A long-term anti-corrosion and weather-resistant functional coating and its preparation method

A long-term anti-corrosion and coating technology, which is applied in the direction of anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of poor weather resistance and short anti-corrosion cycle, reduce porosity, facilitate operation, and reduce corrosion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The specific preparation process of the nano-titanium-based hybrid material in this example is as follows:

[0035] 1) Grinding aid configuration: Mix 40g of epoxy resin E51, 40g of sulfur-containing rubber LP-2 and 300g of acetone evenly as grinding aid;

[0036] 2) Grinding medium configuration: select wear-resistant steel balls with a particle size of Φ5mm, Φ15mm and Φ20mm, and mix them uniformly as grinding media with a mass of 100g, 150g and 1800g respectively;

[0037] 3) Preparation of titanium-based hybrid material: Weigh 500g of grinding aid, 2050g of grinding medium and 300g of micron titanium powder, place them in a wear-resistant alloy steel grinding jar, fix it on a high-energy ball mill with a rotation speed of 1800rpm, and ball mill at room temperature 3.5h, obtain the nano-titanium-based hybrid material in the shape of black slurry;

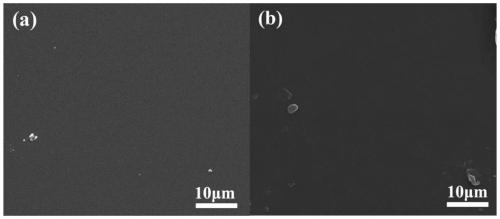

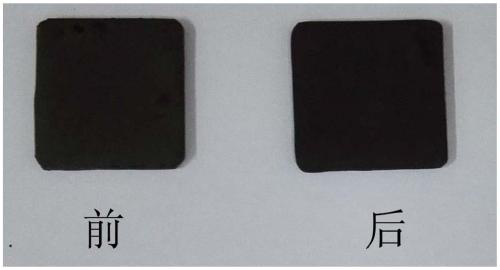

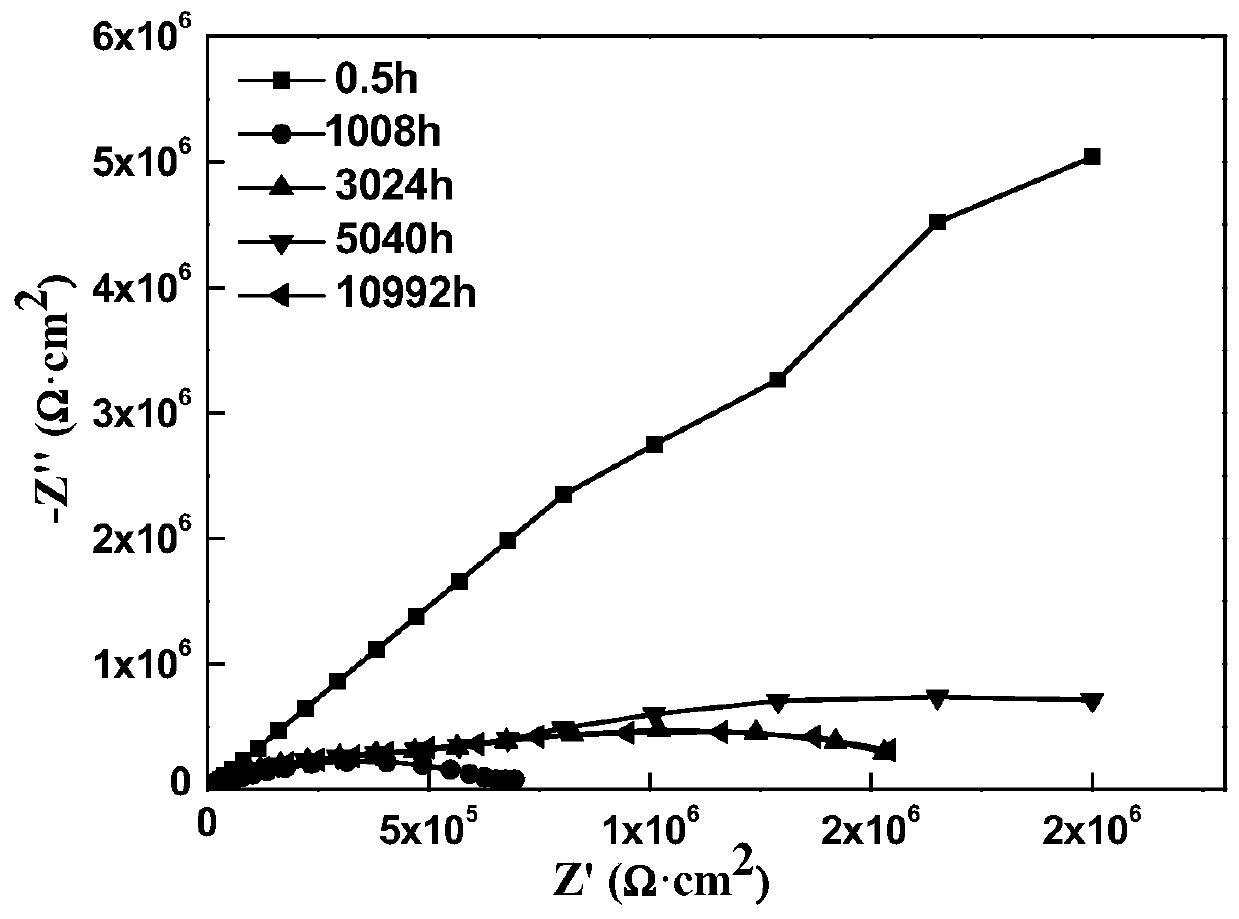

[0038] Compared with the infrared spectrum results of the nano-titanium-based hybrid material processed in Example 1 and...

Embodiment 2

[0040] The specific preparation process of the nano-titanium-based hybrid material in this example is as follows:

[0041] 1) Grinding aid configuration: Mix 45g of epoxy resin E51, 45g of sulfur-containing rubber LP-2 and 400g of acetone evenly as grinding aid;

