Preparation method of lithium nickel cobalt manganate for coated power battery.

A nickel-cobalt lithium manganese oxide and power battery technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems that the coating material reduces the specific capacity of the positive electrode material, the coating has obvious limitations, and the coating material is easy to fall off. , to achieve the effect of good coating stability, improved performance, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

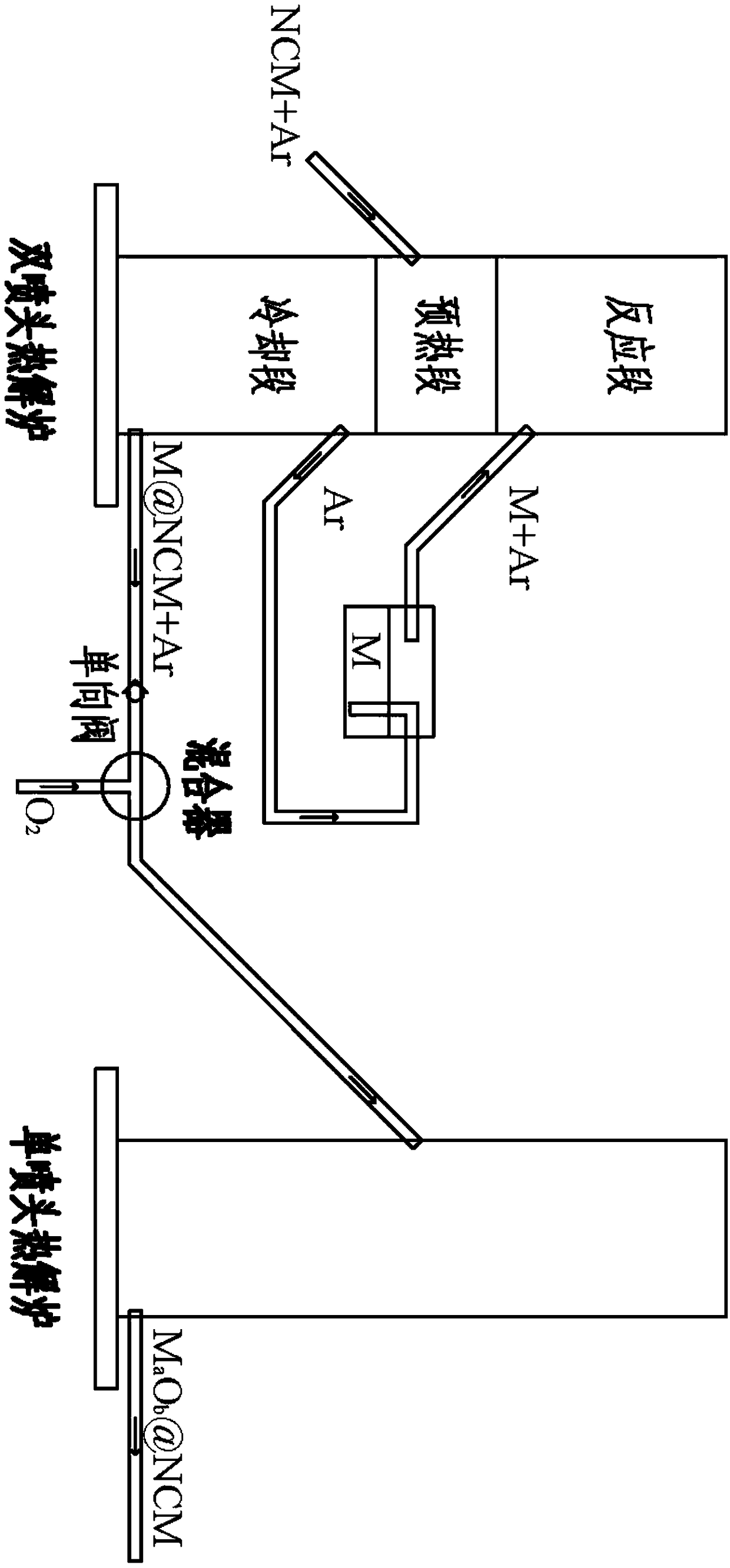

[0032] A preparation method of nickel-cobalt lithium manganese oxide for coated power batteries, comprising the following steps:

[0033] 1) preheating the nickel cobalt lithium manganese oxide particles;

[0034] 2) heating the metal to be coated to boiling under an inert gas atmosphere to obtain metal vapor;

[0035] 3) using an inert gas to blow the nickel cobalt lithium manganese oxide particles obtained by preheating in step 1) to the pyrolysis furnace, and simultaneously blowing the metal vapor obtained in step 2) to the pyrolysis furnace for reaction with an inert gas;

[0036] 4) The particles obtained after the reaction in step 3) are sent to the mixer through an inert gas, and mixed with an oxygen-containing mixed gas to form a solid-gas mixture;

[0037] 5) The solid-gas mixture is sent to a pyrolysis furnace for reaction to obtain a coated nickel-cobalt lithium manganate cathode material.

