Intra-cavity pumped low internal heat solid-state laser system

A technology of solid-state lasers and pump light, applied in the field of lasers, can solve problems such as the inability to obtain lasers that suppress thermal effects, the inability to realize fluorescent cooling, and limited pump power, and achieve the effects of reducing thermal effects, compact structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

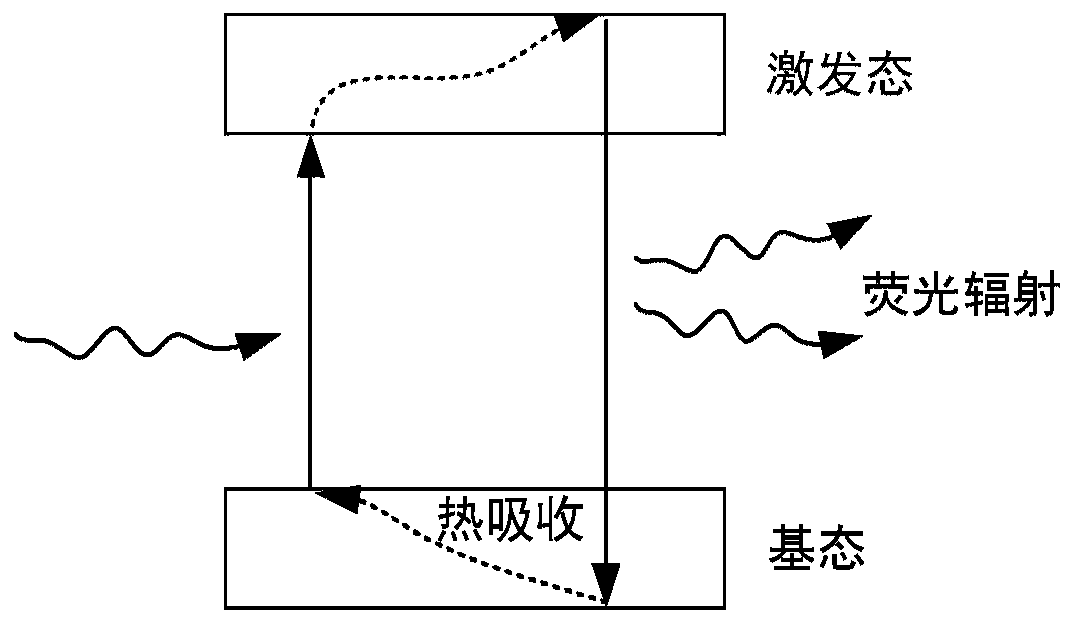

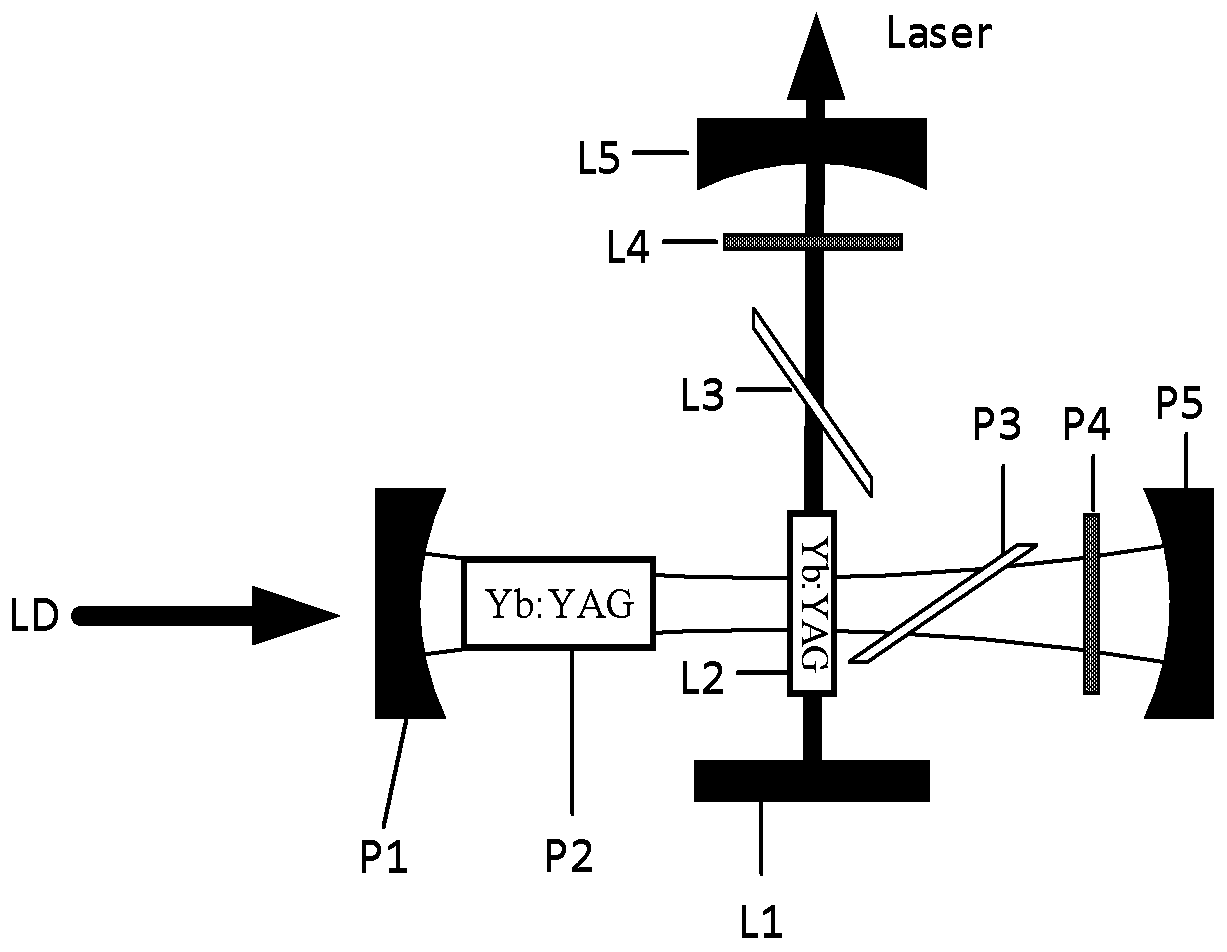

[0026] As mentioned above, the starting point of the present invention for the design of the intracavity pumped low internal heat solid-state laser system, that is, the low internal heat dual-cavity solid-state laser system, is to design a mechanism with a compact structure that can simultaneously obtain high laser power and long-wavelength pump light To meet the requirements of small, low-cost solid-state lasers in some applications, and to output high-power, high-quality lasers.

[0027] The intracavity pumped low internal heat solid-state laser system of the present invention, that is, the low internal heat dual-cavity solid-state laser system includes a long-wavelength pump light generation module, a long-wavelength pump light control module, a laser generation module, a laser adjustment module, and a laser output control module. module. By setting the gain medium in the laser generation module in the long-wavelength pump light oscillation path based on the long-wavelength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com