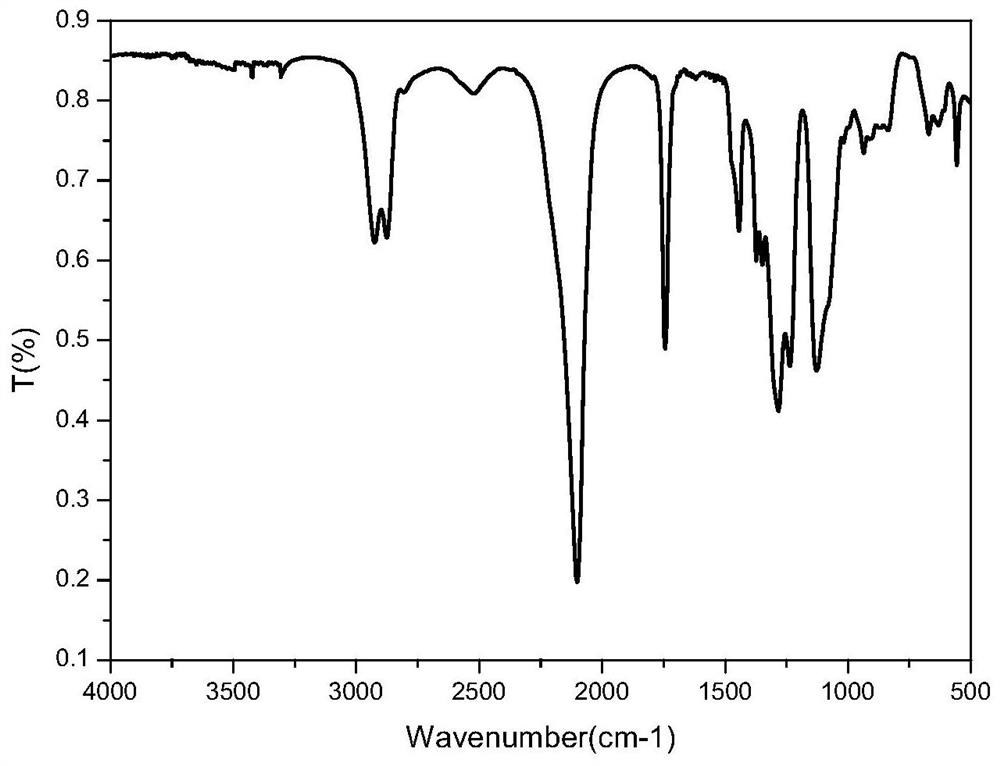

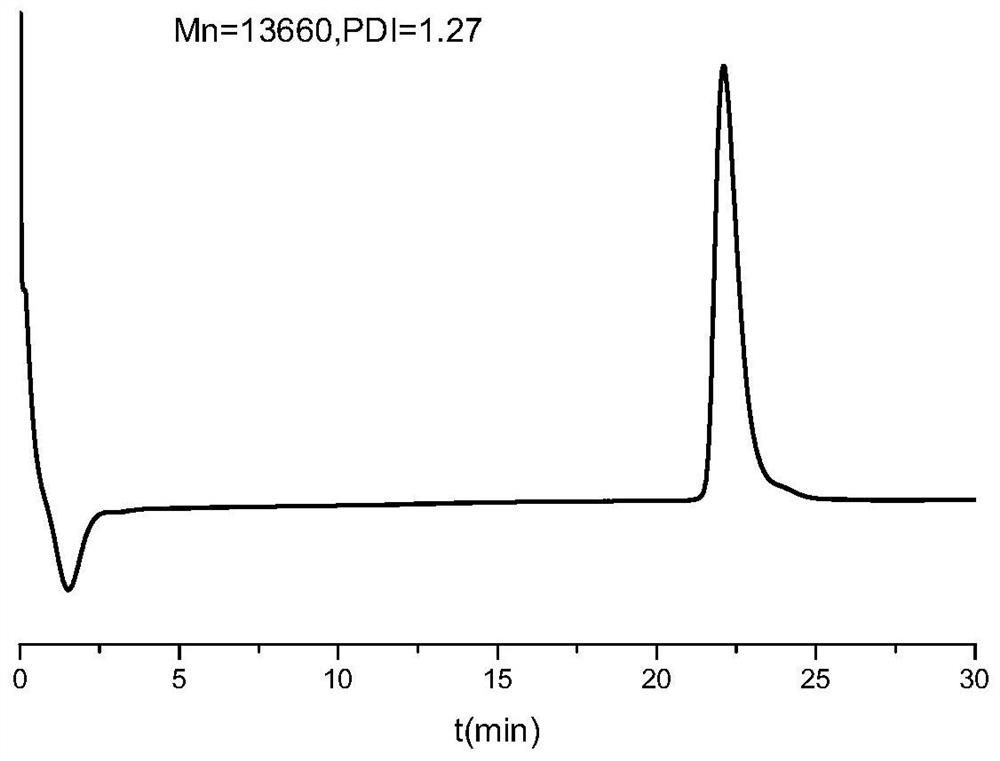

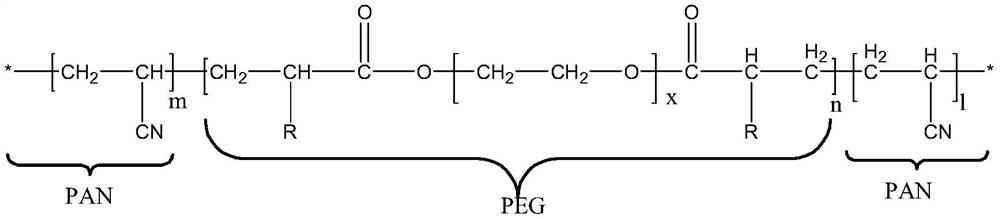

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of modulus regulator of the present invention specifically comprises the steps:

[0042](1) According to the ratio of substances, add 1,000 to 10,000 parts of solvent and 1 to 10 parts of free radical initiator in the reaction vessel, stir and dissolve to obtain a mixed solution; the solvent is methanol, ethanol, ethyl acetate or methyl acetate One or a mixture of any two; the free radical initiator is one of azobisisobutyronitrile AIBN or dibenzoyl peroxide BPO.

[0043] (2) Add 10-1000 parts of acrylonitrile monomer and 1-10 parts of reversible addition-fragmentation transfer reagent RAFT to the mixed solution under nitrogen or inert gas atmosphere, and react at 40-90°C for 5-20 Hours; heating can use oil bath heating;

[0044] (3) Add 10 to 200 parts of polyethylene glycol diacrylate or polyethylene glycol dimethacrylate to the mixed solution in step (2), stir and dissolve, and lower the temperature of the mixed solution under nitrogen or an i...

Embodiment 1

[0055] Select a four-necked flask (2L) equipped with magnetic stirring, reflux condenser, thermometer and addition funnel, etc., add 500ml of ethyl acetate and 0.328g of azobisisobutyronitrile AIBN into the four-necked flask, stir and dissolve to obtain a mixed solution.

[0056] Add 21.2g of acrylonitrile monomer and 0.449g of CPDB to the mixed solution under nitrogen atmosphere, and heat the reaction in an oil bath at 75°C for 20 hours under the protection of argon.

