High efficient noctilucent master batch for shoe material and noctilucent shoe material

A high-efficiency, shoe-material technology, applied in the field of polymer materials, can solve the problems of destroying the lattice structure of luminous powder, low utilization rate of luminous powder, and failure of luminous powder, etc., and achieve the effect of broad market prospect, long luminous time and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

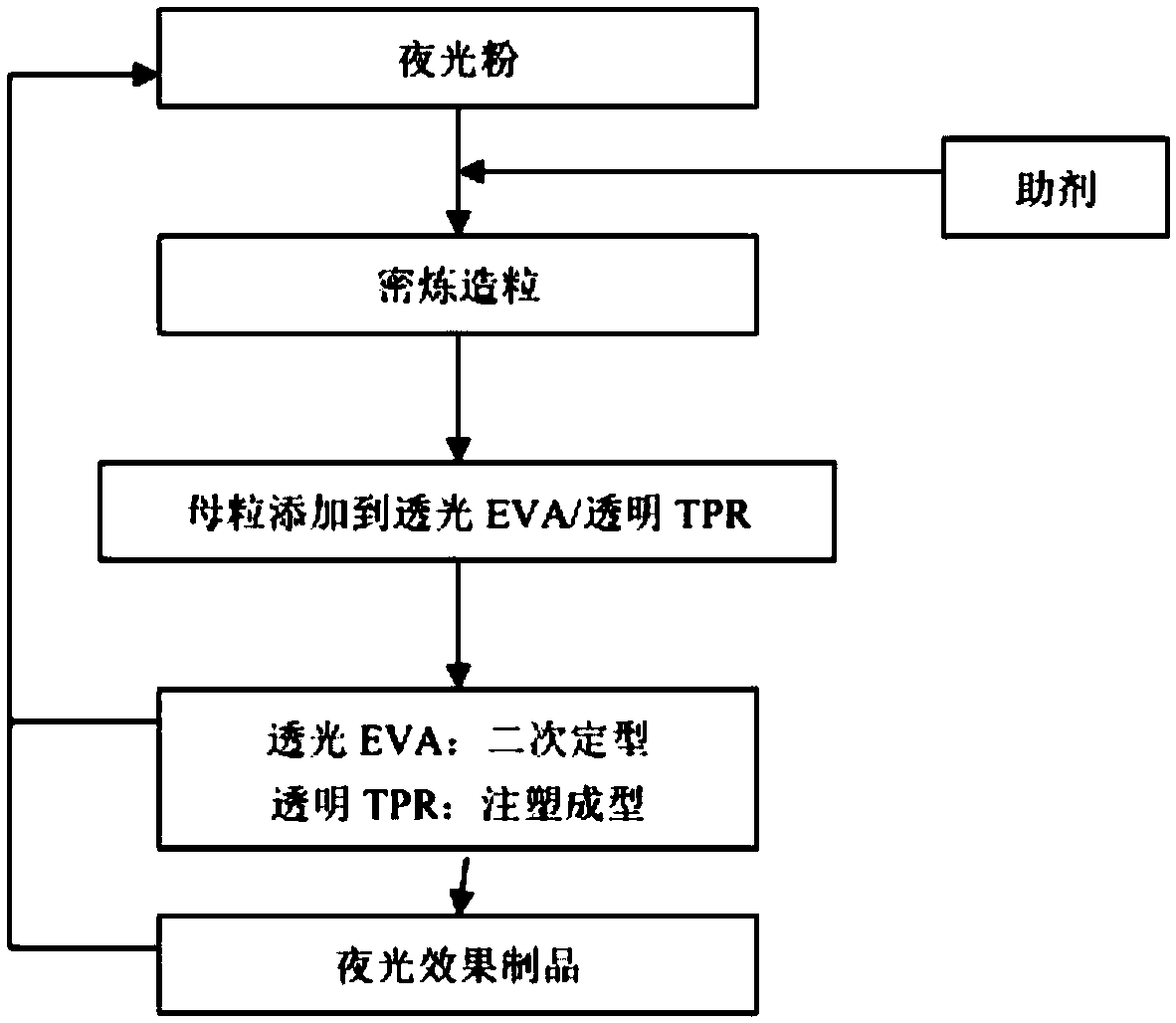

Method used

Image

Examples

Embodiment 1

[0060] By weight, the content of each component is:

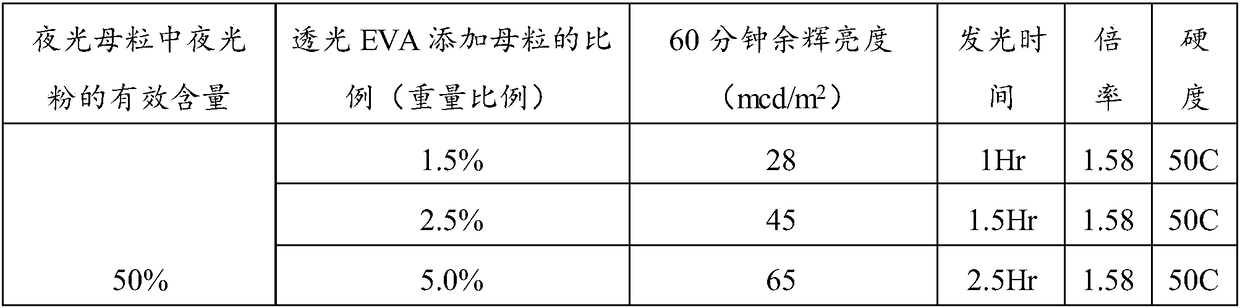

[0061] SBS (Li Changrong SBS3501) content 23%, naphthenic oil 4006 content 24%, boro-aluminate luminous powder (500 mesh) content 50%, 1010 content 0.1%, ethylene-vinyl acetate copolymer wax content 2%, dimethyl The content of base silane is 0.4%, and the metal blocking agent is 0.5%. After granulation, it is added into the light-transmitting foamed EVA material for banburying. According to different addition ratios, the light-transmitting EVA has different luminous time. As shown in Table 1,

[0062] Table 1 Performance of different addition ratios of luminous masterbatch in Example 1 of the present invention

[0063]

Embodiment 2

[0065] By weight, the content of each component is:

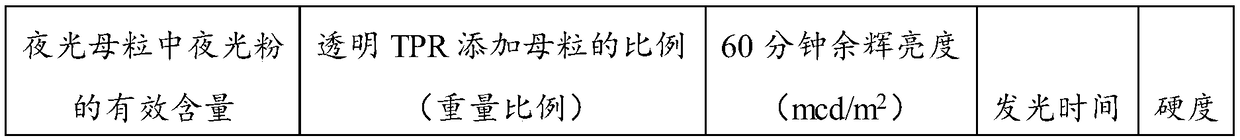

[0066] SBS (Yueyang Petrochemical SBS792) content 30%, naphthenic oil (Kelamayi 4006) content 32%, boro-aluminate luminous powder (250 mesh) content 35%, 1010 content 0.1%, 168 content 0.1%, polyethylene wax content 2%, dimethylsilane content 0.3%, metal blocking agent 0.5%, after granulation, added into transparent TPR material for injection molding. According to different addition ratios, transparent TPR has different luminous time, as shown in Table 2,

[0067] Table 2 Performance of different addition ratios of luminous masterbatch in Example 2 of the present invention

[0068]

[0069]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com