Oyster-shell soil conditioner, preparation method thereof and application of oyster-shell soil conditioner in rice planting

A technology of soil conditioner and oyster shell, which is applied in the field of oyster shell soil conditioner and its preparation, can solve the problems of unfavorable soil fertilization, high energy consumption, and high calcination temperature, and achieve the reduction of effective cadmium content and rice cadmium content , Improve the effect of microporous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

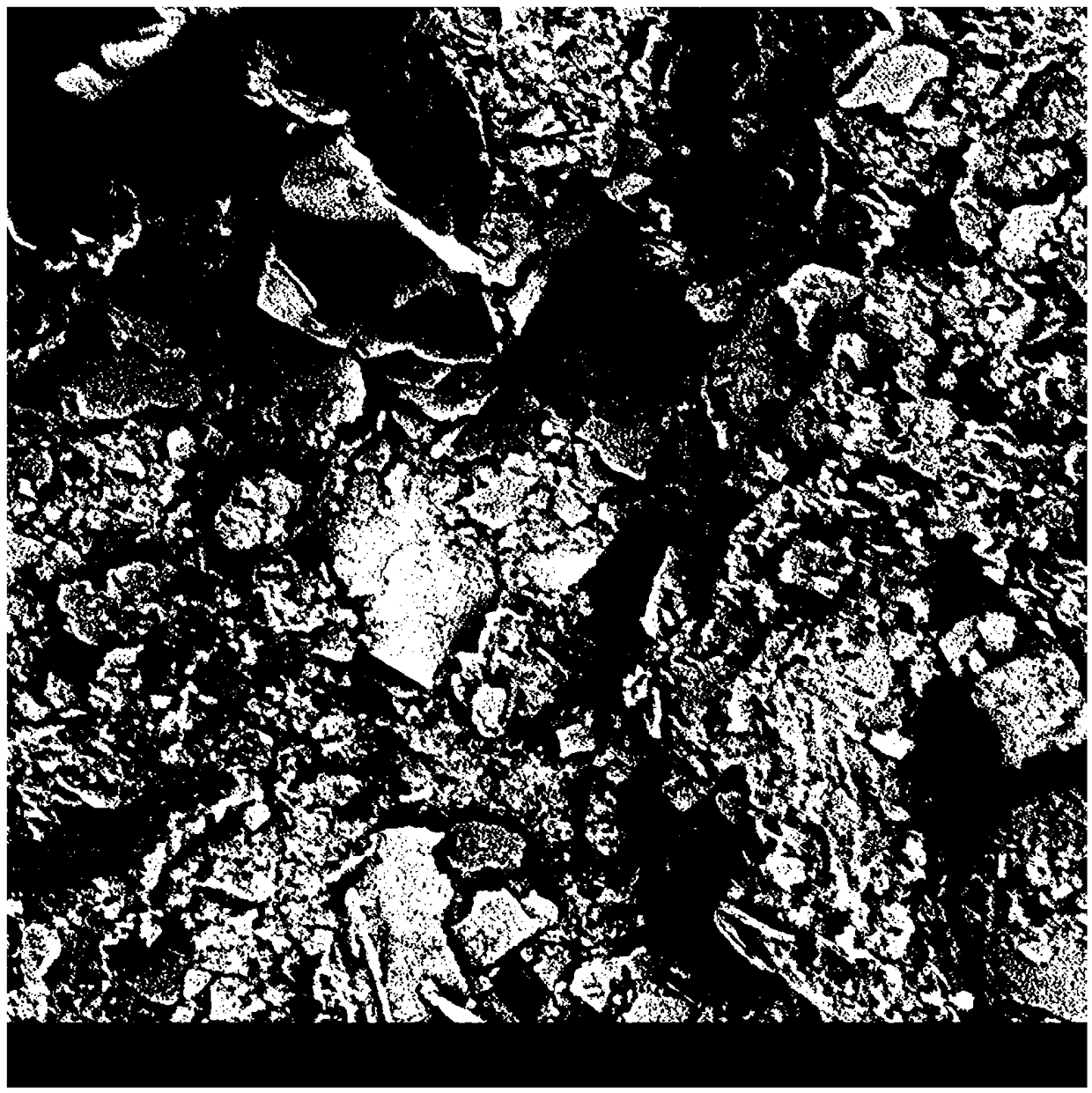

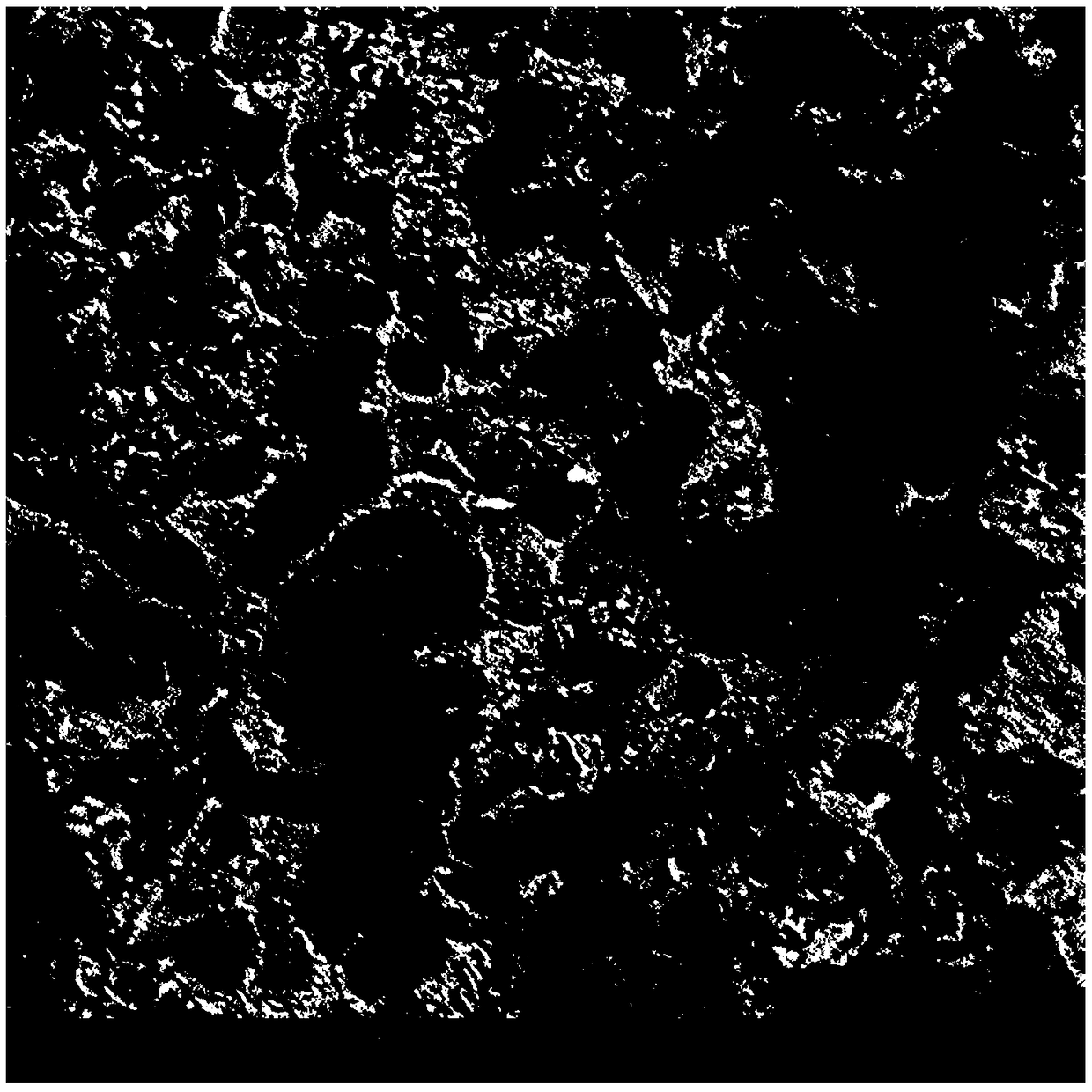

Image

Examples

Embodiment 1

[0031] (1) The oyster shells are sent into a high temperature furnace, firstly heated to 500°C at a heating rate of 20°C / min, kept for 10min, then heated to 1000°C at a temperature rise rate of 20°C / min, kept for 10min, and naturally cooled to room temperature Obtain stepped high temperature calcined oyster shells.

[0032] (2) Take and dry the fish and shrimp processing wastes to obtain organic matter.

[0033] (3) Mix 70 parts of oyster shells calcined at high temperature in a stepwise manner and 30 parts of organic matter, pulverize with an ultrafine pulverizer, and mix them evenly to prepare a mixture.

[0034] (4) the mixture of the previous step gained is input into the drum granulator to carry out steam granulation, the particle diameter is blown into the dryer with hot air after 1-2mm to dry the particles, and then continues to carry out steam granulation, the particle diameter After 4-5mm, the granules are dried by blowing hot air into the dryer to obtain the oyster ...

Embodiment 2

[0037] (1) The oyster shells are sent into the high-temperature furnace, firstly heated to 450°C at a heating rate of 20°C / min, maintained for 10min, then heated to 1030°C at a temperature increase rate of 20°C / min, maintained for 10min, and naturally cooled to room temperature Obtain stepped high temperature calcined oyster shells.

