Method for extracting lithium from amblygonite and preparing iron-containing phosphate

A technology of lepidolite and phosphate, which is applied in the field of metal extraction and separation, can solve the problems of long process route, the extraction rate of lithium extraction needs to be improved, the lack of full utilization of lecithin, iron and phosphorus, etc., and achieves high purity. , the effect of low cost and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

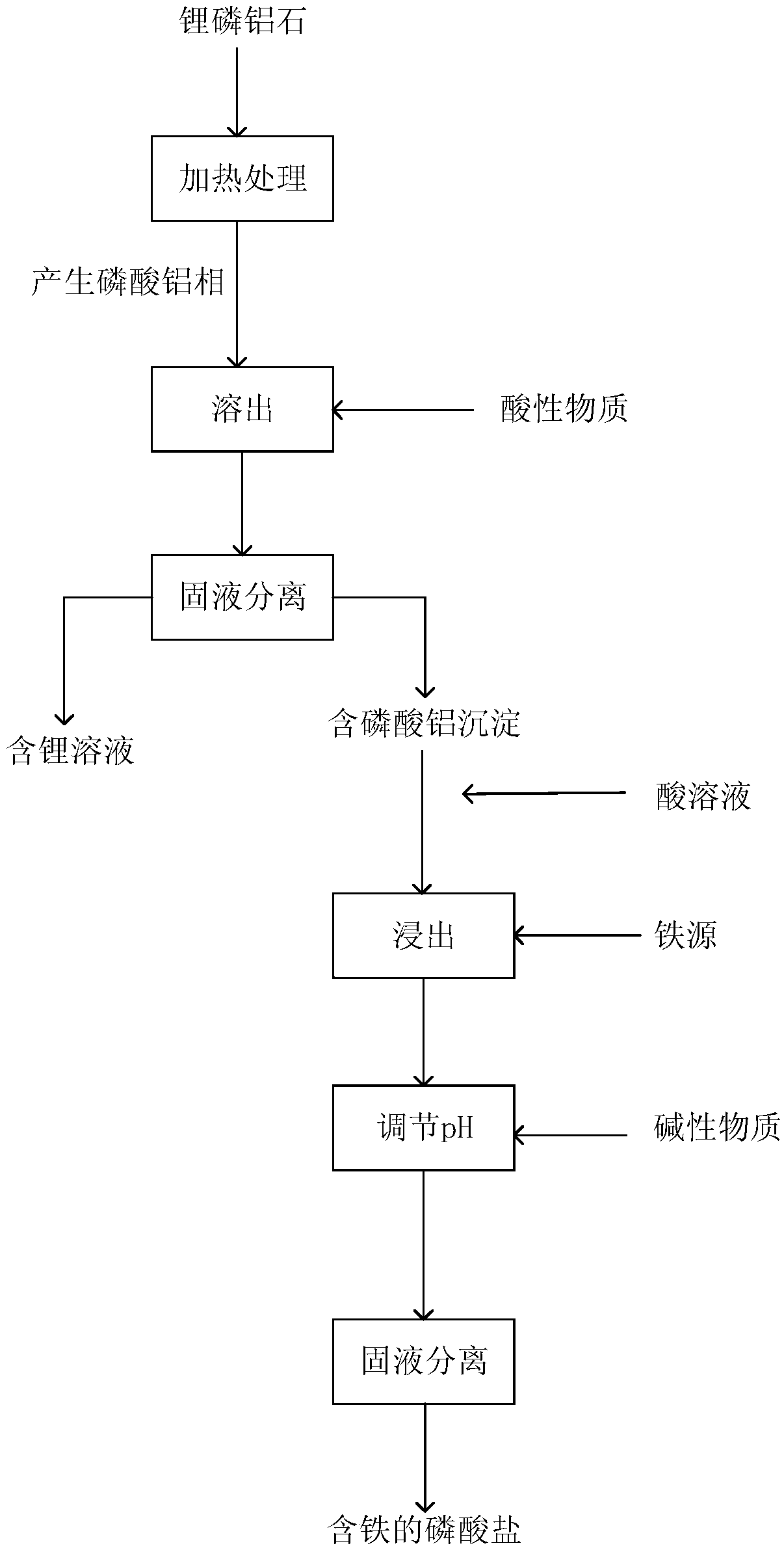

[0081] In this embodiment, lithium is extracted from lithium phosphate-diagenite and iron-containing phosphate is prepared according to the following method:

[0082] (1) Grinding and crushing the lithium phosphate-aluminite, and then roasting the lithium-phosphate-aluminite at 900°C for 3 hours in an air atmosphere to form an aluminum phosphate phase, and mixing the roasted lithium-phosphate-aluminite with ammonium sulfate at a mass ratio of 1:0.4 Lithium is dissolved out, the mixing temperature is 150° C., and the mixing time is 3 hours to obtain an eluate; the roasting is carried out in a muffle furnace;

[0083] (2) Filter and separate the stripping liquid described in step (1) to obtain a lithium-containing solution and an aluminum phosphate-containing precipitate, add ethanol to the lithium-containing solution, take the solid, and redissolve the solid in water to obtain purified Lithium-containing solution (the solute is lithium sulfate); the lithium-containing solution ...

Embodiment 2

[0091] In this embodiment, lithium is extracted from lithium phosphate-diagenite and iron-containing phosphate is prepared according to the following method:

[0092](1) Grinding and crushing the lithium phosphate-aluminite, and then roasting the lithium-phosphate-aluminite at 600°C for 6 hours in an air atmosphere to form an aluminum phosphate phase, and mixing the roasted lithium-phosphate-aluminite with hydrochloric acid at a mass ratio of 1:0.3 Lithium is dissolved out, the mixing temperature is 20°C, and the mixing time is 5h to obtain an eluate; the roasting is carried out in a muffle furnace;

[0093] (2) filter and separate the stripping solution described in step (1), obtain a lithium-containing solution and an aluminum phosphate-containing precipitate, carry out precipitation and impurity removal purification in the lithium-containing solution, and obtain a purified lithium-containing solution (the solute is hydrochloric acid Lithium); The lithium-containing solution...

Embodiment 3

[0098] In this embodiment, lithium is extracted from lithium phosphate-diagenite and iron-containing phosphate is prepared according to the following method:

[0099] (1) Sieve and crush the lithium phosphate aluminum phosphate, and then roast the lithium phosphate aluminum phosphate phase at 1100°C for 0.1h under a nitrogen atmosphere, and mix the roasted lithium phosphate and ammonium sulfate at a mass ratio of 1:0.5 Mixing is carried out to dissolve lithium, the mixing temperature is 300° C., and the mixing time is 13 hours to obtain an eluate; the roasting is carried out in a tube furnace;

[0100] (2) Filter and separate the stripping solution described in step (1) to obtain a lithium-containing solution and an aluminum phosphate-containing precipitate, add acetone to the lithium-containing solution, take the solid, and redissolve the solid in water to obtain purified Lithium-containing solution (the solute is lithium sulfate); the lithium-containing solution is crystalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com