Micro-textured negative plate for preliminary lithium supplementing and preparation method thereof

A technology of micro-textured and negative electrode sheet, which is applied in the field of micro-textured negative electrode sheet for pre-supplementing lithium and its preparation, which can solve the problems of battery stability, charge-discharge efficiency, discharge specific capacity reduction, easy formation of lithium dendrites, and high-capacity Problems such as volume expansion of negative electrode materials, to achieve the effect of compensating irreversible capacity, alleviating volume expansion, and improving first-time efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also proposes a method for preparing a micro-textured negative electrode sheet for pre-supplementing lithium, which has a short period of preparation for the negative electrode sheet, high efficiency, high precision, and strong controllability; including steps:

[0041]Step 1: Spin-coat an insulating photoresist layer 2 on the negative electrode current collector 1 after ultrasonic cleaning and vacuum drying, then perform soft baking, mask exposure, development, and hardening treatment on the photoresist layer 2, and then Prepare a pattern matching the microtexture on the surface of the photoresist layer 2 to obtain a negative electrode current collector 1 with an adhesive layer; wherein, the thickness of the photoresist layer 2 can be 0.5-10 μm;

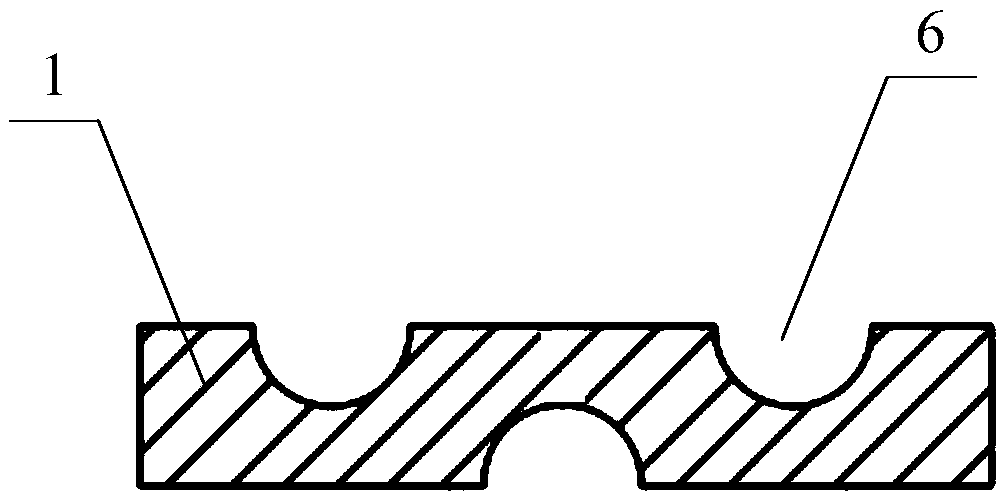

[0042] Step 2, using a dry etching process to prepare a micro-texture with a concave-convex structure on the surface of the negative electrode current collector 1 to obtain a micro-textured negative elect...

