Microbiological treatment technology for oil-containing silt in oil field and processing system thereof

A microbial treatment, oil sludge sand technology, applied in the direction of biological sludge treatment, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of unrecoverable crude oil and long treatment period, and achieve short period and short treatment period , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

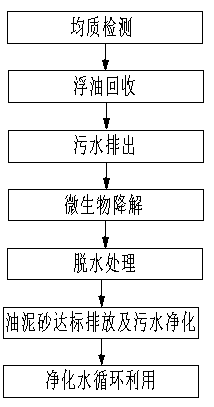

[0043] like figure 1 A kind of microbial treatment process of oilfield oily mud sand shown, comprises the following steps

[0044] Step 1: homogeneous detection

[0045] Inject the oil sludge sand to be treated into the microbial treatment device and mix it evenly to detect its oil content;

[0046] Step 2: Oil Slick Recovery

[0047] If the oil content of the oil sludge in the oil sludge sand is less than 5% by step 1, stir and mix the oil sludge sand evenly, inject clean water, and heat to 60-80°C, continue stirring, and after standing still, recover the upper oil slick through crude oil Device recycling;

[0048] If it is detected by step 1 that the oil content of the oil sludge is ≥ 5%, then stir and mix the oil sludge sand evenly, inject clean water, then add cleaning agents, and heat to 60-80°C, continue stirring, and after standing still, remove the upper oil slick Recycle and reuse through crude oil recovery unit;

[0049] Step 3: Sewage discharge

[0050] The se...

Embodiment 2

[0062] like figure 1 A kind of microbial treatment process of oilfield oily mud sand shown, differs from embodiment one in that:

[0063] Mix the tested oil sludge sand with an oil content of 10% evenly; use 5% sodium hydroxide solution, heat at 80°C, rotate at a speed of 40r / min, wash for 40min, and the crude oil removal rate is 50.55%; Bacillus (Bacillus encimensisstrain encimensis), Alcaligenesfaecalis strain, Pseudomonas stutzeri strain, Nocardioidesluteus, and Nocardioidesalbus The degrading bacteria are mixed according to the weight ratio of 1.5:1.5:1.5:3:2.5; nutrients such as carbon source, nitrogen source, inorganic salt and trace elements are added, and straw is added as a leavening agent to make a solid composite microbial agent. Add the above-mentioned solid composite microbial agent into the reaction tank, stir evenly, and keep it warm at about 30°C. Add the composite biological agent every 7 days, and the addition amount is the same as the first time; until the ...

Embodiment 3

[0065] like figure 1 A microbial treatment process for oily mud sand in the shown oilfield is different from Example 1 in that the microbial composite bacterial agent in the step 4 is composed of multiple strains of degrading bacteria and surfactant-producing bacteria. Multiple strains of degrading bacteria include Bacillus encimensis strain encimensis, Alcaligenesfaecalis strain, Pseudomonas stutzeri strain, Nocardioidesluteus and white Nocardioides albus is mixed at a weight ratio of 1.5:1.5:1.5:3:2.5.

[0066] Preferably, the nutrient in Step 4 includes any one or a combination of inorganic nitrogen, phosphorus, potassium, magnesium, calcium, iron or copper elements.

[0067] Preferably, the nutrient in step 4 includes inorganic nitrogen, phosphorus, potassium and the mass ratio of inorganic nitrogen, phosphorus, potassium to carbon content in the sludge is 5-10:1:1:100.

[0068] It is preferred that the dehydration treatment in the step 5 adopts natural drying or vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com