[0057] 0.328g AIBN, 0.449g CPDB, and 21.2g acrylonitrile (molar ratio=1:1:400) were added thereto.

[0058] Add 40g of polyethylene glycol diacrylate (Mn=400, molar ratio (acrylonitrile:polyethylene glycol diacrylate)=400:100)) to the reaction solution, stir to dissolve, and store at 75°C under the protection of argon. The bath was left to react for 20 hours.

[0059] 21.2 g of acrylonitrile and 0.449 g of CPDB were added to the reaction vessel, and the reaction was continued for 20 hours in an oil bath at 75°...

Embodiment 2

[0068] Select a four-necked flask (2L) equipped with magnetic stirring, reflux condenser, thermometer and addition funnel, etc., add 500ml of methyl acetate and 0.485g of dibenzoyl peroxide BPO into the four-necked flask, stir and dissolve to obtain a mixed solution.

[0069] Add 26.5g of acrylonitrile monomer and 0.545g of CPDE to the mixed solution under nitrogen atmosphere, and heat in an oil bath at 55°C for 20 hours under the protection of argon.

[0070] 0.485g BPO, 0.545g CPDE, and 26.5g acrylonitrile (molar ratio=1:1:500) were added thereto.

[0071] Add 75g of polyethylene glycol dimethacrylate (Mn=750, molar ratio (acrylonitrile:polyethylene glycol diacrylate)=500:100)) to the reaction solution, in a 55°C oil bath under the protection of argon The reaction was continued for 20 hours.

[0072] 26.5 g of acrylonitrile and 0.545 g of CPDE were added to the reaction vessel, and the reaction was continued for 20 hours in an oil bath at 55° C. under the protection of argo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com