[0042] 2) Grinding medium configuration: choose wear-resistant steel balls with a particle size of Φ5mm, Φ15mm and Φ20mm, and mix them uniformly as grinding media with a mass of 300g, 700g and 1600g respectively;

[0043] 3) Preparation of titanium-based hybrid material: Weigh 550g of grinding aid, 2600g of grinding medium and 500g of micron titanium powder, place them in a wear-resistant alloy steel grinding tank, fix it on a high-energy ball mill with a rotation speed of 1900rpm, and ball mill at room temperature 4h, obtain the nano-titanium-based hybrid material that becomes black slurry;

[0044] After grinding, it is the same as the result of Example 1, all being located at 914cm -1 The characteristic absorption...

Embodiment 3

[0046] The specific preparation process of the nano-titanium-based hybrid material in this example is as follows:

[0047] 1) Grinding aid configuration: mix 50g of epoxy resin E51, 50g of sulfur-containing rubber LP-2 and 450g of acetone evenly as grinding aid;

[0048] 2) Grinding medium configuration: select wear-resistant steel balls with a particle size of Φ5mm, Φ15mm and Φ20mm, and mix them uniformly as grinding media with a mass of 50g, 700g and 1900g respectively;

[0049] 3) Preparation of titanium-based hybrid material: Weigh 600g of grinding aid, 2650g of grinding medium and 550g of micron titanium powder, place them in a wear-resistant alloy steel grinding jar, fix it on a high-energy ball mill with a rotation speed of 1700rpm, and ball mill at room temperature 5h, obtain the nano-titanium-based hybrid material that becomes black slurry;

[0050] The epoxy bond breaks the bond, and the titanium atom is grafted with the epoxy bond, realizing the preparation of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| sedimentation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com