A method for preparing activated carbon by microwave-assisted hydrothermal treatment of Chinese fir bark

A microwave-assisted preparation of activated carbon, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of long preparation time of hydrothermal carbon materials, achieve shortened preparation time, mild reaction conditions, and no hysteresis effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

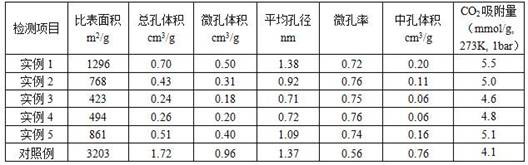

Embodiment 1

[0025] Take 2g of fir bark powder, put it in a glass beaker, add 6g of potassium hydroxide solid, then add 50ml of deionized water, then stir with a magnetic stirrer at a speed of 800r / min for 30min, and transfer the stirred mixed solution to a poly In a tetrafluoroethylene high-pressure reactor, place it in a microwave hydrothermal synthesizer under the condition of 180°C and 1.8MPa for the reaction, follow the temperature program for 10 minutes, then cool it down to room temperature naturally, take it out, and dry it in a vacuum oven at 105°C for 10 hours. Then put the dried powder in a sintering furnace at 500°C, sinter for 2 hours under nitrogen, pickle with 1M hydrochloric acid solution twice, then wash with deionized water until neutral, and get a Chinese fir bark after drying Microwave hydrothermal activated carbon.

Embodiment 2

[0027] Take 2g of fir bark powder, put it in a glass beaker, add 6g of potassium hydroxide solid, then add 50ml of deionized water, then stir with a magnetic stirrer at a speed of 800r / min for 30min, and transfer the stirred mixed solution to a poly In a tetrafluoroethylene high-pressure reaction kettle, place it in a microwave hydrothermal synthesizer under the condition of 180°C and 2MPa for the reaction, follow the programmed temperature rise for 15 minutes, then cool it down to room temperature naturally, take it out, and dry it in a vacuum oven at 105°C for 11 hours, then The dried powder is placed in a sintering furnace at 600°C, sintered under nitrogen for 2 hours, pickled twice with 1M hydrochloric acid solution, washed with deionized water until neutral, and dried to obtain a fir bark microwave Hydrothermal activated carbon.

Embodiment 3

[0029] Take 2g of fir bark powder, put it in a glass beaker, add 6g of potassium hydroxide solid, then add 50ml of deionized water, then stir with a magnetic stirrer at a speed of 800r / min for 30min, and transfer the stirred mixed solution to a poly In a tetrafluoroethylene high-pressure reaction kettle, place it in a microwave hydrothermal synthesizer under the condition of 180°C and 2MPa to carry out the reaction, follow the programmed temperature rise reaction for 20 minutes, then cool down to room temperature naturally, take it out and place it in a vacuum oven at 105°C to dry for 12 hours, and then Put the dried powder in a sintering furnace at 700°C, sinter for 2 hours under nitrogen, pickle with 1M hydrochloric acid solution twice, and then wash with deionized water until neutral. After drying, a fir bark microwave Hydrothermal activated carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com