Optical fiber and preparation method thereof

An optical fiber and quartz optical fiber technology, applied in the field of optical fiber and its preparation, can solve the problems of unsuitability for large-scale high-speed optical fiber drawing, low efficiency, slow curing rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

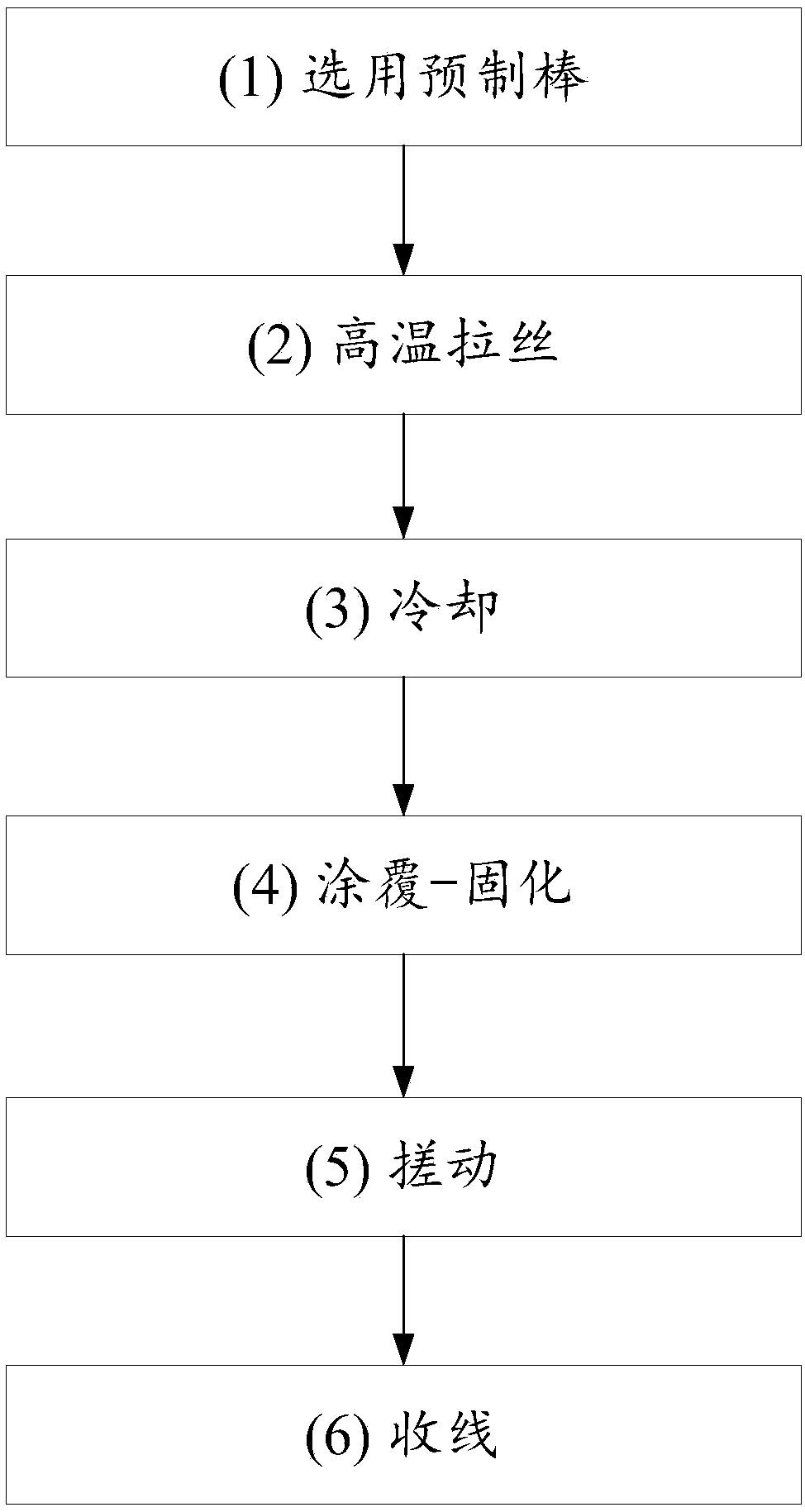

[0038] figure 1 is a schematic structural view of the optical fiber provided by the embodiment of the present invention. Such as figure 1 As shown, the optical fiber provided by the embodiment of the present invention includes a silica fiber in sequence from the inside to the outside. The silica fiber includes a core layer 1 and a cladding layer 2. The outer surface of the silica fiber is coated with an inner coating 3 and an outer coating 4 in sequence from the inside to the outside. The coating used in the inner coating 3 is a modified acrylic resin with a glass transition temperature of -50°C to -70°C, a refractive index of 1.4 to 1.5, and an elastic modulus of 0.3 to 0.5MPa after curing; the coating used in the outer coating 4 It is a modified acrylic resin, its refractive index is 1.5-1.6, and its elastic modulus after curing is above 800MPa. The coating used for the inner coating and the coating used for the outer coating have different refractive indices. Both the inn...

Embodiment 2

[0041] Such as figure 1 As shown, the optical fiber provided by the embodiment of the present invention includes a silica fiber in sequence from the inside to the outside. The silica fiber includes a core layer 1 and a cladding layer 2. The outer surface of the silica fiber is coated with an inner coating 3 and an outer coating 4 in sequence from the inside to the outside. The paint used in the inner coating 3 is a modified acrylic resin with a glass transition temperature of -70°C to -80°C, a refractive index of 1.4 to 1.5, a viscosity of 5000 to 6000cps, a viscosity of less than 1000cps at 60°C, and an elastic modulus after curing 0.3-0.5MPa, the elongation after curing is more than 150%, and the tensile strength is more than 0.3Mpa; the coating used in the outer coating 4 is a modified acrylic resin with a refractive index of 1.5-1.6 and a viscosity of 5000-5500cps. The viscosity at 60°C is less than 400cps, the elastic modulus after curing is above 800MPa, the elongation a...

Embodiment 3

[0044] Such as figure 1 As shown, the optical fiber provided by the embodiment of the present invention includes a silica fiber in sequence from the inside to the outside. The silica fiber includes a core layer 1 and a cladding layer 2. The outer surface of the silica fiber is coated with an inner coating 3 and an outer coating 4 in sequence from the inside to the outside. The coating used in the inner coating 3 is a modified acrylic resin, which is made of acrylic resin and a modifier with a content of 8%. The modifier is composed of polyethylene and styrene. The polyethylene here can be linear polyethylene or ring shaped polyethylene; the coating used in the outer coating 4 is a modified acrylic resin, made of acrylic resin and a modifier with a content of 5%, and the modifier is n-butyl acrylate. The coating used for the inner coating and the coating used for the outer coating have different refractive indices, and both the inner coating 3 and the outer coating 4 are formed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com