Thermal-insulating heat-preserving flame-retardant coating for exterior wall of building and preparation method thereof

A technology for heat insulation and building exterior walls, applied in the field of coatings, can solve problems such as easy peeling, poor moisture resistance and fire resistance, and high price, so as to suppress radiant heat and heat conduction, improve coating adhesion, and prevent heat conduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

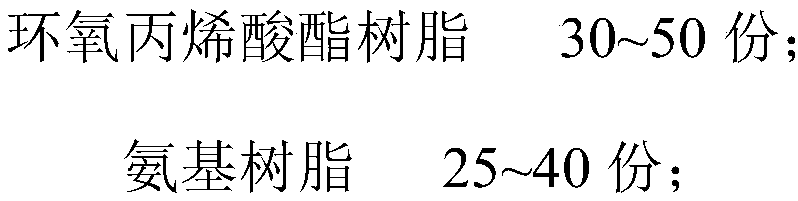

[0031] A heat-insulation and flame-retardant coating for building exterior walls, comprising the following raw materials in parts by weight:

[0032]

[0033]

[0034] The preparation method of the heat-insulating and flame-retardant coating for building exterior walls comprises the following steps:

[0035] (1) Under low-speed stirring at 1200r / min, sequentially add deionized water, glycerin, sodium hexametaphosphate, flame retardant char-forming agent, ammonium polyphosphate, rutile titanium dioxide, and then turn to 9000r / min Stir at high speed and continue to stir for 12 minutes;

[0036] (2) Then add expanded vermiculite, hollow glass microspheres, epoxy acrylate resin, amino resin, and continue to stir for 20min;

[0037] (3) Finally, add film-forming agent, dispersant, leveling agent, thickener, wetting agent, and defoamer, and continue stirring for 10 minutes to obtain the thermal insulation coating for building exterior walls.

Embodiment 2

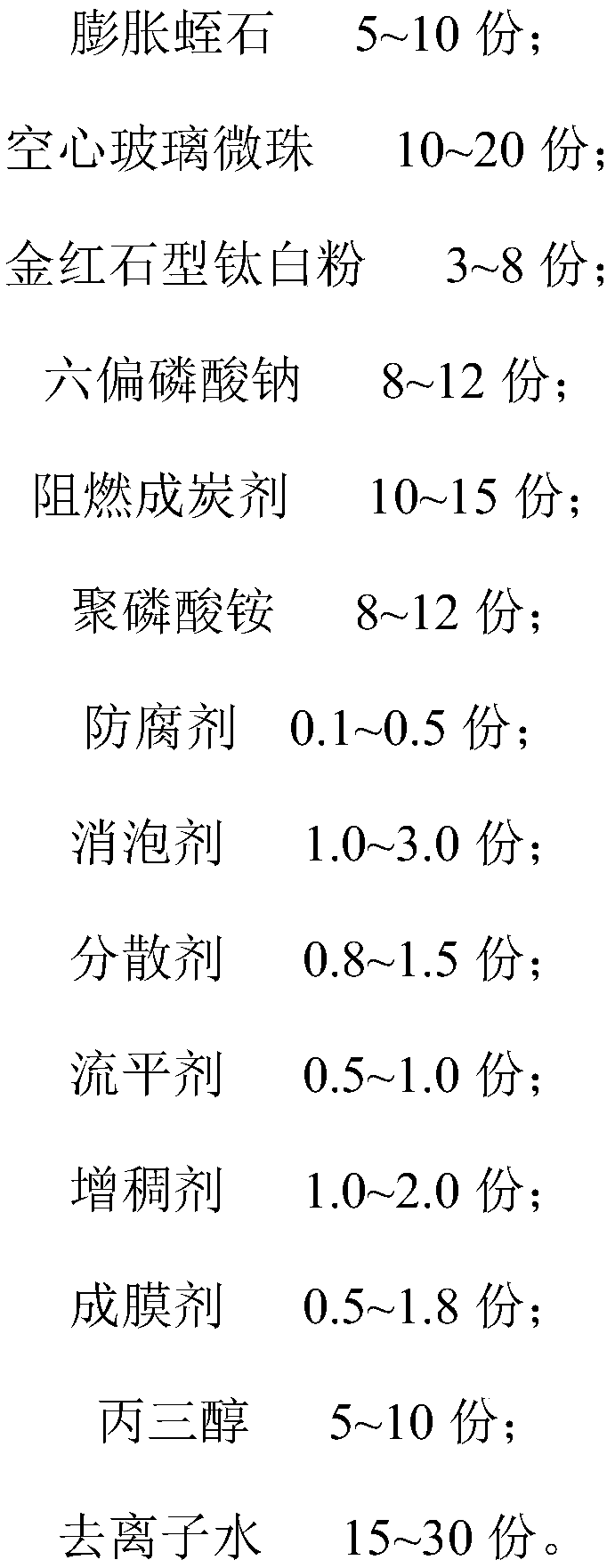

[0039] A heat-insulation and flame-retardant coating for building exterior walls, comprising the following raw materials in parts by weight:

