Method for preparing high thermal conductivity aluminum nitride powder based on graphene

A graphene, high thermal conductivity technology, applied in the field of preparation of high thermal conductivity aluminum nitride powder, can solve the problems of reducing the production capacity of the calciner, excessive volume expansion of the precursor, etc., and achieves high product performance, reduced oxygen content, and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

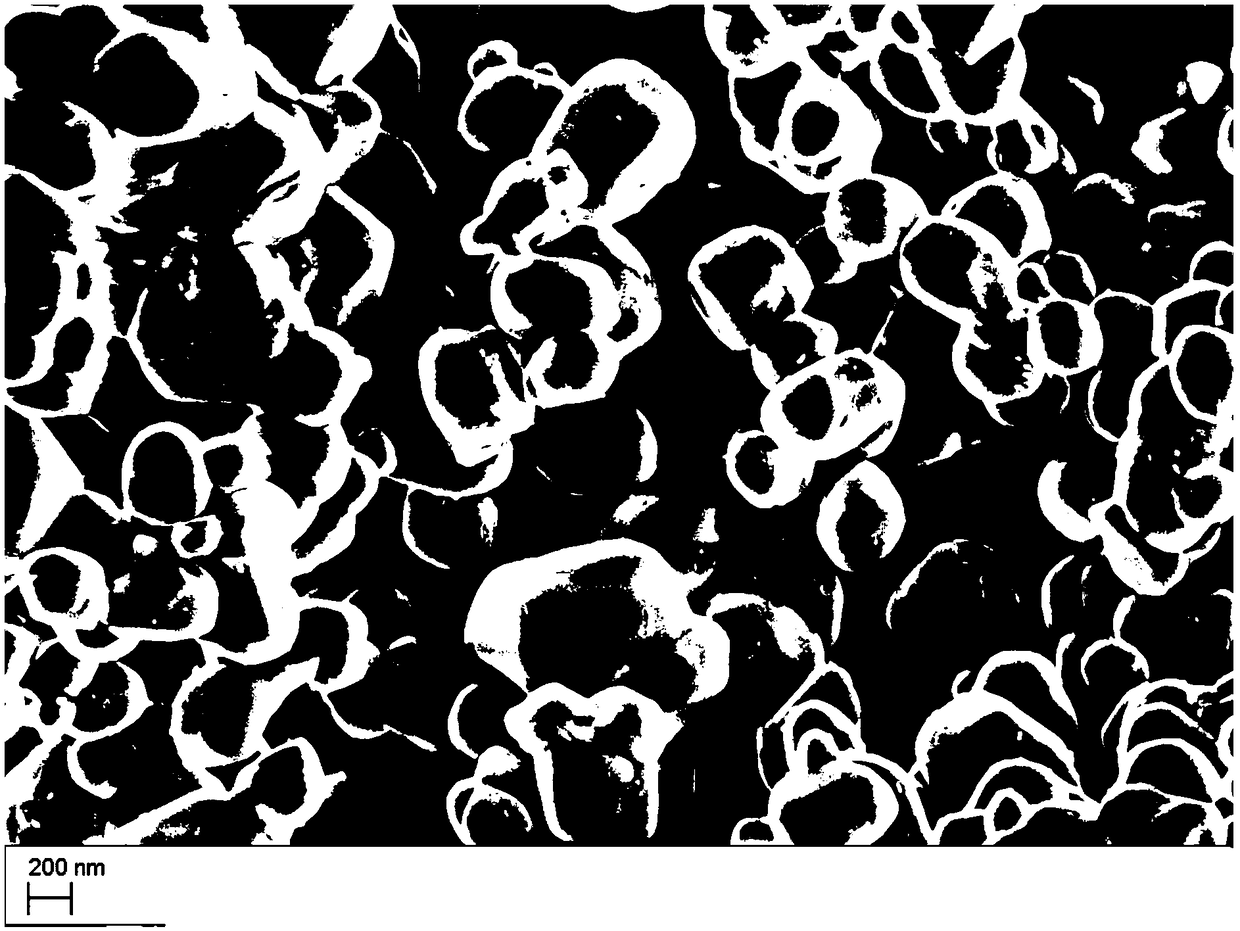

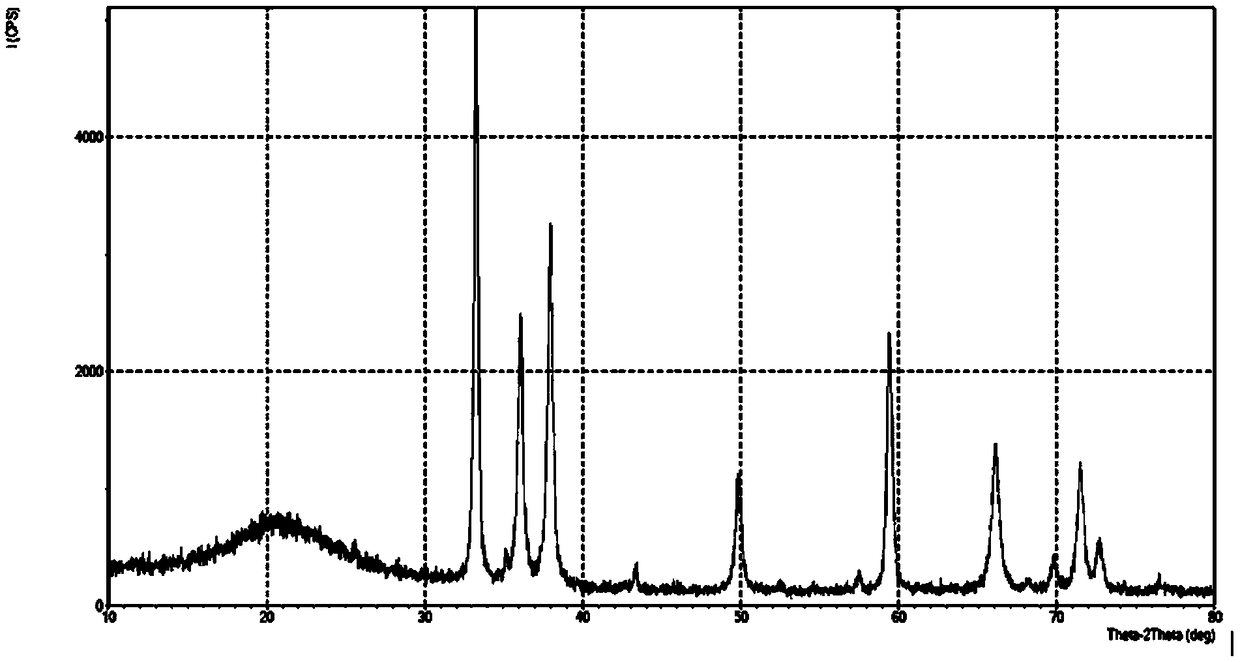

Image

Examples

Embodiment 1

[0025] Weigh 10 grams of γ-phase alumina and 4 grams of graphene, dry mix them, put them into a graphite crucible, put nitrogen into the tube furnace, raise the temperature to 1400 °C, keep the temperature for 3 hours and then cool down naturally, when the temperature drops to 1000 °C When the temperature is lower than ℃, a mixed gas of hydrogen and nitrogen is passed through, and the ventilation is maintained for 1 hour. When the temperature of the tube furnace drops to room temperature, take out the sample and put it into a corundum crucible. In an air atmosphere, program the temperature to 500°C and keep the temperature constant for 4 hours. After the sample is cooled, take it out to obtain aluminum nitride powder with high thermal conductivity.

Embodiment 2

[0027] Weigh 8 grams of α-phase alumina and 4 grams of graphene, dry mix them, put them into a graphite crucible, and feed ammonia gas into the tube furnace, program the temperature up to 2000°C, keep the temperature for 1 hour and then cool down naturally, when the temperature drops When the temperature reaches 1000°C, a mixed gas of carbon monoxide and nitrogen is passed through, and the ventilation is maintained for 1 hour. When the temperature of the tube furnace drops to room temperature, take out the sample and put it into a corundum crucible. In an air atmosphere, program the temperature to 800°C and keep the temperature constant for 0.5 hours. After the sample is cooled, take it out to obtain aluminum nitride powder with high thermal conductivity.

Embodiment 3

[0029] Weigh 3 grams of γ-phase alumina and 8 grams of graphene, dry mix them, put them into a graphite crucible, and feed ammonia gas into the tube furnace, program the temperature up to 1600°C, keep the temperature for 1 hour, and then cool down naturally. When the temperature reaches 1000°C, a mixed gas of hydrogen and helium is introduced, and the ventilation is maintained for 1 hour. When the temperature of the tube furnace drops to room temperature, take out the sample to obtain aluminum nitride powder with high thermal conductivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com