Modified medical polyester fiber and preparation method thereof

A polyester and modified technology, applied in the field of textile fibers, can solve problems such as the complex working environment of medical staff, achieve the effects of inhibiting bacterial growth, good color protection effect, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

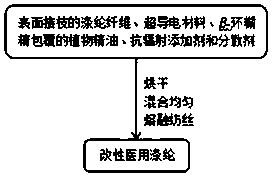

Method used

Image

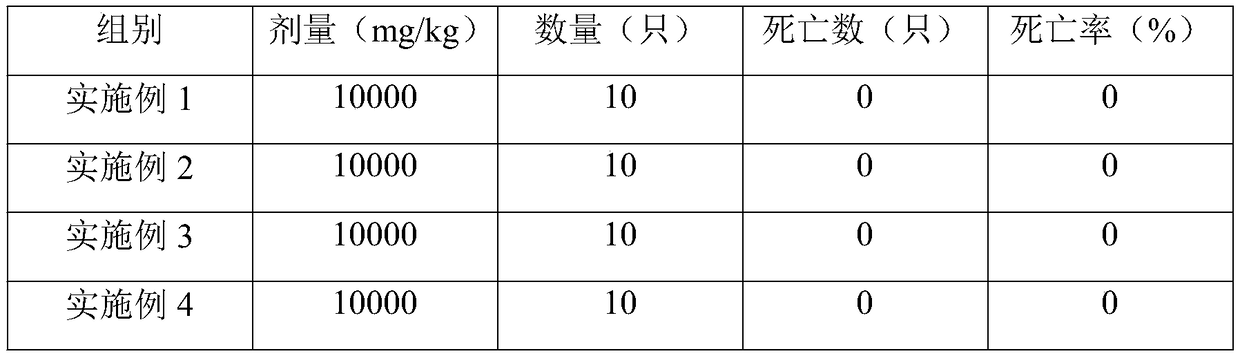

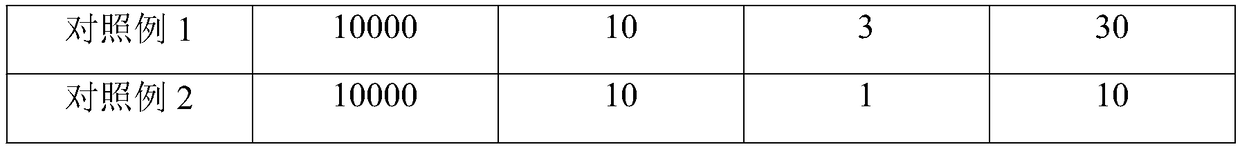

Examples

Embodiment 1

[0027] The preparation of embodiment 1 modified medical polyester

[0028] Raw material composition: 100 parts of surface-grafted polyester fiber, 10 parts of nickel-coated carbon fiber carbon black, 20 parts of cinnamon essential oil coated with β-cyclodextrin, 10 parts of micron-sized copper oxide, and 1 part of glyceryl tristearate;

[0029] Surface-grafted polyester fibers were prepared by the following method: weigh 100g of PET fibers, soak them in m-cresol at 40°C for 2h, wash with water and air-dry, and mix with 10mL 2mol / LK 2 CrO 4 Put the solution together in a conical flask, blow in nitrogen, and soak at constant temperature for 30min; then add 4mL 0.5mol / LH 2 SO 4 The solution and 5g of acrylamide were reacted at 70°C for 2 hours to obtain grafted fibers. The grafted fibers were soaked in deionized water, boiled at 100°C for 4 hours, taken out, and dried to obtain surface-grafted polyester fibers.

[0030] The plant essential oil coated with β-cyclodextrin was pr...

Embodiment 2

[0034] Embodiment 2 Preparation of modified medical polyester

[0035] Raw material composition: 150 parts of polyester fiber grafted on the surface, 10 parts of white carbon black, 10 parts of graphite, 40 parts of bergamot essential oil coated with β-cyclodextrin, 25 parts of methyl salicylate, 5 parts of barium stearate ;

[0036] Surface-grafted polyester fibers were prepared by the following method: Weigh 100g of PET fibers, soak them in m-cresol at 50°C for 2h, wash with water and air-dry, and mix with 10mL 3mol / LK 2 CrO 4 Put the solution together into the Erlenmeyer flask, pass through nitrogen, soak at constant temperature for 30min; then add 5mL 1.5mol / LH 2 SO 4 The solution and 15g of acrylamide were reacted at 90°C for 3 hours to obtain grafted fibers. The grafted fibers were soaked in deionized water, boiled at 100°C for 4 hours, taken out, and dried to obtain surface-grafted polyester fibers.

[0037] The plant essential oil coated with β-cyclodextrin was pre...

Embodiment 3

[0041] Embodiment 3 Preparation of modified medical polyester

[0042] Raw material composition: 120 parts of surface-grafted polyester fibers, 12 parts of carbon nanotubes, 25 parts of lavender essential oil coated with β-cyclodextrin, 15 parts of benzophenone, 2 parts of microcrystalline paraffin / stearic acid;

[0043] Surface-grafted polyester fibers were prepared by the following method: Weigh 100g of PET fibers, soak them in m-cresol at 40°C for 3 hours, wash with water and air-dry, and mix with 10mL 2.5mol / LK 2 CrO 4 Put the solutions together in a conical flask, blow in nitrogen, soak at constant temperature for 30min; then add 7mL 1mol / LH 2 SO 4 The solution and 10 g of acrylamide were reacted at 80° C. for 2.5 hours to obtain grafted fibers. The grafted fibers were soaked in deionized water, boiled at 100° C. for 4 hours, taken out, and dried to obtain surface-grafted polyester fibers.

[0044] β-cyclodextrin-coated plant essential oils were prepared by the followi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com