[0040]

[0041] The preparation method of the heat-insulating and flame-retardant coating for building exterior walls comprises the following steps:

[0042] (1) Under 800 / min low-speed stirring, sequentially add deionized water, glycerin, sodium hexametaphosphate, flame retardant char-forming agent, ammonium polyphosphate, rutile titanium dioxide, and then turn to 8000r / min Stir at high speed and continue to stir for 20 minutes;

[0043] (2) Then add expanded vermiculite, hollow glass microspheres, epoxy acrylate resin, amino resin, and continue to stir for 30min;

[0044] (3) Finally, add film-forming agent, dispersant, leveling agent, thickener, wetting agent, and defoamer, and continue stirring for 20 minutes to obtain the thermal insulation coating for building exterior walls.

Embodiment 3

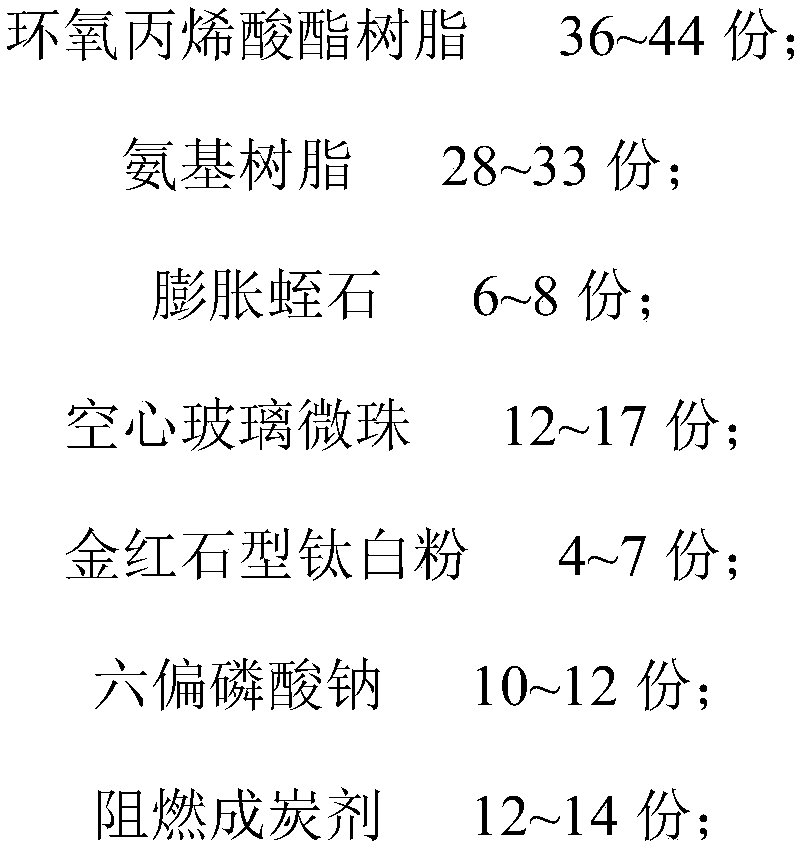

[0046] A heat-insulation and flame-retardant coating for building exterior walls, comprising the following raw materials in parts by weight:

[0047]

[0048] The preparation method of the heat-insulating and flame-retardant coating for building exterior walls comprises the following steps:

[0049] (1) Under 1500r / min low-speed stirring, sequentially add deionized water, glycerin, sodium hexametaphosphate, flame retardant char-forming agent, ammonium polyphosphate, rutile titanium dioxide, and then turn to 10000r / min Stir at high speed and continue to stir for 10 minutes;

[0050] (2) Then add expanded vermiculite, hollow glass microspheres, epoxy acrylate resin, amino resin, and continue to stir for 20min;

[0051] (3) Finally, add film-forming agent, dispersant, leveling agent, thickener, wetting agent, and defoamer, and continue stirring for 10 minutes to obtain the thermal insulation coating for building exterior walls.

[0052] The performance test results of coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com