[0038] (2) The wastes from the shell and algae processing process are dried to obtain organic matter.

[0039] (3) Mix 75 parts of oyster shells calcined at a high temperature in a stepwise manner and 25 parts of organic matter, pulverize with an ultrafine pulverizer, and mix uniformly to prepare a mixture.

[0040] (4) the mixture of the previous step gained is input into the drum granulator to carry out steam granulation, the particle diameter is blown into the dryer with hot air after 1-2mm to dry the particles, and then continues to steam granulation, the particle diameter After 4-5mm, the granules are dried by blowing hot air into the dryer...

Embodiment 3

[0042] (1) The oyster shells are sent into the high-temperature furnace, firstly heated up to 530°C at a heating rate of 20°C / min, kept for 10 minutes, then heated to 980°C with a heating rate of 20°C / min, kept warm for 10 minutes, and naturally cooled to room temperature Obtain stepped high temperature calcined oyster shells.

[0043] (2) Dry the waste from the poultry breeding process to obtain organic matter.

[0044] (3) Mix 70 parts of oyster shells calcined at a high temperature in a stepwise manner and 30 parts of organic matter, pulverize with an ultrafine pulverizer, and mix evenly to prepare a mixture.

[0045] (4) the mixture of the previous step gained is input into the drum granulator to carry out steam granulation, the particle diameter is blown into the dryer with hot air after 1-2mm to dry the particles, and then continues to steam granulation, the particle diameter After 4-5mm, the granules are dried by blowing hot air into the dryer to obtain the oyster shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com