Method for increasing recovery rate of shale gas

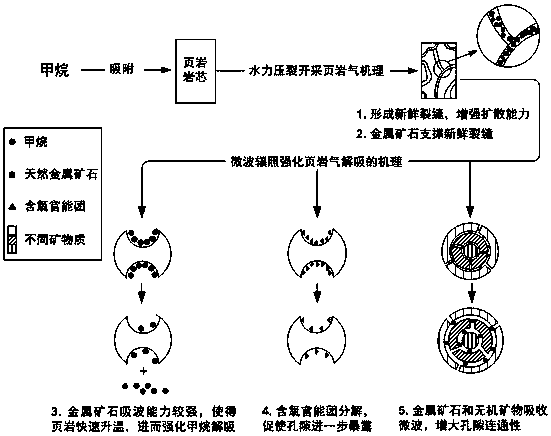

A shale gas and recovery rate technology, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of low utilization efficiency and low recovery rate of shale gas, and achieve strong microwave absorption capability. , Improve the efficiency of microwave energy utilization, improve the effect of oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

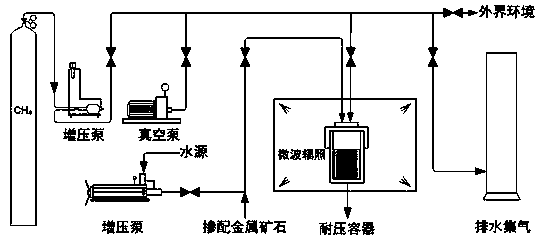

[0027] Embodiment 1: as figure 1 As shown, the method for enhancing shale gas recovery specifically includes the following steps:

[0028] (1) A water-bearing columnar dark mud shale sample is taken from a gas-bearing shale reservoir;

[0029] (2) Put the columnar shale sample into a pressure vessel;

[0030] (3) Use a vacuum pump to vacuumize the pressure vessel in step (2), so that the absolute pressure inside the pressure vessel is below 6 Pa, and the vacuuming time is 6 hours;

[0031] (4) Fill the pressure vessel in step (3) with 15 MPa of methane gas to promote the shale to fully absorb methane and reach the state of adsorption equilibrium;

[0032] (5) Hydraulically fracturing the columnar shale in the pressure vessel in step (4) with high-pressure water flow carrying proppant for primary exploitation of shale gas; the proppant is natural iron ore with a particle size of 20-60 mesh, the hydraulic fracturing pressure is 20 MPa, and the sand-carrying ratio is 15% (vol...

Embodiment 2

[0038] Embodiment 2: The method for enhancing shale gas recovery specifically comprises the following steps:

[0039] (1) A water-bearing columnar dark mud shale sample is taken from a gas-bearing shale reservoir;

[0040] (2) Put the columnar shale sample into a pressure vessel;

[0041] (3) Vacuumize the pressure vessel in step (2), so that the absolute pressure inside the pressure vessel is below 6 Pa, and the vacuuming time is 6 h;

[0042] (4) Fill the pressure vessel in step (3) with 18 MPa of methane gas to promote the shale to fully absorb methane and reach the state of adsorption equilibrium;

[0043] (5) The columnar shale in the pressure vessel in step (4) is subjected to hydraulic fracturing with high-pressure water flow carrying proppant for primary exploitation of shale gas. The proppant is natural iron ore with a particle size of 20-60 mesh, the hydraulic fracturing pressure is 24 MPa, and the sand-carrying ratio is 20% (volume ratio);

[0044] (6) Place the ...

Embodiment 3

[0049] Embodiment 3: the method for enhancing shale gas recovery specifically comprises the following steps:

[0050] (1) A water-bearing columnar high-carbon shale sample is taken from a gas-bearing shale reservoir;

[0051] (2) Put the columnar shale sample into a pressure vessel;

[0052] (3) Vacuumize the pressure vessel in step (2), so that the absolute pressure inside the pressure vessel is below 6 Pa, and the vacuuming time is 6 h;

[0053] (4) Fill the pressure vessel in step (3) with 21 MPa of methane gas to promote the shale to fully absorb methane and reach the state of adsorption equilibrium;

[0054] (5) Perform hydraulic fracturing of the columnar shale in the pressure vessel in step (4) with high-pressure water flow carrying proppant for primary exploitation of shale gas. The proppant is natural copper ore with a particle size of 20-60 mesh, the hydraulic fracturing pressure is 28 MPa, and the sand-carrying ratio is 25% (volume ratio);

[0055] (6) Place the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com