Corrosion reinforcement self-repair composite coating

A composite coating, self-healing technology, applied in anti-corrosion coatings, coatings, radiation-absorbing coatings, etc., can solve the problems of reduced wave-absorbing performance of coatings, affecting the electromagnetic properties of absorbents, and overall peeling, to overcome corrosion, The effect of improving corrosion protection ability and improving corrosion resistance ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

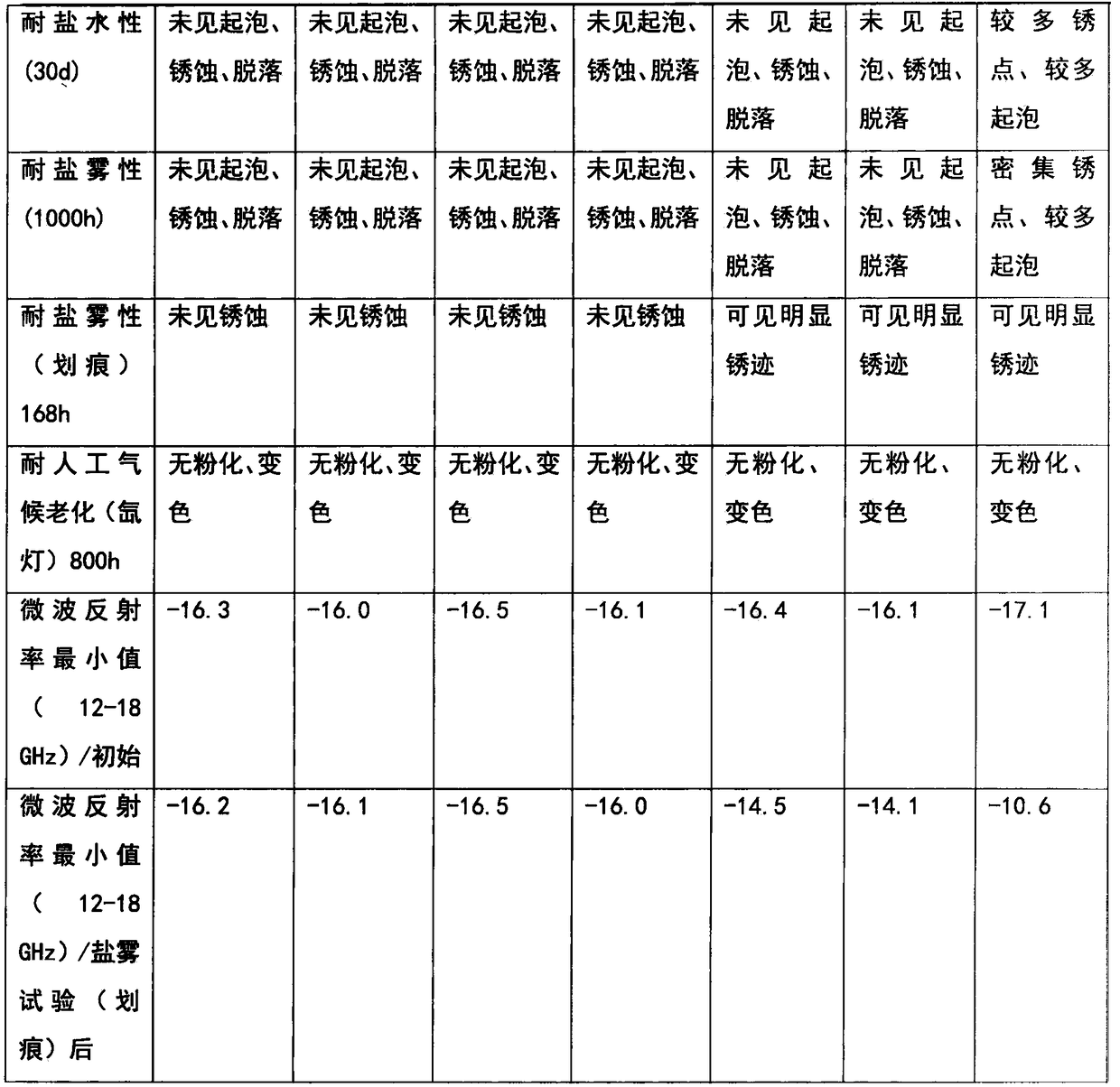

Examples

Embodiment 1

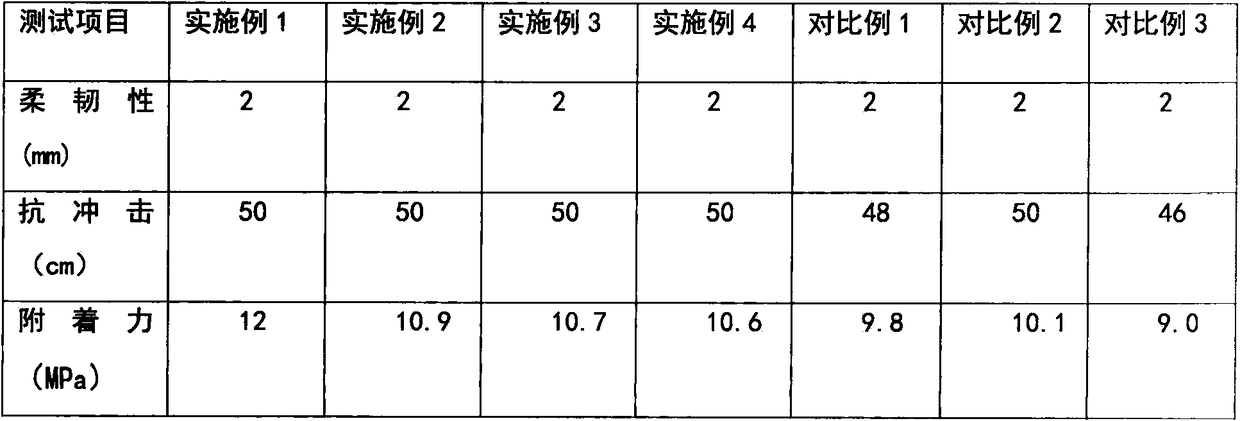

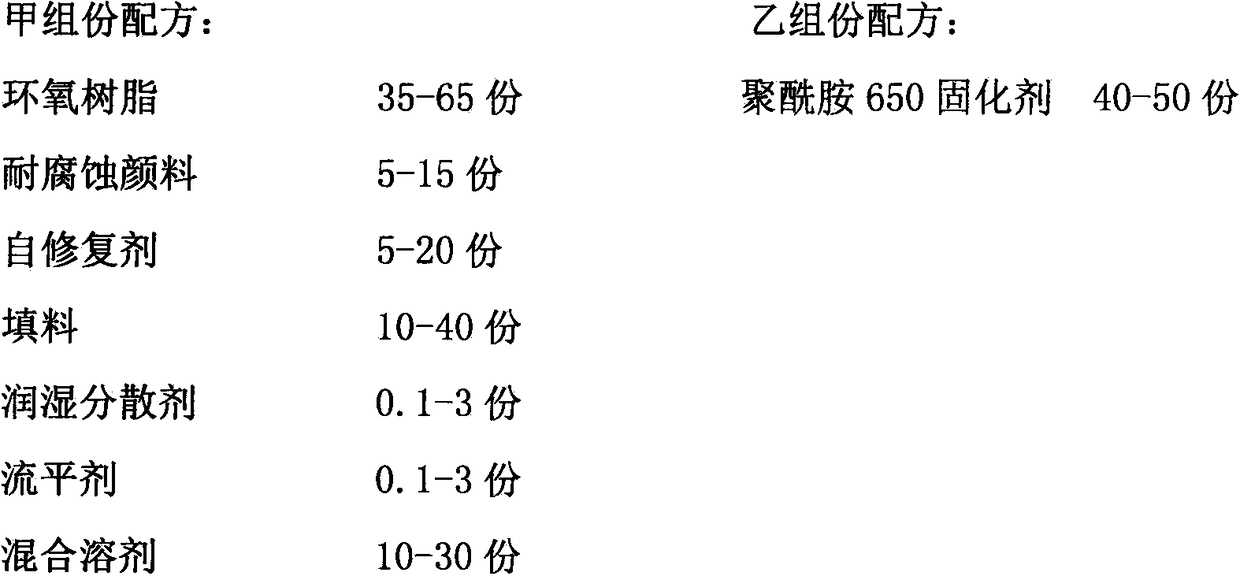

[0021] The coating adopts a bottom-surface double-layer structure design, and the formulation design of each layer of coating adopts a two-component system, which is weighed by weight percentage.

[0022] Primer coating ratio

[0023]

[0024] Component A resin is bisphenol A epoxy resin, the epoxy equivalent is between 210-450, it can be Huntsman 6101, Dow 671 or their mixture.

[0025] The anti-corrosion pigments and fillers in component A are compound zinc phosphate with a particle size of less than 3 microns, which can be BASF’s ZNP, Kaibai’s ZP-10, etc.

[0026] The self-healing agent in component A is an inorganic capsule structure material filled with a corrosion-inhibiting liquid. The specific preparation method: add 0.015g of hexadecyltrichlorosilane dropwise to 200ml of absolute ethanol, ultrasonically / stir, and slowly add 5ml of normal Ethyl silicate, after ultrasonic / stirring (peripheral linear speed of stirring blade 1-2 m / s), add 6ml of ammonia water and 50ml...

Embodiment 2

[0038] The preparation method and process are the same as in Example 1, only the composition ratio of the paint is changed.

[0039] Composite microwave absorbing coating primer formulation --- two-component epoxy polyamide system

[0040]

[0041]

[0042] Components A and B are mixed and used in percentage by weight according to epoxy equivalent: amine hydrogen equivalent = 1:1.

[0043] Composite microwave absorbing coating surface coating formula --- two-component acrylic polyurethane system

[0044]

[0045] Components A and B are mixed and used in percentage by weight according to epoxy equivalent: amine hydrogen equivalent = 1:1.

Embodiment 3

[0047] The preparation method and process are the same as in Example 1, only the composition ratio of the paint is changed.

[0048]Composite microwave absorbing coating primer formulation --- two-component epoxy polyamide system

[0049]

[0050]

[0051] Components A and B are mixed and used in percentage by weight according to epoxy equivalent: amine hydrogen equivalent = 1:1.

[0052] Composite microwave absorbing coating surface coating formula --- two-component acrylic polyurethane system

[0053]

[0054] Components A and B are mixed and used in percentage by weight according to epoxy equivalent: amine hydrogen equivalent = 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com