Embodiment 1

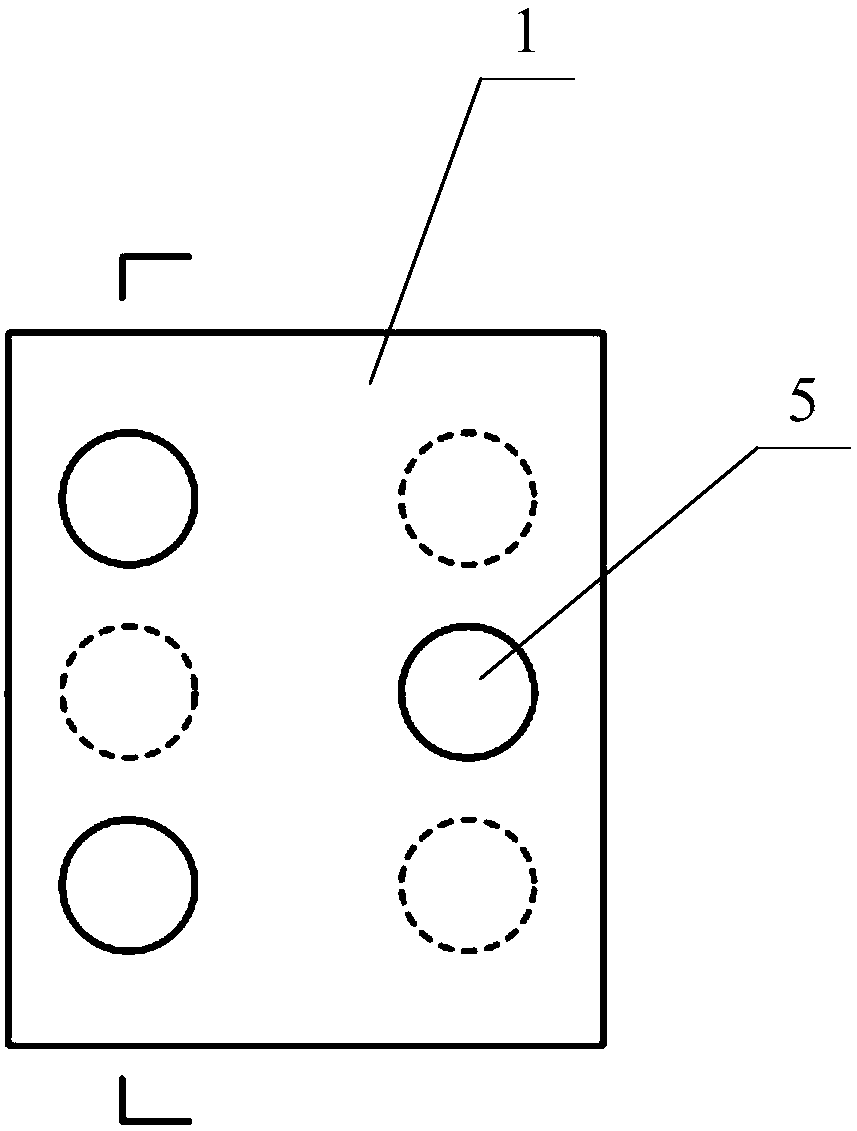

[0050] The preparation of the micro-textured negative electrode sheet with the cylindrical convex structure 5 pre-supplemented with lithium is carried out in sequence according to the following steps:

[0051] (1) The negative current collector 1 with a thickness of 16 μm is ultrasonically cleaned with acetone, ethanol and deionized water in sequence, and after vacuum drying, an insulating positive photoresist layer 2 is spin-coated thereon at a speed of 2000 r / min for 40 s; Soft-bake the photoresist layer 2 at 95°C for 12 minutes, expose the patterned mask for 6s, develop for 50s, and finally harden the film at 120°C for 4 minutes to prepare an etched columnar convex micro-texture on the surface of the photoresist layer 2 The desired pattern is obtained to obtain a negative electrode collector 1 with glue;

[0052] (2) Perform plasma etching treatment on the negative electrode current collector 1 with glue, the etching gas is hydrogen, the etching process is at a gas pressure...

Embodiment 2

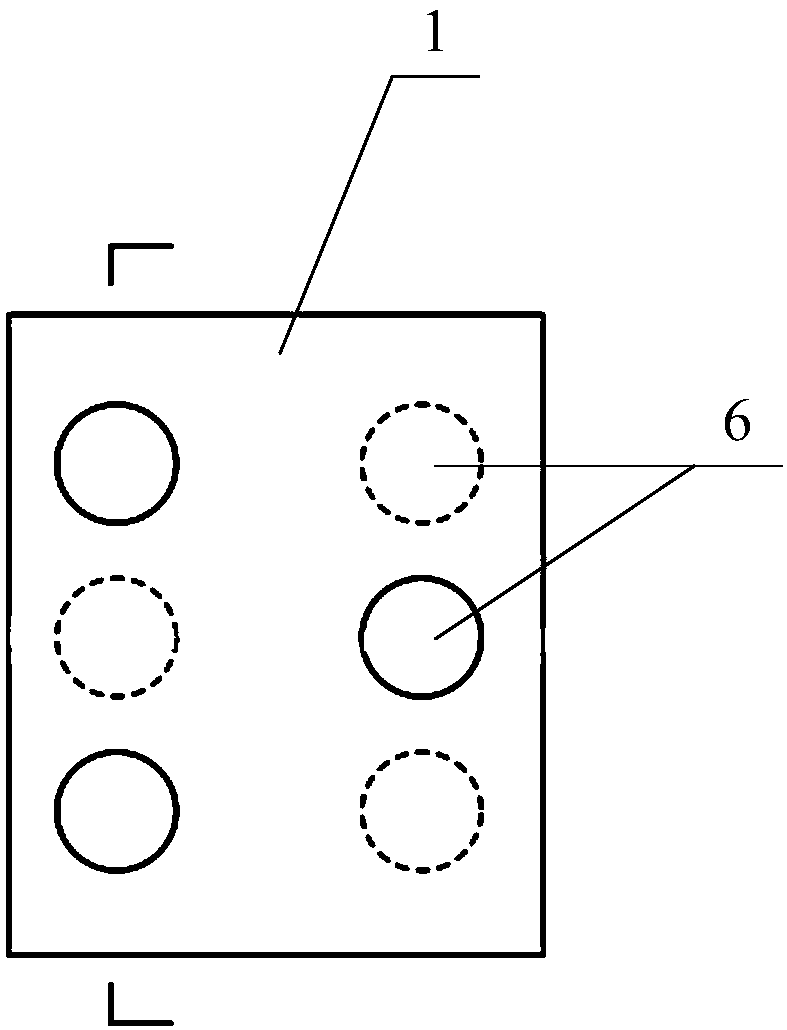

[0057] The preparation of the spherical concave structure 6 micro-textured negative electrode sheet with pre-supplemented lithium is carried out in sequence according to the following steps:

[0058] (1) The negative current collector 1 with a thickness of 15 μm is ultrasonically cleaned with acetone, ethanol and deionized water in sequence, and after vacuum drying, an insulating positive photoresist layer 2 is spin-coated on it at a speed of 2000 r / min for 40 s; Soft-bake the photoresist layer 2 at 100°C for 10 minutes, expose the patterned mask for 6s, develop for 40s, and finally harden the film at 120°C for 4 minutes to prepare an etched spherical pit micro-texture on the surface of the photoresist layer 2 The desired pattern is obtained to obtain a negative electrode collector 1 with glue;

[0059] (2) Perform plasma etching treatment on the negative electrode current collector 1 with glue, the etching gas is hydrogen, the etching process is at a gas pressure of 20mT, an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com