[0038] Preferably, in step 1) of the preparation method, the particle siz...

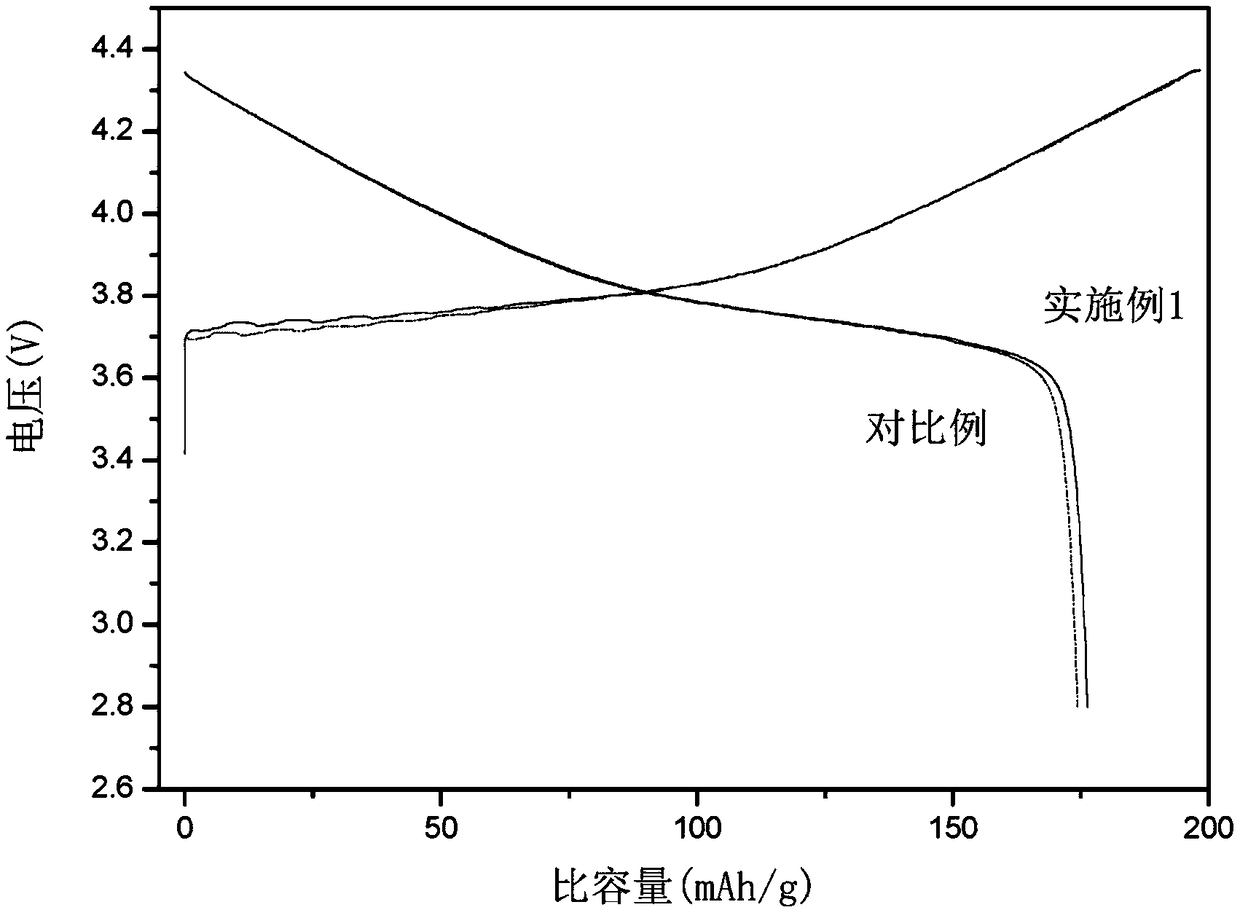

Embodiment 1

[0054] A preparation method of coated nickel-cobalt lithium manganese oxide comprises the following specific steps:

[0055] (1) It will be sintered once and crushed to particle size D 50 Preheat to 450 °C for 2 μm nickel cobalt lithium manganese oxide.

[0056] (2) Heat metal aluminum to boiling under argon atmosphere.

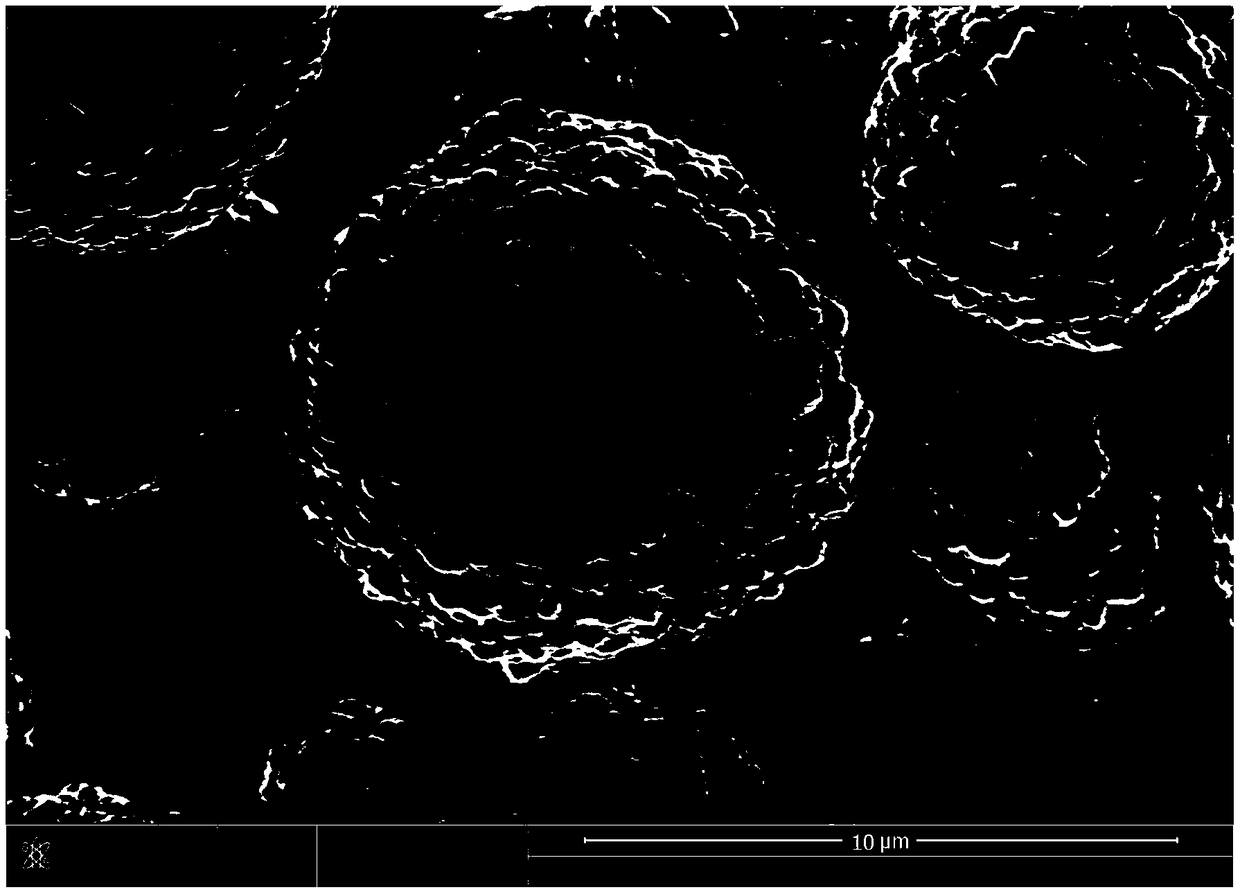

[0057] (3) Blow the preheated nickel-cobalt lithium manganese oxide (1) into the double nozzle pyrolysis furnace with argon gas, and at the same time blow the aluminum metal vapor obtained from (2) into the furnace from another nozzle with argon gas , the furnace temperature is controlled to be 500°C, the residence time of particles in the furnace is 1s, and the amount of metal coating (mass percentage in terms of metal elements) is controlled to be 0.05%.

[0058] (4) Gained particle is sent to mixer from double-nozzle pyrolysis furnace under argon atmosphere, and particle mixes with oxygen-argon gas mixture (oxygen concentration is 20ppm) in mixer before se...

Embodiment 2

[0064] A preparation method of coated nickel-cobalt lithium manganese oxide comprises the following specific steps:

[0065] (1) It will be sintered once and crushed to particle size D 50 Preheat the 10 μm nickel-cobalt-lithium manganese oxide to 800 °C.

[0066] (2) Metal magnesium is heated to boiling under an argon atmosphere.

[0067] (3) Blow the preheated nickel-cobalt lithium manganese oxide (1) into the double-nozzle pyrolysis furnace with argon gas, and simultaneously blow the magnesium metal vapor obtained from (2) into the furnace from another nozzle with argon gas , the furnace temperature is controlled to be 900° C., the residence time of particles in the furnace is 10 min, and the amount of metal coating (mass percentage in terms of metal elements) is controlled to be 0.1%.

[0068] (4) Gained particle is sent to mixer from double-nozzle pyrolysis furnace under argon atmosphere, and particle mixes with oxygen-argon gas mixture (oxygen concentration is 10ppm) in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com